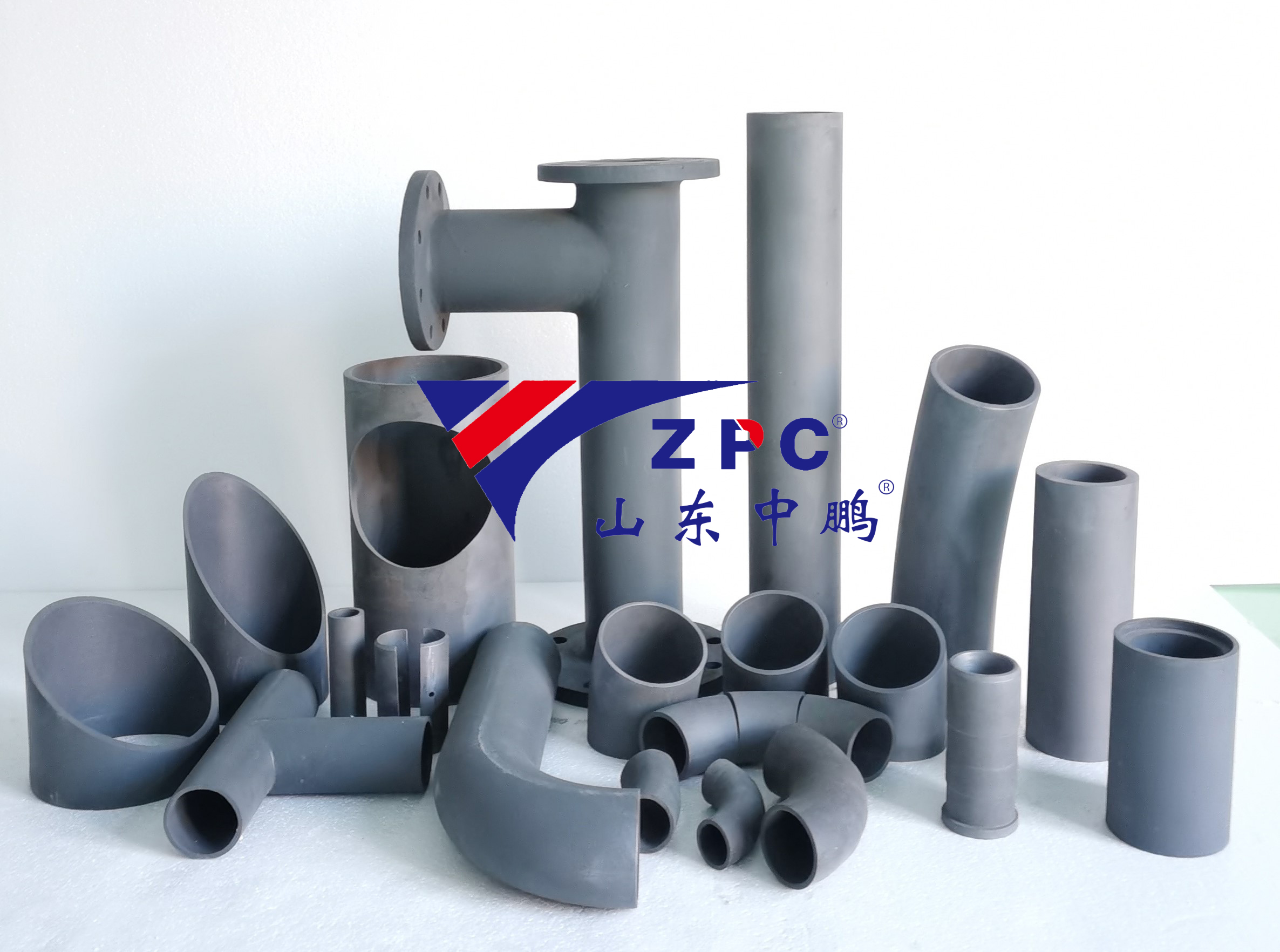

Nxiba iipayipi ze-silicon carbide ze-ZPW ezingamelaniyo, iithayile, iipleyiti, iigophe, iingqiniba

I-lining enganyangekiyo, i-lining plate kunye ne-cyclone esetyenziswa kwimigodi yamalahle

Imibhobho ye-ceramic ene-Silicon Carbide:

![]() I-ZPW-Silicon Carbide ceramic yinto efanelekileyo yokumelana nokuguguleka, efanelekileyo ngokukodwa kwi-abrasive enamandla, amasuntswana arhabaxa, ukwahlulahlula, ukugxila, ukuphelelwa ngamanzi emzimbeni kunye neminye imisebenzi.

I-ZPW-Silicon Carbide ceramic yinto efanelekileyo yokumelana nokuguguleka, efanelekileyo ngokukodwa kwi-abrasive enamandla, amasuntswana arhabaxa, ukwahlulahlula, ukugxila, ukuphelelwa ngamanzi emzimbeni kunye neminye imisebenzi.

Isetyenziswa kakhulu kushishino lwemigodi, kushishino lwentsimbi, kushishino lokucubungula iikorale, nakwimichiza

ishishini, ishishini lokwenza izinto eziluhlaza, ukutywinwa koomatshini, unyango olugqunywe ngesanti kunye ne-reflector yomphezulu njl. Ubulukhuni obuhle kunye nokumelana nokurhawuzelela, inokukhusela ngokufanelekileyo indawo apho kufuneka ukhuseleko lokuguguleka, ukuze yandise ubomi benkonzo yezixhobo.

■Iinkcukacha:

| Into | Iyunithi | Idatha |

| Ubushushu bokusetyenziswa | ℃ | 1380℃ |

| Uxinano | G/cm3 | >3.02 |

| I-Porosity evulekileyo | % | 0.1 |

| Amandla okugoba -A | I-Mpa | 250 (20℃) |

| Amandla okugoba -B | I-MPa | 280 (1200℃) |

| Imodulus ye-elasticity-A | I-GPa | 330(20℃) |

| Imodulus yokuthamba -B | I-GPa | 300 (1200℃) |

| Ukuqhuba kobushushu | W/mk | 45 (1200℃) |

| I-coefficient yokwandiswa kobushushu | K-1 ×10-6 | 4.5 |

| Ukuqina | / | 13 |

| I-alkaline engangeni asidi | / | ibalasele kakhulu |

■Imilo kunye nobukhulu obufumanekayo:

Ubukhulu: ukusuka kwi-6mm ukuya kwi-25mm

Imilo eqhelekileyo: Ipleyiti ye-SISIC, iPipe ye-SISIC, iiSiSiC Three Links, i-SISIC Elbow, i-SISIC Cone Cyclone.

Isaziso: Ezinye iisayizi kunye nemilo ziyafumaneka xa ziceliwe.

■Ukupakisha:

Kwibhokisi yebhokisi, ipakishwe kwipalethi yomthi efunxwayo enobunzima obuyi-20-24MT/20′FCL.

■Iingenelo eziphambili:

1. Ukumelana nokuguguleka okugqwesileyo, ukumelana neempembelelo kunye nokumelana nokugqwala;

2. Ukuthe tyaba okugqwesileyo kunye nokumelana okuhle kobushushu ukuya kuthi ga kwi-1350℃

3. Ukufakelwa okulula;

4. Ubomi benkonzo ende (bungaphezulu ngokuphindwe kasixhenxe kunobo be-alumina ceramic kwaye bungaphezulu ngokuphindwe kalishumi kunobo be-alumina ceramic

i-polyurethane

Uyilo lwepayipi ene-ceramic lining:

Izinto zobumba: RBSiC, SiSiC, SSiC, 99.5% Alumina, 99% Alumina, 95% alumina

- Iipayipi, imveliso iyonke;

- Iipleyiti, ipleyiti ekhazimlayo

- Iithayile, iithayile zeseramikhi.

Ipateni yokukrala kwempembelelo ye-engile Ukukrala okutyibilikayo kwe-engile ephantsi

Xa ukuhamba kwezinto ezirhabaxa kubetha umphezulu ogugileyo kwi-engile enganzulu okanye kudlula ngaxeshanye nawo, uhlobo lokuguguleka oluvela kwi-frocchini lubizwa ngokuba yi-sliding abrasion.

Iiceramics ze-silicon carbide eziphambili zibonelela ngokumelana nokuguguleka kunye nokumelana nokugqwala kweethayile ze-ceramic kunye ne-lining. Ezi mveliso ziye zangqinwa ukuba ziguguleka kwezixhobo kwinkqubo yokuhambisa, yokucubungula, kunye neyokugcina. Iithayile zethu zinokuveliswa ngobukhulu obuvela kwi-8 ukuya kwi-45mm. Kubalulekile ukuqinisekisa ukuba unokufumana iimveliso ezifunekayo. I-SiSiC: Ubunzima bukaMoh buyi-9.5 (Ubunzima bukaMoh obutsha buyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokuchasana ne-oxidation. Bunamandla ngokuphindwe ka-4 ukuya ku-5 kune-nitride bonded silicon carbide. Ubomi benkonzo bubude ngokuphindwe ka-5 ukuya ku-7 kune-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezintsonkothileyo. I-lining ye-ceramic enganyangekiyo iyasebenza ukuphucula ukusebenza kwemveliso, ukusebenza kakuhle, ukunciphisa iindleko zokugcina kunye nokunyusa inzuzo.

Iiceramics ezichanekileyo zinolwazi lwezinto eziphathekayo, ubuchule obusetyenzisiweyo kunye nezakhono zobunjineli. Oku kunokuqinisekisa ngokufanelekileyo ukuba izisombululo ezilungileyo zinikezelwa kubathengi bethu. Iithayile ze-silicon carbide ceramic kunye ne-lining zihlala zisetyenziswa kwizicelo ezifana nee-cyclones, iityhubhu, ii-chutes, ii-hoppers, iipayipi, ii-conveyor belts kunye neenkqubo zemveliso. Kwinkqubo, kukho izinto ezihambayo ezityibilikayo phezu komphezulu. Xa into ityibilika kwisixhobo, idlakadlaka kancinci iindawo kude kungabikho nto isalayo. Kwiindawo ezigugileyo kakhulu, oku kunokwenzeka rhoqo kwaye kubangele iingxaki ezininzi ezibizayo. Isakhiwo esiphambili sigcinwa ngokusebenzisa izinto eziqinileyo kakhulu, ezifana neeceramics ze-silicon carbide kunye neeceramics ze-alumina njenge-lining yokuzinikela. Kwangaxeshanye, iiceramics ze-silicon carbide zinokunyamezela ukugugileka ixesha elide ngaphambi kokuba zifune ukutshintshwa, ubomi benkonzo ye-silicon carbide ceramic bubude obuphindwe ka-5 ukuya ku-7 kunezinto ze-alumina.

Iithayile zeCeramic zeSilicon Carbide eziKhuselekileyo kunye neePropati zeLining:

Ayinakhemikhali

Iyakhusela umbane

Ukukhukuliseka koomatshini kunye nokungagugi kakuhle

Ingatshintshwa

Iingenelo zeethayile kunye neeLinings ezimelana nokunxitywa yiCeramic:

Ingasetyenziswa apho kufuneka khona ukunyamezelana okuqinileyo okanye imiphetho emincinci

Ingasetyenziselwa ukuphinda iveze iindawo ezigugileyo ezikhoyo

Ingasetyenziswa ngeendlela ezininzi zokuncamathisela ezifana nokuwelda kunye nezincamathelisi

Yenzelwe ngokwezifiso izicelo ezithile

Ayinakumelana nokugqwala kakhulu

Isisombululo sokunciphisa ukuguguleka kancinci

Ikhusela iindawo ezihambayo ezichaphazeleka kakhulu ziimeko ezigugileyo

Ihlala ixesha elide kwaye isebenza ngcono kunezisombululo zokunciphisa ukuguguleka

Ubushushu obuphezulu kakhulu bokusetyenziswa ukuya kuthi ga kwi-1380°C

1. Ishishini lentsimbi

Inkqubo yokuhambisa: ivili lebhakethi iBai, idiski, ihopha iDu, isilo, i-apron yebhanti yokuhambisa, i-trolley tee, ihopha yokufumana

Inkqubo yokudibanisa: isisele sokuxuba, isilinda sokuxuba seDao esiphambili, isilinda sokuxuba sesibini, idiski yokuxuba, isigubhu sokuxuba, isikrapu, ipleyiti yepelletizing

Inkqubo yokusila: i-beneficiation hopper phantsi kwesikrini esingcangcazelayo, i-raw material transportation chute, i-cyclone dust collector kunye ne-pipeline, i-fan impeller

2. Ishishini lesamente:

Inkqubo yokutyumza ilitye le-limestone kunye nenkqubo yokuhluza i-homogenization eluhlaza kunye ne-fuel pre: i-chute, i-hopper, i-belt drum

Inkqubo yokugaya eluhlaza: i-vane yesikhokelo sokwahlulahlula, ikhowuni yokwahlulahlula, ityhubhu yokugaya ethe nkqo ukuya kwityhubhu yenkanyamba, inkanyamba, i-fuel mill (i-steel ball mill), i-separator housing, i-inner cone, i-pulverized cone pipe

Umatshini wokutshiza amafutha (intsimbi yokutshiza ibhola): indlu yokwahlulahlula, ikhowuni yangaphakathi, umbhobho wamalahle ocoliweyo, umbhobho wokubuyisela umgubo

3. Ishishini lezibuko

Ihopha elungisiweyo yebhedi, ihopha yomatshini wevili lebhakethi, ihopha elungisiweyo yesitishi sokudlulisa imithwalo yebhanti, ihopha yokukhupha impahla kwinqanawa

4. Ishishini lokunyibilikisa

Inkqubo yokuhambisa: i-head chute, i-silo (ibhini ephakathi, ibhini yomsila), umkhombe wesikrini oshukumayo, i-coke hopper, i-metering hopper

Inkqubo yokudibanisa: i-batching hopper, i-mixer ephambili (yesibini)

Inkqubo yokosa: ipompo yebhini enye, ityhubhu ye-calcine, i-batching hopper, i-ash hopper, i-intermediate bin hopper

5. Ishishini leekhemikhali:

Inkqubo yokuhambisa: i-hopper, i-silo

Inkqubo yokususa uthuli: umbhobho wokususa uthuli, ingqiniba, isingxobo sefeni kunye ne-impeller, isivunguvungu

6. Ishishini lamalahle:

Inkqubo yokuphatha amalahle: i-chute, i-hopper, i-silo

Inkqubo yokuhlamba amalahle: isivunguvungu esinoxinzelelo, isivunguvungu esiphakathi esingenaxinzelelo semveliso ezintathu, isivunguvungu esiphakathi esingenaxinzelelo semveliso ezine, iqela lesivunguvungu soxinzelelo

Inkqubo yokuhambisa: umbhobho, ingqiniba, umbhobho, i-hopper, i-silo, i-port yokusasazwa

7. Ishishini lemigodi:

I-Hydrocyclone, ii-spigots, i-apex, iipayipi, iingqiniba, ukugoba

Iiseramiki ezirhabaxa

Ukunganxibi Nxiba

Inkanyamba yoHlelo lweMigodi

I-PU edibeneyo

I-Polyurethane edibeneyo

Intsimbi Enemisonto Eqinileyo

I-ceramic engabonakaliyo

Ibhokisi yokukhusela ye-SISIC

Isingxobo sokukhusela se-RBSIC

Isixhobo sokutshisa iSilicon Carbide

Ityhubhu yeSilicon Carbide Nozzle

Izixhobo ze-E-Cigarette

Iiseramiki ezirhabaxa

Ifenitshala yeKiln

Ukumelana nobushushu obuphezulu

I-Reaction Bonded Silicon Carbide

Izixhobo zokukhusela emkhosini

Ukungabhobozi

Ukukhusela ukurhawuzelelwa

Iyamelana

Yenziwe ngentsimbi eshayinayo

Yenziwe eTshayina, iCeramics Compound Polyurethane, enganyangekiyo

I-China Compound PU

I-China Compound Polyurethane

I-Alumina Ceramic

Ityhubhu

Ityhubhu ye-Sic yobushushu obuphezulu ye-1650c

Yenziwe eTshayina i-Ceramic Composite PU engagugiyo

Iiceramics zeSilicon Carbide ezikumgangatho ophezulu

Indandatho yeCarbide yeSilicon ecocekileyo ephezulu

Iinxalenye zeCeramic zeSilicon Carbide ezingaqhelekanga

Izixhobo zobumba

Izixhobo zeCeramic zeSilicon Carbide

Izixhobo zodongwe

Yenziwe eTshayina Intsimbi Exineneyo YeCeramic Composite Sisic Lined Steel Engagugiyo

Icandelo leCeramic

Yenziwe eTshayina, iCeramic Composite Polyurethane eQinisekisiweyo ngokuGcina, enganyangekiyo

Ubunzima obuphezulu

I-92% ye-Alumina

Yenziwe eTshayina i-Industrial Wear-Resistant Ceramic Composite Polyurethane

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.