Kwimeko yemizi-mveliso apho ubushushu obuphezulu, ukugqwala, kunye nokuguguleka kuhambelana khona, ingxaki yokutshintshwa rhoqo kwemibhobho yesinyithi yendabuko iyaphulwa ngumbhobho omtsha wezinto -imibhobho engagugiyo ye-silicon carbide, ngeempawu zazo ezikhethekileyo zezinto ezibonakalayo, ziye zabangela utshintsho olukhulu kwezobuchwepheshe kwinkqubo yothumelo kwicandelo lemizi-mveliso.

1, ukusebenza okugqwesileyo ngaphaya kwemida yezixhobo zemveli

Iipayipi ezingagugiyo ze-silicon carbide zibonakalise iiparameter zokusebenza ezimangalisayo ekuqinisekisweni kwelebhu: ubunzima beVickers obuyi-2800HV bunokumelana nokukhukuliseka okuqhubekayo okuvela kwisanti yedayimani, kwaye kwiimeko zokuthutha umgubo wamalahle kwizityalo zamandla obushushu, ubomi bazo benkonzo bubude phantse ngokuphindwe ka-15 kuneepayipi ze-alloy zemveli.

Kwiimeko zovavanyo lobushushu obuphezulu, iipayipi ze-silicon carbide zigcina ukuqina kwesakhiwo kubushushu obuphezulu be-1350 ℃, kwaye i-thermal expansion coefficient ithatha isithathu kuneyentsimbi engagqwaliyo. Ngokweemeko zokusetyenziswa, ekuthuthweni okuqhubekayo kwamasuntswana esinyithi anobushushu obuphezulu, umbhobho ubusebenza ngokuqhubekayo kangangeeyure ezingama-8000 ngaphandle kokuguquka okanye ukuqhekeka.

Ukuphendula kumngeni omkhulu wokugqwala kwishishini leekhemikhali, izinto ze-silicon carbide zisebenza kakuhle kakhulu kwi-sulfuric acid exineneyo. Idatha ibonisa ukuba phantsi kweemeko ezifanayo zokusebenza, ubomi benkonzo yeepayipi ze-silicon carbide buphindwe ka-8.2 kunobo beepayipi ze-titanium alloy.

2, impumelelo yezobuchwepheshe kwizicelo zemizi-mveliso eyahlukeneyo

Kumgca wemveliso yezinto ze-electrode ezilungileyo zeebhetri ze-lithium, iipayipi ze-silicon carbide ezithe tye zisombulula ingxaki yokuthutha kwinkqubo yokubala ngobushushu obuphezulu. Iimpawu zayo ezikhaphukhaphu ziphucula kakhulu ukusebenza kakuhle kofakelo, kunye noyilo olukhethekileyo lokuhambisa, zisusa ngempumelelo iingozi zombane ongashukumiyo kwinkqubo yemveliso.

Ukusetyenziswa kwemigodi kuyimpumelelo enkulu: Emva kokuba isityalo sokuvelisa i-copper ore samkele imibhobho ye-silicon carbide edibeneyo, umjikelo wokugcinwa kwenkqubo yokuhambisa udaka wandiswa kakhulu, nto leyo eyasindisa kakhulu iindleko zokugcinwa.

3, uphuhliso oluqhubekayo lweenkqubo zokuvelisa ngokuchanekileyo

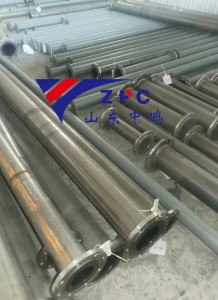

Umbhobho odibeneyo we-2-meter owenziwe ngetekhnoloji yokusinyisa i-reaction uphula umda wobukhulu beendawo ze-ceramic zemveli. Ngokusebenzisa ulawulo lwenkqubo yokusinyisa i-gradient, inqanaba lomatshini wokuchaneka kwempazamo yobukhulu bodonga lombhobho liyancitshiswa.

Okwangoku, sisekelwe kwintsebenziswano yeshishini lesikolo kunye nokusebenzisana neeyunivesithi eziphambili ukuphuhlisa iimveliso zeseramikhi ze-silicon carbide ezikumgangatho ophezulu ezihlangabezana ngcono neemfuno ezahlukeneyo zabasebenzisi, kubandakanya imibhobho engagugiyo ye-silicon carbide.

Kwixesha elitsha lemizi-mveliso, iipayipi ezingagugiyo ze-silicon carbide aziseyosisombululo sokutshintsha izinto nje kuphela, kodwa ziyinxalenye ephambili eqhuba ukuphuculwa okukrelekrele kwamashishini enkqubo. Uguquko lwezinto ezibonakalayo, ukusuka ekuthuthweni kwezinto zeefektri ezikrelekrele ukuya kwizinto eziphambili zezixhobo zamandla amatsha, luchaza ngokutsha imigangatho yokuthembeka yokudluliselwa kwezinto zoshishino. Siyaqhubeka nokuphuhlisa izinto ezintsha kwaye sizimisele ukubonelela ngezisombululo ezenzelwe wena kumashishini ahlukeneyo, sincede abathengi bakhe iinkqubo zemveliso ezisebenzayo nezizinzileyo.

Ukuba unomdla nakwiimveliso zethu, nceda undwendwele [Shandong ZhongpengUkuze ufumane iinkcukacha ezithe vetshe ngemveliso, okanye utsalele umnxeba ku-(+86)15254687377 ukuze wenze idinga lokuxilonga ukonga amandla kumgca wemveliso – masisebenzisane, sifezekise intsebenziswano phakathi kwamaqela omabini, size siqalise isahluko esitsha kwicandelo lemizi-mveliso.

Ixesha lokuthumela: Epreli-01-2025