A cikin ɗaki mai tsabta na masana'antar semiconductor, ana sarrafa wafers baƙi masu haske da ƙarfe ɗaya bayan ɗaya; A cikin ɗakin ƙonewa na injin jirgin sama, wani ɓangaren yumbu na musamman yana fuskantar baftismar harshen wuta na 2000 ℃. A bayan waɗannan yanayin, akwai wani abu mai aiki da ake kira "dutse mai launin baƙi na masana'antu" -kayan yumbu na silicon carbide.

Wannan kayan mai ƙarfi, wanda ya fi lu'u-lu'u tauri, yana sake rubuta ƙa'idodin masana'antu masu inganci a hankali. Zai iya jure wa hasken wutar lantarki mai ƙarfi na na'urorin nukiliya, ya aika da makamashin lantarki mai ƙarfi na sabbin motocin makamashi cikin sauri, kuma ya zama babban kayan watsa zafi na tashoshin tushe na 5G. Amma a bayan irin wannan kyakkyawan aiki, akwai ƙalubalen da ba za a iya musantawa ba: yadda za a shawo kan wannan kayan "marasa tsari"?

Kayayyakin kayan suna ƙayyade ƙalubalen sarrafawa

Wahalar sarrafa silicon carbide kamar tsarin sassaka ne a kan gilashi. Taurinsa ya ninka na yumbu sau 3-5. Kayan aikin yankewa na al'ada suna kama da sassaka faranti na ƙarfe da alli, wanda ba wai kawai yana da ƙarancin inganci ba, har ma yana iya fasa saman da aka yi da injin. Abin da ya fi rikitarwa shi ne cewa wannan kayan yana da rauni a bayyane, kuma ƙaramin kuskure na iya karya shi kamar biskit, musamman ga sassan da suka yi daidai da kauri ƙasa da milimita 1, ana iya siffanta tsarin sarrafa shi da rawa a kan wayar ƙarfe.

Hanyar Ci Gaba ta Masana'antu ta Zamani

Bayan fuskantar waɗannan ƙalubalen, injiniyoyi sun ƙirƙiro manyan "hanyoyi guda uku na sarrafa kayan aiki":

1. Fasahar siffanta mold - wani tsari mai zafi kamar yin kek ɗin wata, wanda ke ba da damar foda silicon carbide ya "bi umarnin" a ƙarƙashin zafin jiki da matsin lamba mai yawa, wanda hakan ya sa ya dace musamman don ƙera kayan aikin yanke masana'antu na yau da kullun. Wannan fasaha kamar sanya maƙallan mold a kan kayan aiki ne, yana siffanta siffofi na yau da kullun a ƙarƙashin daidaitaccen tsarin zafin jiki.

2. Hanyar sassaka ruwa - ta amfani da fasahar ƙera allura, ana saka sinadarin a cikin miyar cakulan kamar mold, kuma ta hanyar sarrafa hanyar kwarara, ana siffanta gine-gine masu rikitarwa. Wannan hanyar tana ba da damar ƙera bututun ƙarfe marasa tsari don masu tura tauraron ɗan adam.

3. Fasahar sake gina foda - amfani da fasahar ƙarfe ta foda don sake gina ƙananan tsarin kayan aiki kamar tubalan gini, ƙirƙirar hatimin nukiliya wanda ke haɗa ƙarfi da daidaito. Wannan tsari yana ba da damar kayan aiki su fuskanci "canji" a matakin ƙwayoyin halitta, don cimma ci gaba mai ma'ana a cikin aiki.

Muhimman bayanai game da injinan daidaito

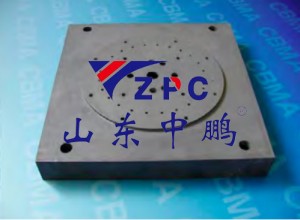

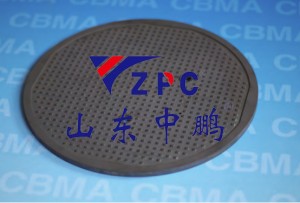

Domin a ƙware wannan kayan aiki, ba wai kawai ana buƙatar kayan aiki na zamani ba, har ma ana buƙatar ƙa'idodi uku na zinariya: ƙirar ƙira mai kyau, sa ido kan tsari mai kyau, da kuma tsauraran matakai kafin a yi amfani da kayan. Shandong Zhongpeng yana bin waɗannan ƙa'idodi uku a cikin tsarin samarwa, yana ƙoƙarin tabbatar da inganci da adadi. Ba wai kawai yana buƙatar ƙaruwar ƙimar samfurin da aka gama ba, har ma yana buƙatar cewa kayayyakin da aka gama su cika buƙatun abokan ciniki sosai.

A halin yanzu, tare da amfani da sabbin fasahohi kamar sarrafa laser da yankewa ta hanyar amfani da ultrasonic, yumburan silicon carbide suna karya shingen sarrafawa na ƙarshe. Waɗannan ci gaban ba wai kawai suna ba da damar "dutse masu launin baƙi" su koma ga masana'antu ba, har ma suna nuna isowar sabon zagaye na juyin juya halin kayan aiki.

Ga kamfanonin masana'antu da ke neman ci gaban fasaha, sarrafa silicon carbide ƙalubale ne kuma dama ce. Zaɓar abokan hulɗa na sarrafawa waɗanda ke da ƙwarewa mai zurfi da hanyoyin kirkire-kirkire zai zama mabuɗin zinare don buɗe ƙofar masana'antu masu inganci. Wannan kayan, wanda a da ake ɗaukarsa a matsayin 'ƙanƙantar sarrafawa', yana jiran ƙarin jarumai su gano babban sirrinsa.

Lokacin Saƙo: Afrilu-07-2025