Feshin bututun silicon carbide FGD

Bututun Shakar Iskar Gas Mai Tsaftacewa (FGD)

Cire sinadarin sulfur oxides, wanda aka fi sani da SOx, daga iskar gas mai fitar da hayaki ta amfani da sinadarin alkali, kamar sinadarin limestone mai danshi.

Idan aka yi amfani da man fetur na burbushin halittu a cikin hanyoyin konewa don sarrafa boilers, tanderu, ko wasu kayan aiki, suna da damar sakin SO2 ko SO3 a matsayin wani ɓangare na iskar shaye-shaye. Waɗannan sulfur oxides suna amsawa cikin sauƙi tare da wasu abubuwa don samar da mahaɗi mai cutarwa kamar sulfuric acid kuma suna da yuwuwar yin mummunan tasiri ga lafiyar ɗan adam da muhalli. Saboda waɗannan tasirin da za a iya samu, sarrafa wannan mahaɗin a cikin iskar gas mai ƙarfi muhimmin ɓangare ne na cibiyoyin wutar lantarki na kwal da sauran aikace-aikacen masana'antu.

Saboda matsalolin zaizayar ƙasa, toshewa, da taruwar ruwa, ɗaya daga cikin ingantattun tsarin da za a iya sarrafa waɗannan hayaki shine tsarin cire sulfurization na iskar gas mai buɗaɗɗen hasumiya (FGD) ta amfani da farar ƙasa, lemun tsami mai laushi, ruwan teku, ko wani maganin alkaline. Feshi bututun feshi suna iya rarraba waɗannan slurries yadda ya kamata da aminci zuwa hasumiyoyin sha. Ta hanyar ƙirƙirar alamu iri ɗaya na digo mai kyau, waɗannan bututun suna iya ƙirƙirar yankin saman da ake buƙata don sha mai kyau yayin da suke rage shigar da maganin gogewa cikin iskar gas.

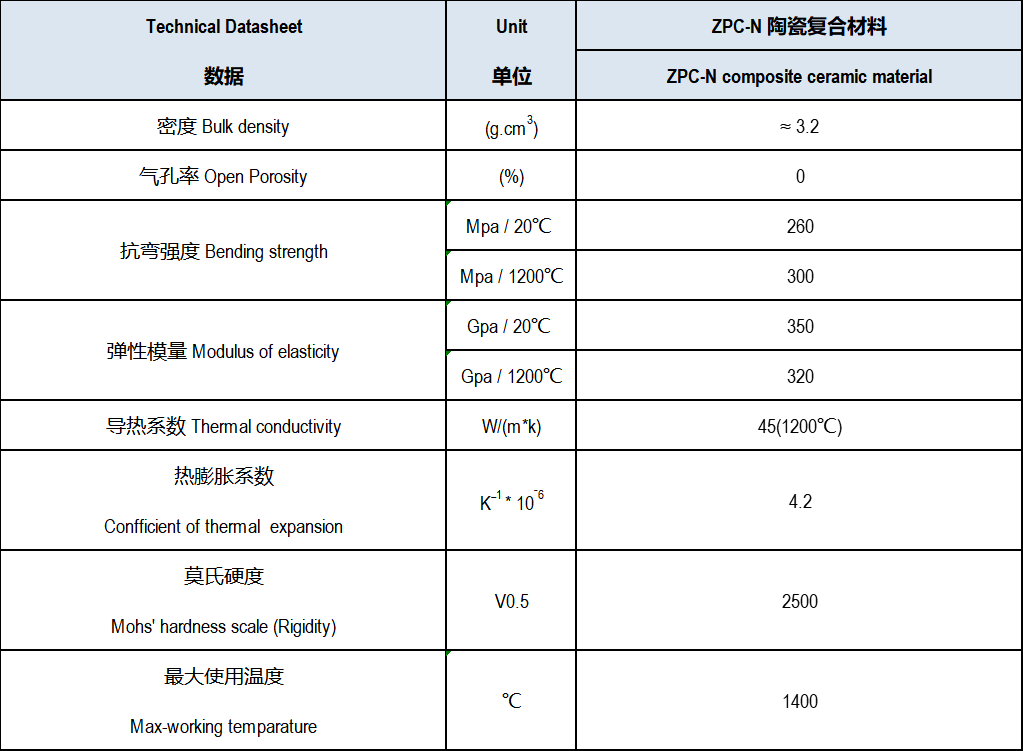

Kayan Takardar Bayanan Nozzles na RBSiC

Zaɓar bututun mai ɗaukar FGD:

Muhimman abubuwan da za a yi la'akari da su:

Goge yawan kafofin watsa labarai da danko

Girman digo da ake buƙata

Daidaitaccen girman digo yana da mahimmanci don tabbatar da ingantaccen yawan shan ruwa

Kayan bututun ƙarfe

Ganin cewa iskar gas ɗin sau da yawa tana lalata iskar kuma ruwan gogewa sau da yawa yana da laushi mai yawan danshi da kuma abubuwan da ke lalata iskar, zaɓar kayan da suka dace don tsatsa da kuma jure lalacewa yana da mahimmanci.

Juriyar toshewar bututun ƙarfe

Ganin cewa ruwan gogewa yawanci yana da sinadarin slurry mai yawan daskararru, zaɓin bututun ƙarfe dangane da juriyar toshewa yana da mahimmanci

Tsarin feshi da kuma sanya bututun feshi

Domin tabbatar da isasshen sha yana da mahimmanci a rufe cikakken rafin iskar gas ba tare da wucewa ba kuma a sami isasshen lokacin zama.

Girman da nau'in haɗin bututun ƙarfe

Yawan kwararar ruwa da ake buƙata

Rage matsin lamba da ake samu (∆P) a fadin bututun

∆P = matsin lamba a cikin bututun ƙarfe - matsin lamba a wajen bututun ƙarfe

Injiniyoyinmu masu ƙwarewa za su iya taimakawa wajen tantance wane bututun ƙarfe zai yi aiki kamar yadda ake buƙata tare da cikakkun bayanai game da ƙirar ku

Amfani da bututun fesawa na FGD da Masana'antu da aka saba amfani da su:

Kwal da sauran cibiyoyin samar da makamashin mai

Matatun mai

Masu ƙona sharar gida na birni

Murhun siminti

Masu narkar da ƙarfe

Bututun SNBSC da RBSC:

Silicon Nitride Bonded Silicon Carbide (SNBSC):

Kayan yumbu mai matuƙar juriya ga zaizayar ƙasa da tsatsa. Ƙaramin ƙarfin fashewa (MOR) da rashin ƙarfin juriya ga tasiri yana iyakance kayan zuwa ƙira mai sauƙi tare da sassan bango masu nauyi. Ana amfani da SNBSC yawanci don bututun ƙarfe masu rami, masu juyawa.

Reaction Bonded Silicon Carbide (RBSC/SiSiC):

Kayan yumbu mai matuƙar juriya ga zaizayar ƙasa da tsatsa. Domin kuwa MOR na RBSC ya ninka na SNBSC sau 5-7, ana iya amfani da shi don siffofi masu rikitarwa.

RBSC na iya fuskantar matsalar lalacewar bututun, saboda an yi su ne da yumbu mai karyewa. Idan bututun suka lalace, wataƙila za su lalace saboda karyewar bututun. Wannan karyewar na iya faruwa ne sakamakon rashin kyawun hanyoyin shigarwa, ƙarar matsin lamba (hammer ruwa) yayin farawa, ƙoƙarin tsaftace bututun da aka toshe ko wasu ayyukan gyara na yau da kullun.

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.