Umbhobho onganyangekiyo ogqunywe nge-silicon carbide ceramic kunye ne-hydrocyclone kwizityalo zamandla

Iinkqubo zeMibhobho yeSilicon Carbide Ceramic: Ukuhlaziya iziseko zophuhliso zeZitishi zoMbane

Izakhiwo zokuvelisa umbane zijongene nemingeni enzima yokusebenza, apho iinkqubo zombhobho zihlala zisebenza:

- Ukujikeleza kobushushu okuqhubekayo (100–650°C)

- Isantya seenxalenye ezirhabaxa esidlula i-30 m/s

- Utshintsho lwe-pH ukusuka kwi-2–12 kwii-flue gas scrubbers

- Ukutshintshatshintsha koxinzelelo olujikelezayo (0–6 MPa)

Iipayipi zemveli zesinyithi kunye ne-polymer zihlala zisilela phantsi kwezi meko, nto leyo eyenza iipayipi ze-silicon carbide (SiC) ceramic ezingagugiyo zibe sisisombululo esenziwe ngobunjineli kwizityalo zamandla zanamhlanje.

Uphuhliso lweSayensi yezinto eziphathekayo

Iipayipi ze-ceramic ze-SiC zidibanisa iipropati ezizodwa ezibalulekileyo kwizicelo zecandelo lamandla:

- Ubunzima beVickers 28 GPa (4× nzima kune-tungsten carbide)

- Izinga lokunxiba <0.1 mm³/N·m (ASTM G65)

- Ukuqhuba Ubushushu 120 W/m·K (ngaphezulu kwentsimbi engagqwaliyo)

- Ukungasebenzi kakuhle kweekhemikhali (kumelana ne-98% H₂SO₄ kwi-300°C)

Iingenelo Zokusebenza Kwiinkqubo Ezibalulekileyo

1. Ukuphathwa kwamalahle kunye nokuThuthwa koMlotha

- Imelana nokuguguleka okukhukulisayo okungu-5–7 mm/ngonyaka ukusuka kwi-60% yodaka oluqinileyo

- Gcina ukuncipha kokuhamba kwamanzi okungaphantsi kwe-5% ngaphezulu kweeyure zokusebenza ezili-10,000

2. Ukususwa kwegesi kwiFlue (FGD)

- Ukusebenza okuchasene ne-pH kwiisekethe ze-limestone slurry

- Ukuphelisa ukubola kwemingxuma okubangelwa yikloridi

3. Ukuhanjiswa kothuthu lweempukane

- Uburhabaxa bomphezulu obuyi-0.08 μm kunciphisa ukunamathelana kwamasuntswana

- Phatha umthamo we-50 tph kwii-engile zokuthambekela ezingama-35°

Utshintsho lwezoqoqosho

Abaqhubi bezityalo baxela iingenelo ezinokulinganiswa:

- Ukunciphisa ngama-70% ukutshintshwa kwemibhobho okungacwangciswanga

- Iindleko zomsebenzi zokugcina eziphantsi ngama-55%

- I-18% iphucule ukusebenza kakuhle kobushushu kwimijikelo yomphunga

- 40% ixesha elide lenkqubo xa kuthelekiswa nezinye iindlela ze-alloy

Ukufakelwa kunye nokuguquguquka kokusebenza

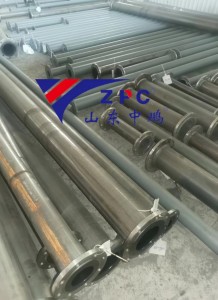

- Amacandelo e-Modular 1–6 m anee-flanged/threaded connections

- Ukunciphisa ubunzima ngama-60% xa kuthelekiswa nezinto ezilingana nentsimbi (3.2 g/cm³ density)

- Ingafakwa kwakhona kwiinkxaso zepayipi ezikhoyo kunye nee-hangers

- Iyahambelana neenkqubo zokujonga ezikrelekrele zokuqikelela ukunxiba

Izinto Ezintsha Ezijolise Kwixesha Elizayo

Izisombululo zemibhobho zeSiC zesizukulwana esilandelayo ziyadibanisa:

- I-Gradient porosity yokunciphisa uxinzelelo lobushushu

- Iindidi eziqhubayo zemvula ye-electrostatic

- Amalunga e-ceramic-elastomer e-hybrid okunciphisa ukungcangcazela

- Ukuzicoca okuncinci komphezulu

Ukususela kwizityalo ezisebenzisa amalahle ukuya kwizixhobo ezisebenzisa inkunkuma ukuya kumandla, iipayipi ze-silicon carbide ceramic zichaza ngokutsha ukuthembeka kweziseko zophuhliso lwamandla. Indibaniselwano yazo eyahlukileyo yokuqina koomatshini, ukunyamezela ubushushu, kunye nokuzinza kweekhemikhali kuqinisekisa ukusebenza okuqhubekayo phantsi kweemeko ezinzima - ukuguqula iishedyuli zolondolozo ukusuka ekulungisweni okusabelayo ukuya ekuphuculweni okucwangcisiweyo, okungabizi kakhulu.

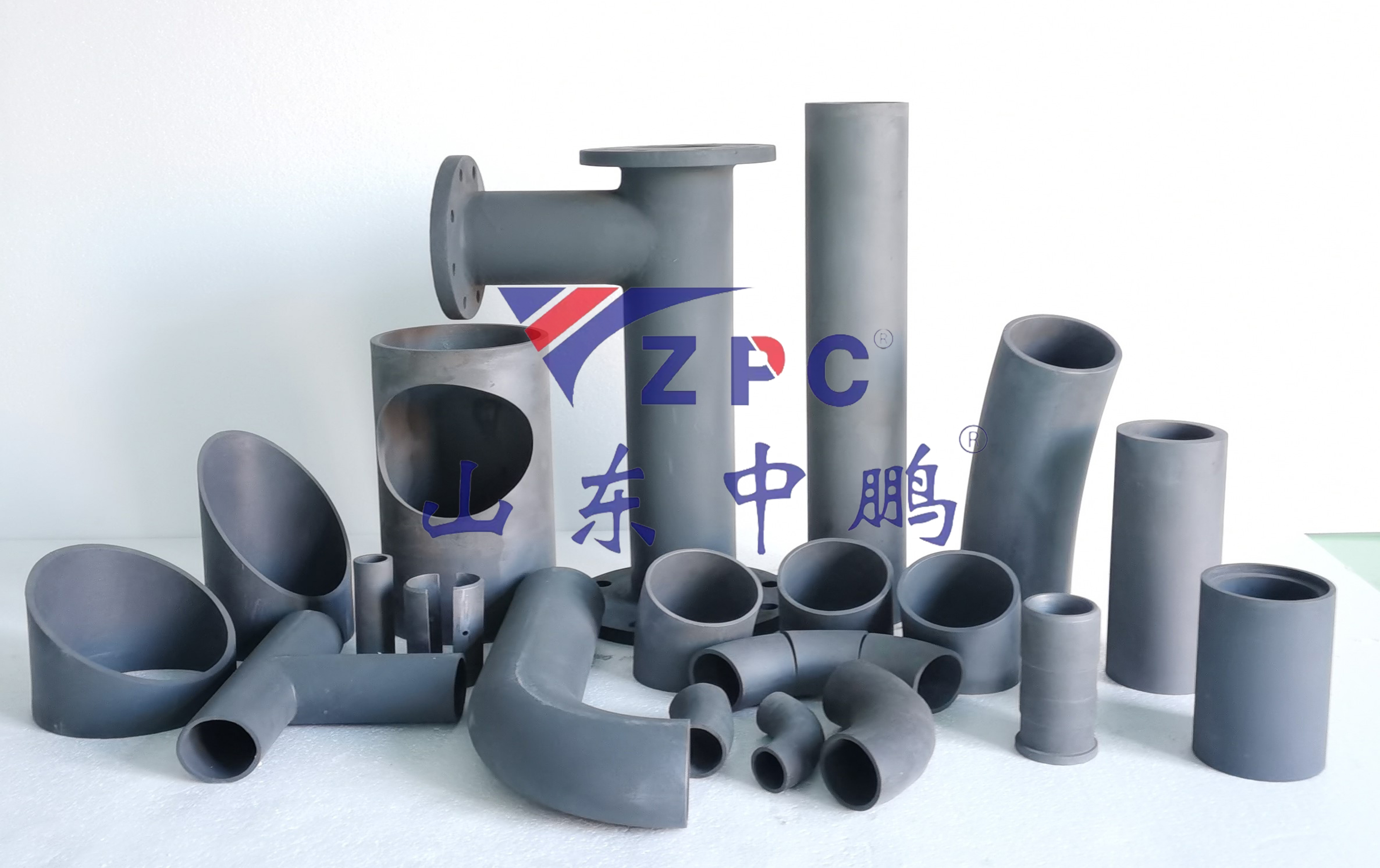

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.