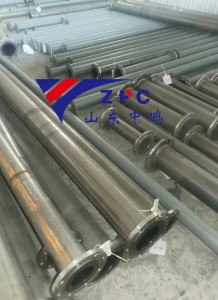

Esimweni sezimboni lapho izinga lokushisa eliphezulu, ukugqwala, kanye nokuguguleka kuhambisana khona, inkinga yokushintshwa njalo kwamapayipi ensimbi endabuko iyaqedwa yipayipi elisha lezinto ezibonakalayo –amapayipi amelana nokuguguleka kwe-silicon carbide, ngezakhiwo zazo eziyingqayizivele zezinto ezibonakalayo, kubangele inguquko kwezobuchwepheshe ohlelweni lokudlulisa amandla emkhakheni wezimboni.

1, ukusebenza Okuvelele okungaphezu kwemingcele yezinto zendabuko

Amapayipi amelana nokuguguleka kwe-silicon carbide abonise imingcele yokusebenza emangalisayo ekuqinisekisweni kwelabhorethri: ubulukhuni be-Vickers obungu-2800HV bungamelana nokuguguleka okuqhubekayo okuvela esihlabathini sedayimane, futhi ezimweni zokuthuthwa kwempuphu yamalahle ezitshalweni zamandla ezishisayo, impilo yawo yokusebenza icishe ibe yinde ngokuphindwe ka-15 kunamapayipi e-alloy endabuko.

Ekuhlolweni kwesimo sezulu esishisayo kakhulu, amapayipi e-silicon carbide agcina ubuqotho besakhiwo ekushiseni okuphezulu okungu-1350 ℃, kanti i-coefficient yokwandisa ukushisa iyingxenye eyodwa kwezintathu kuphela kuneyensimbi engagqwali. Ngokusho kwamacala okusetshenziswa, ekuthuthweni okuqhubekayo kwezinhlayiya zensimbi ezishisa kakhulu, ipayipi ibilokhu isebenza amahora angu-8000 ngaphandle kokuguquka noma ukuqhekeka.

Ukuphendula inselele enkulu yokugqwala embonini yamakhemikhali, izinto ze-silicon carbide zisebenza kahle kakhulu ku-sulfuric acid egxilile. Idatha ikhombisa ukuthi ngaphansi kwezimo ezifanayo zokusebenza, impilo yesevisi yamapayipi e-silicon carbide iphindwe izikhathi ezingu-8.2 kuneyamapayipi e-titanium alloy.

2, impumelelo kwezobuchwepheshe kwizicelo zemboni ehlukahlukene

Emgqeni wokukhiqizwa kwezinto zokwakha i-electrode ezinhle zamabhethri e-lithium, amapayipi aqondile e-silicon carbide axazulula inkinga yokuhamba enqubweni yokubala ukushisa okuphezulu. Izici zayo ezilula zithuthukisa kakhulu ukusebenza kahle kokufakwa, kuhlanganiswe nomklamo okhethekile wokuhambisa, okuqeda ngempumelelo izingozi zikagesi ongashintshi enqubweni yokukhiqiza.

Ukusetshenziswa emkhakheni wezimayini kuyimpumelelo enkulu: Ngemva kokuba isitshalo sokukhiqiza i-ore yethusi samukele amapayipi e-silicon carbide ahlanganisiwe, umjikelezo wokugcinwa kohlelo lokuhambisa udaka wandiswa kakhulu, okwasindisa kakhulu izindleko zokugcinwa.

3, ukuvela okuqhubekayo kwezinqubo zokukhiqiza ngokunemba

Ipayipi elihlanganisiwe elingamamitha amabili elenziwe kusetshenziswa ubuchwepheshe bokuncibilikisa ukusabela lidlula imikhawulo yosayizi wezingxenye ze-ceramic zendabuko. Ngokusebenzisa ukulawulwa kwenqubo yokuncibilikisa ukwakheka kwe-gradient, izinga lokucubungula ngokunemba kwephutha lokujiya kodonga lwepayipi liyancishiswa.

Njengamanje, sisekelwe ekubambisaneni kwebhizinisi lesikole kanye nokubambisana namanyuvesi aphezulu ukuthuthukisa imikhiqizo ye-silicon carbide ceramic esezingeni eliphezulu ehlangabezana kangcono nezidingo ezahlukahlukene zabasebenzisi, kufaka phakathi amapayipi angagugi e-silicon carbide.

Esikhathini esisha sezimboni, amapayipi angagugi e-silicon carbide awaseyona nje ikhambi lokufaka esikhundleni sezinto ezibonakalayo, kodwa ayisici esibalulekile esiqhuba ukuthuthukiswa okuhlakaniphile kwezimboni zezinqubo. Uguquko lwezinto ezibonakalayo, kusukela ekuthuthweni kwezinto ezibonakalayo zezimboni ezihlakaniphile kuya ezingxenyeni eziyinhloko zemishini yamandla amasha, luchaza kabusha amazinga okuthembeka okudluliselwa kwezimboni. Siyaqhubeka nokuhlakulela ukusungula izinto ezintsha futhi sizibophezele ekuhlinzekeni ngezixazululo ezenziwe ngokwezifiso zezimboni ezahlukahlukene, sisiza amakhasimende akhe izinhlelo zokukhiqiza ezisebenza kahle nezisimeme.

Uma nawe unentshisekelo ngemikhiqizo yethu, sicela uvakashele ku-[Shandong ZhongpengUkuze uthole imininingwane eyengeziwe yomkhiqizo, noma ushayele ucingo ku-(+86)15254687377 ukuze wenze i-aphoyintimenti yokuxilonga ukusetshenziswa kahle kwamandla emgqeni wokukhiqiza - asisebenzeni ndawonye, sifeze ukubambisana okuzuzisa wonke umuntu, futhi siqale isahluko esisha emkhakheni wezimboni.

Isikhathi sokuthunyelwe: Ephreli-01-2025