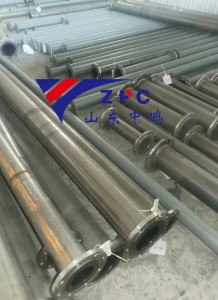

A fannin masana'antu inda yanayin zafi mai yawa, tsatsa, da lalacewa ke kasancewa tare, matsalar sauya bututun ƙarfe na gargajiya akai-akai na fuskantar matsala ta hanyar sabon bututun mai -bututun da ke jure lalacewa ta hanyar silicon carbide, tare da keɓantattun kayansu na musamman, sun haifar da juyin juya halin fasaha a cikin tsarin watsawa a fagen masana'antu.

1, Fitaccen aiki fiye da iyakokin kayan gargajiya

Bututun da ke jure wa lalacewa ta silicon carbide sun nuna ma'auni masu ban mamaki a cikin ingancin dakin gwaje-gwaje: taurin Vickers na 2800HV zai iya jure ci gaba da zaizayar ƙasa daga yashi mai lu'u-lu'u, kuma a cikin yanayin jigilar foda na kwal a cikin tashoshin wutar lantarki na zafi, tsawon lokacin aikinsu ya kusan sau 15 fiye da bututun ƙarfe na gargajiya.

A cikin gwajin yanayin zafi mai tsanani, bututun silicon carbide suna kiyaye ingancin tsarin a zafin jiki mai girma na 1350 ℃, tare da ma'aunin faɗaɗa zafi na kashi ɗaya bisa uku kawai na bakin karfe. A cewar sharuɗɗan amfani, a cikin ci gaba da jigilar ƙwayoyin ƙarfe masu zafi, bututun yana aiki akai-akai na tsawon awanni 8000 ba tare da lalacewa ko fashewa ba.

Dangane da ƙalubalen tsatsa mai ƙarfi a masana'antar sinadarai, kayan silicon carbide suna aiki sosai a cikin sinadarin sulfuric acid mai ƙarfi. Bayanai sun nuna cewa a ƙarƙashin irin wannan yanayin aiki, tsawon rayuwar bututun silicon carbide ya ninka na bututun titanium sau 8.2.

2, Ci gaban fasaha a aikace-aikacen masana'antu daban-daban

A cikin layin samar da kayan lantarki masu kyau don batirin lithium, bututun silicon carbide madaidaiciya suna magance matsalar sufuri a cikin tsarin calcination mai zafi. Halayensa masu sauƙi suna inganta ingantaccen shigarwa sosai, tare da ƙira na musamman mai sarrafa wutar lantarki, wanda ya yi nasarar kawar da haɗarin wutar lantarki mai tsauri a cikin tsarin samarwa.

Amfani da shi a fannin haƙar ma'adinai ya fi samun ci gaba: Bayan da kamfanin samar da ma'adinan tagulla ya ɗauki bututun haɗakar silicon carbide, an faɗaɗa tsarin kula da tsarin jigilar slurry sosai, wanda hakan ya ceci kuɗaɗen gyara sosai.

3, Ci gaba da juyin halitta na daidaici masana'antu hanyoyin

Bututun da aka ƙera mai tsawon mita 2 ta amfani da fasahar haɗa sinadarai yana karya iyakokin girman sassan yumbu na gargajiya. Ta hanyar sarrafa tsarin haɗa sinadarai na gradient, ana rage kuskuren daidaiton matakin injinan bututun mai na kauri bango.

A halin yanzu, mun dogara ne akan haɗin gwiwar kamfanoni na makaranta da kuma haɗin gwiwa da manyan jami'o'i don haɓaka samfuran yumbu na silicon carbide masu inganci waɗanda suka fi dacewa da buƙatu daban-daban na masu amfani, gami da bututun da ke jure lalacewa ta silicon carbide.

A sabon zamanin masana'antu, bututun da ke jure wa lalacewa ta silicon carbide ba wai kawai mafita ce ta maye gurbin kayan ba, amma muhimmin sashi ne da ke haifar da haɓaka masana'antun sarrafawa cikin hikima. Juyin juya halin kayan aiki, daga jigilar kayayyaki na masana'antu masu wayo zuwa manyan sassan sabbin kayan aikin makamashi, yana sake bayyana ma'aunin aminci na watsawa na masana'antu. Muna ci gaba da haɓaka sabbin kayan aiki kuma muna da niyyar samar da mafita na musamman ga masana'antu daban-daban, tare da taimaka wa abokan ciniki su gina tsarin samarwa mafi inganci da dorewa.

Idan kuma kuna sha'awar kayayyakinmu, da fatan za ku ziyarci [Shandong Zhongpeng] don ƙarin cikakkun bayanai game da samfur, ko a kira (+86)15254687377 don yin alƙawari don gano ingancin makamashi a layin samarwa - bari mu yi aiki tare, cimma haɗin gwiwa mai cin nasara, da kuma fara sabon babi a fannin masana'antu.

Lokacin Saƙo: Afrilu-01-2025