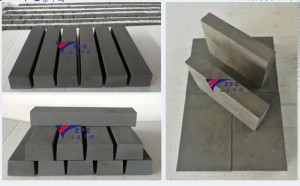

Iithayile zeCeramic zeRBSC Silicon Carbide

Iithayile zeCeramic zeRBSC Silicon CarbideZivele njengesisombululo esiphambili sokulwa nokuguga nokugqwala kwiindawo zoshishino ezifuna amandla. Ezi thayile zeseramikhi kunye nee-linings ezenziwe ngobunjineli zibonelela ngokusebenza okungenakuthelekiswa nanto kwiinkqubo zokuphatha izinto, zandisa ubomi bezixhobo ngelixa ziphucula ukusebenza kakuhle kwiinkqubo ezibalulekileyo.

Ubuchule boBunjineli

Izixhobo zethu ze-silicon carbide (SiC) ezenziwe ngokuchanekileyo zigqwesile ngeempawu zazo ezikhethekileyo:

- Ubunzima beMohs 9.5 (13 kwisikali esihlaziyiweyo) ukuze kuthintelwe ukuguguleka kakhulu

- Ukuqina kokuqhekeka okukhulu kwe-4–5× xa kuthelekiswa nezinye iindlela ze-SiC ezibotshelelwe yi-nitride

- Ubomi benkonzo obude kangange-5–7× xa kuthelekiswa nee-linings ze-alumina zemveli

- Ukungasebenzi kakuhle kweekhemikhali ngokuchasene nee-asidi, ii-alkali, kunye nezinyibilikisi ze-organic (pH 0–14)

- Uzinzo lobushushu olugcina ukuthembeka ukusuka kwi -60°C ukuya kwi-1650°C

Izisombululo zoKhuseleko ezenzelwe wena

Ifumaneka ngobukhulu obuphakathi kwe-8–45 mm, ii-linings zethu ze-ceramic ziyahambelana neemfuno ezahlukeneyo zokusebenza:

- Uqwalaselo olungenampembelelo kwiichute kunye neehoppers

- Iindawo ezingasebenzi kakuhle kwiinkqubo zokuhambisa

- Amanqanaba aphezulu okucoceka kokutya/amayeza

- Iindidi zokukhusela ngombane kwiindawo eziqhumayo

Izicelo eziqhutywa kukusebenza

1. Iinkqubo zokuphatha izinto

- Imibhobho yodaka enokukhukuliseka okuncitshisiweyo ngama-90%

- Iitrommel zemigodi ezinemijikelo yenkonzo ende eyi-3×

- Iinkanyamba zesityalo sesamente ezisinde iiyure zokusebenza ezingaphezu kwama-50,000

2. Izixhobo Zokucubungula

- Iilinki ze-pulverizer zamalahle ezimelana nefuthe lamasuntswana angama-120 m/s

- Iinqanawa ze-reactor zekhemikhali eziphatha imidiya ebolileyo

- Iipayipi zesityalo sentsimbi ezimelana nothuthu olurhabaxa oluphuma kwiimpukane

3. Izinto ezikhethekileyo

- Iingubo ze-Rotor blade zezahluli ze-centrifugal

- Nxiba iipleyiti zokucubungula i-biomass

- Izinto ezifakwe ngendlela eyenzelwe wena zejometri ezintsonkothileyo

Impembelelo yoQoqosho

Utshintsho oluya kwi-silicon carbide linings lubonisa iingenelo ezinokulinganiswa:

- Ukuncipha kwama-60–80% kwixesha lokungasebenzi elingacwangciswanga

- Iindleko zokugcina ubomi bonke eziphantsi ngama-45%

- Ukonga amandla ngama-30% ngokusebenzisa ukuhamba kwezinto ezilungiselelweyo

- Ukusebenziseka kwakhona kwe-90% kwezinto ezigugileyo

Ukufakwa kunye nokuguquguquka

Yenzelwe ukuhlanganiswa okungenamthungo:

- Iinkqubo zeethayile zeModular ezineedizayini ezidibeneyo

- Ukulungiswa kwe-epoxy enamandla aphezulu okanye oomatshini

- Iinkonzo zokulungisa nokulungisa izinto kwindawo yokusebenza

- Ukuhambelana kokujonga ukunxiba ngexesha langempela

Izinto Ezintsha Ezilungele Ikamva

Iinwele ze-silicon carbide zesizukulwana esilandelayo ziquka:

- Izakhiwo zoxinano lwe-gradient zokufunxa impembelelo

- Unyango lokuzithambisa umphezulu oluzisebenzisa ngokwalo

- Ukulandelela ukunxiba okunikwe amandla yi-RFID

- Iinkqubo ze-hybrid ceramic-metal ezidityanisiweyo

Ukususela kwimisebenzi yemigodi ukuya kwizityalo zokucubungula iikhemikhali, ii-linings ze-silicon carbide ceramic zimele umgangatho omtsha wokukhusela ukuguguleka kwemizi-mveliso. Indibaniselwano yazo eyahlukileyo yokuqina koomatshini, uzinzo lweekhemikhali, kunye nokunyamezela kobushushu iguqula ukusebenza kwezixhobo - kunciphisa iindleko zomjikelo wobomi ngelixa iphucula ukuthembeka kwemveliso kwiindawo zokusebenza ezirhabaxa kakhulu kwihlabathi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.