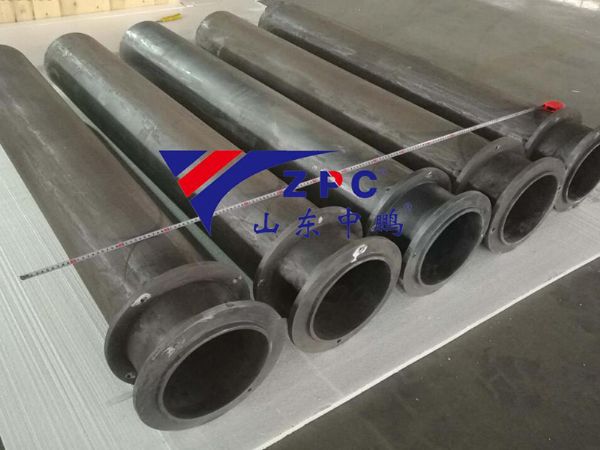

Bututun hasken silicon carbide

Bututun hasken silicon carbideAn san su da kayan aikin yumbu na zamani waɗanda aka san su da kyau saboda ƙwarewarsu ta musamman a aikace-aikacen masana'antu masu zafi da lalata. Abubuwan da suka keɓanta da kuma sauƙin daidaitawar tsarinsu sun sa su zama dole a cikin mawuyacin yanayi na aiki. Ga taƙaitaccen bayani game da manyan fa'idodinsu da aikace-aikacensu.

1. Kayayyakin Kayan Aiki Mafi Kyau

SiC wani abu ne mai ƙarfi da inganci wanda ke da halaye masu kyau:

(1) Juriyar Zafin Jiki Mai Tsanani: Yana da ikon ci gaba da aiki a yanayin zafi har zuwa 1600°C da kuma fallasa na ɗan gajeren lokaci fiye da 1800°C, wanda ya fi mafita na ƙarfe na gargajiya.

(2) Babban Tsarin Gudar da Zafi: Tare da ƙarfin watsa zafi sau 2-3 fiye da ƙarfe, bututun hasken silicon carbide suna ba da damar dumama cikin sauri da rarraba yanayin zafi iri ɗaya.

(3) Ƙarancin Faɗaɗawar Zafi: Ƙarancin faɗaɗawar zafinsu yana rage damuwa yayin canjin yanayin zafi, yana tabbatar da daidaiton tsarin.

(4) Juriyar Tsatsa da Iskar Shaka: Yana jure wa acid, alkalis, ƙarfe mai narkewa, da iskar gas mai ƙarfi, koda a cikin yanayi mai zafi mai tsawo.

2. Bambancin Tsarin

Ana iya tsara bututun radiant silicon carbide don dacewa da buƙatun masana'antu daban-daban:

(1) Zane-zanen da za a iya keɓancewa: Akwai su a cikin tsari madaidaiciya, siffar U, ko siffar W don inganta rarraba zafi da amfani da sarari.

(2) Haɗin gwiwa mai ƙarfi: Ya dace da flanges na ƙarfe ko tsarin rufewa na yumbu don haɗin da ba ya zubewa a cikin saitunan rikitarwa.

- Fa'idodin Aiki

(1) Ingantaccen Makamashi: Yawan amfani da zafi yana rage yawan amfani da makamashi ta hanyar ba da damar canja wurin zafi cikin sauri.

(2) Tsawon Rai: Bututun radiative na silicon carbide yawanci suna ɗaukar tsawon lokaci sau 3-5 fiye da na ƙarfe a cikin mawuyacin yanayi, wanda ke rage lokacin aiki da farashin maye gurbin.

(3) Juriyar Girgizar Zafi: Yana jure saurin zagayowar dumama da sanyaya ba tare da fashewa ba, wanda ya dace da hanyoyin da ke buƙatar canjin zafin jiki akai-akai.

4. Manyan Aikace-aikacen Masana'antu

Bututun radiative silicon carbide sun yi fice a fannoni masu mahimmanci:

(1) Ƙarfe: Ana amfani da shi a cikin tanderun da ke kunna wuta, tanderun da ke kunna wuta, da tsarin dumama don daidaita zafi.

(2) Sarrafa Sinadarai: Yana aiki azaman bututun amsawa ko tallafin mai kara kuzari a cikin masu amfani da wutar lantarki masu zafi da tanderun pyrolysis.

(3) Yumbu/Kayan Gilashi: Tabbatar da ingantaccen tsarin kula da zafin jiki a cikin murhun da ke narkewa da kuma tanderun narke gilashi.

(4) Tsarin Muhalli: An sanya shi a cikin na'urorin ƙona shara da na'urorin tace shara don sarrafa iskar gas mai lalata a yanayin zafi mai yawa.

5. Fa'idodi Masu Kwatantawa Fiye da Madadin:

| Mallaka | Bututun hasken silicon carbide | Bututun ƙarfe | Bututun Quartz |

| Matsakaicin Zafin Jiki | 1600℃ | <1200℃ | <1200℃(na ɗan gajeren lokaci) |

| Juriyar Tsatsa | Madalla sosai | Matsakaici | Ba shi da kyau a cikin yanayin alkaline |

| Juriyar Girgizar Zafi | Babban | Ƙasa | Matsakaici |

6. Me Yasa Zabi Bututun Radiant Silicon Carbide?

Bututun radiative na silicon carbide sune mafi kyawun zaɓi ga masana'antu waɗanda ke fifita fifikon su:

(1) Tsayin zafin jiki mai tsanani ba tare da lalacewar aiki ba.

(2) Aminci na dogon lokaci a cikin yanayi mai lalata ko iskar oxygen.

(3) Dumama mai inganci da daidaito don hanyoyin da aka tsara daidai.

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.