IiNozzles zeSilicon Carbide FGD Spray

IiNozzles zokufunxa igesi ephuma kwiFlue Gas Desulfurization (FGD)

Ukususwa kwee-sulfur oxides, ezibizwa ngokuba yi-SOx, kwiigesi zokukhupha umoya kusetyenziswa i-alkali reagent, njenge-limestone slurry emanzi.

Xa amafutha efosili esetyenziswa kwiinkqubo zokutsha ukuqhuba iibhoyila, ii-oven, okanye ezinye izixhobo, anokukwazi ukukhupha i-SO2 okanye i-SO3 njengenxalenye yegesi ephumayo. Ezi sulfur oxides zisabela ngokulula nezinye izinto ukuze zenze i-compound enobungozi efana ne-sulfuric acid kwaye zinokuba nefuthe elibi kwimpilo yabantu nakwindalo esingqongileyo. Ngenxa yezi ziphumo zinokwenzeka, ulawulo lwale compound kwiigesi ze-flue luyinxalenye ebalulekileyo yezityalo zamandla ezisebenzisa amalahle kunye nezinye izicelo zoshishino.

Ngenxa yokukhukuliseka, ukuvalwa, kunye nokwakheka, enye yezona nkqubo zithembekileyo zokulawula le nkunkuma yinkqubo ye-open-tower wet flue gas desulfurization (FGD) esebenzisa ilitye lekalika, ilime emanzi, amanzi olwandle, okanye esinye isisombululo se-alkaline. Ii-spray nozzles ziyakwazi ukusasaza ezi slurry ngokufanelekileyo nangokuthembekileyo kwiinqaba zokufunxa. Ngokwenza iipateni ezifanayo zamaconsi anobukhulu obufanelekileyo, ezi nozzles ziyakwazi ukudala ngokufanelekileyo indawo yomphezulu efunekayo ukuze kufunxwe ngokufanelekileyo ngelixa zinciphisa ukufakwa kwesisombululo sokukhuhla kwigesi ye-flue.

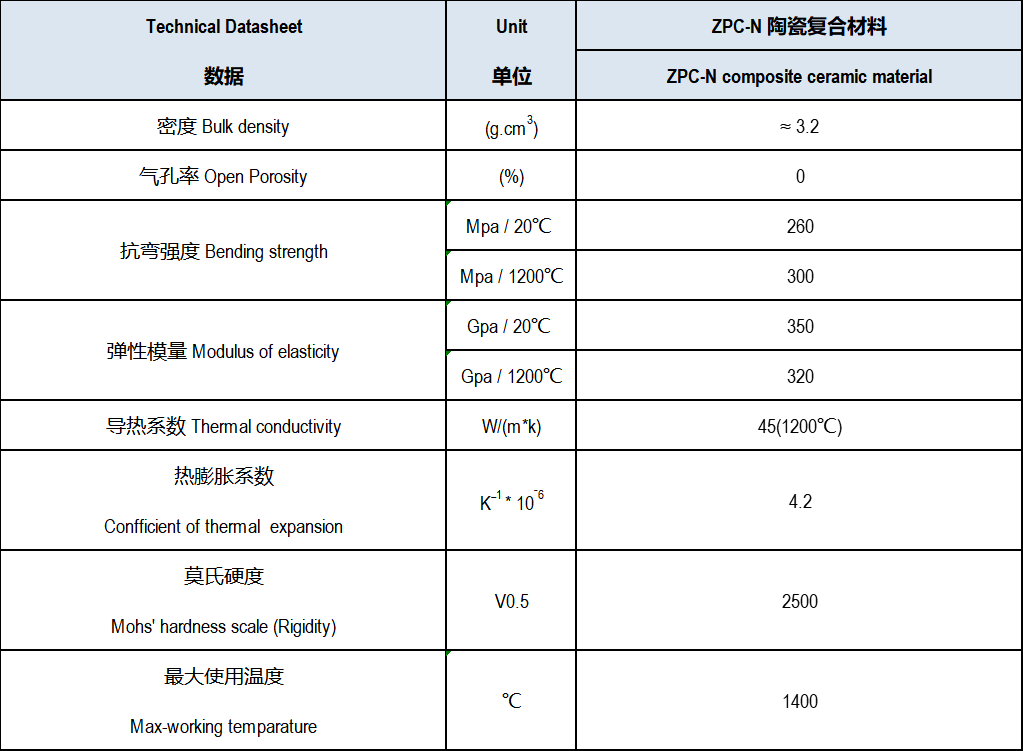

Izinto ezikwiphepha ledatha le-RBSiC Nozzles

Ukukhetha i-FGD Absorber Nozzle:

Izinto ezibalulekileyo ekufuneka ziqwalaselwe:

Uxinano lwemidiya yokuhluza kunye ne-viscosity

Ubungakanani bethontsi elifunekayo

Ubungakanani obuchanekileyo bethontsi bubalulekile ukuqinisekisa amazinga afanelekileyo okufunxa

Izinto zomlomo

Njengoko igesi yolwelo idla ngokuba yirhabaxa kwaye ulwelo lokuhlikihla luhlala luyirhabaxa enomxholo ophezulu wezinto eziqinileyo kunye neempawu zokurhawuzelela, ukukhetha izinto ezifanelekileyo zokurhawuzelela nokuguguleka kubalulekile.

Ukumelana nokuvaleka kwempumlo

Njengoko ulwelo lokuhlafuna ludla ngokuba ludaka olunezithako eziphezulu zezinto eziqinileyo, ukukhetha umlomo womlomo ngokubhekiselele ekungaxinaniseni amanzi kubalulekile.

Ipateni yesitshizi se-nozzle kunye nokubekwa kwayo

Ukuze kuqinisekiswe ukufunxwa ngokufanelekileyo, ukugubungela ngokupheleleyo umjelo wegesi ngaphandle kokudlula kunye nexesha elaneleyo lokuhlala kubalulekile

Ubungakanani boqhagamshelo lwe-nozzle kunye nohlobo

Amanqanaba okuhamba kolwelo okufunekayo ekucoceni

Ukwehla koxinzelelo olufumanekayo (∆P) kwimpumlo

∆P = uxinzelelo lombane kwindawo yokungena kwe-nozzle – uxinzelelo lwenkqubo ngaphandle kwe-nozzle

Iinjineli zethu ezinamava zinokukunceda umisele ukuba yeyiphi i-nozzle eza kusebenza njengoko kufuneka ngeenkcukacha zakho zoyilo

Ukusetyenziswa kweNozzle yeFGD Absorber kunye neMizi-mveliso:

Izityalo zamandla ezisebenzisa amalahle nezinye izinto ezisebenzisa amafutha efosili

Iindawo zokucoca ipetroliyam

Izixhobo zokutshisa inkunkuma zikamasipala

Ii-oven zesamente

Abanyibilikisi besinyithi

Ii-nozzles ze-SNBSC kunye ne-RBSC:

I-Silicon Nitride eBonded Silicon Carbide (SNBSC):

Izinto zeseramikhi ezinokumelana kakuhle nokukhukuliseka kunye nokugqwala. Imodulus ephantsi yokuqhekeka (MOR) kunye nokungamelani kakuhle nempembelelo zithintela izinto kwimizobo elula ngokwesakhiwo eneendawo ezinzima zodonga. I-SNBSC idla ngokusetyenziselwa ii-nozzles ze-hollow cone, ezijikelezayo.

I-Reaction Bonded Silicon Carbide (RBSC/SiSiC):

Yinto yodongwe enokumelana kakuhle nokukhukuliseka kunye nokugqwala. Ngenxa yokuba i-MOR ye-RBSC iphindwe ka-5-7 kune-SNBSC, ingasetyenziselwa iimilo ezintsonkothileyo ngakumbi.

I-RBSC isengozini yokungaphumeleli, kuba yenziwe nge-ceramic ebuthathaka. Xa imilomo ingaphumeleli, mhlawumbi iya kusilela ngenxa yokwaphuka. Oku kuqhekeka kunokubangelwa ziinkqubo zokufakela ezingalunganga, ukujiya koxinzelelo (ihamile yamanzi) ngexesha lokuqalisa, ukuzama ukucoca imilomo exhunyiweyo okanye eminye imisebenzi yokulungisa eqhelekileyo.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.