Cov yeeb nkab uas tiv taus kev hnav thiab hydrocyclone uas muaj silicon carbide ceramic lined hauv cov chaw tsim hluav taws xob

Cov Txheej Txheem Yeeb Nkab Silicon Carbide: Kev Tsim Kho Dua Tshiab ntawm Cov Chaw Tsim Hluav Taws Xob

Cov chaw tsim hluav taws xob ntsib teeb meem loj heev rau kev ua haujlwm, nrog rau cov kav dej uas siv tau ntev:

- Kev kub hnyiab tas mus li (100–650 ° C)

- Cov khoom tawg uas nrawm tshaj 30 m/s

- pH kev hloov pauv ntawm 2–12 hauv cov roj flue scrubbers

- Kev hloov pauv ntawm lub zog siab (0–6 MPa)

Cov kav dej hlau thiab cov kav dej polymer ib txwm muaj feem ntau tsis ua haujlwm nyob rau hauv cov xwm txheej no, ua rau cov kav dej silicon carbide (SiC) ceramic hnav-resistant yog qhov kev daws teeb meem tsim rau cov chaw tsim hluav taws xob niaj hnub.

Kev Tshawb Fawb Txog Khoom Siv

Cov kav dej SiC ceramic muab cov khoom tshwj xeeb tseem ceeb rau kev siv hluav taws xob:

- Vickers Hardness 28 GPa (4 × nyuaj dua li tungsten carbide)

- Tus Nqi Hnav <0.1 mm³/N·m (ASTM G65)

- Kev Ua Kub Thermal 120 W/m·K (zoo dua li cov hlau tsis xeb)

- Kev Tsis Muaj Tshuaj Lom Zem (tiv taus 98% H₂SO₄ ntawm 300 ° C)

Cov Kev Zoo ntawm Kev Ua Haujlwm hauv Cov Txheej Txheem Tseem Ceeb

1. Kev Tswj Thee thiab Kev Thauj Cov Tshauv

- Tiv taus 5–7 hli/xyoo kev hnav los ntawm 60% cov khoom khov slurry

- Tswj kom txo qis dej ntws tsawg dua 5% dhau 10,000 teev ua haujlwm

2. Kev Tshem Tawm Cov Pa Hluav Taws Xob (FGD)

- Kev ua haujlwm tsis kam rau pH hauv cov voj voog limestone slurry

- Tshem tawm cov xeb uas ua rau muaj chloride

3. Kev Thauj Khoom Siv Hluav Taws Xob

- 0.08 μm qhov roughness ntawm qhov chaw txo qhov kev sib txuas ntawm cov khoom me me

- Tswj tau 50 tph ntawm 35 ° lub kaum sab xis

Kev Hloov Pauv Nyiaj Txiag

Cov neeg ua haujlwm cog qoob loo qhia txog cov txiaj ntsig ntsuas tau:

- Txo tau 70% ntawm kev hloov cov yeeb nkab uas tsis tau npaj tseg

- 55% txo cov nqi kho vaj tse

- 18% txhim kho kev ua haujlwm thermal hauv cov voj voog ua pa

- 40% ntev dua lub neej ntawm lub cev piv rau lwm cov hlau sib xyaw

Kev Yooj Yim Rau Kev Teeb Tsa & Kev Ua Haujlwm

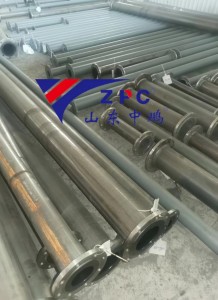

- Cov ntu modular 1–6 m nrog cov kev sib txuas flanged/threaded

- Txo qhov hnyav 60% piv rau cov hlau sib npaug (3.2 g/cm³ qhov ceev)

- Retrofittable rau cov yeeb nkab uas twb muaj lawm thiab cov hangers

- Sib xws nrog cov txheej txheem saib xyuas ntse rau kev kwv yees hnav

Kev Tsim Kho Tshiab Uas Tsom Mus Rau Yav Tom Ntej

Cov kev daws teeb meem SiC piping tiam tom ntej no suav nrog:

- Gradient porosity rau kev txo qhov kev ntxhov siab thermal

- Cov qauv sib txawv rau cov dej nag electrostatic

- Cov pob qij txha sib xyaw ua ke ntawm cov ceramic-elastomer rau kev txo kev co

- Cov qauv nano-nto uas ntxuav tau tus kheej

Txij li cov chaw tsim hluav taws xob uas siv thee mus rau cov chaw pov tseg ua hluav taws xob, cov kav dej ceramic silicon carbide txhais dua qhov kev ntseeg tau hauv cov chaw tsim hluav taws xob. Lawv qhov kev sib xyaw ua ke ntawm kev ua kom lub zog kho tshuab, kev ua kom sov, thiab kev ruaj khov ntawm cov tshuaj lom neeg ua kom muaj kev ua haujlwm tas mus li hauv qab qhov xwm txheej hnyav - hloov cov sijhawm txij nkawm los ntawm kev kho kom rov qab mus rau kev txhim kho uas tau npaj tseg, pheej yig.

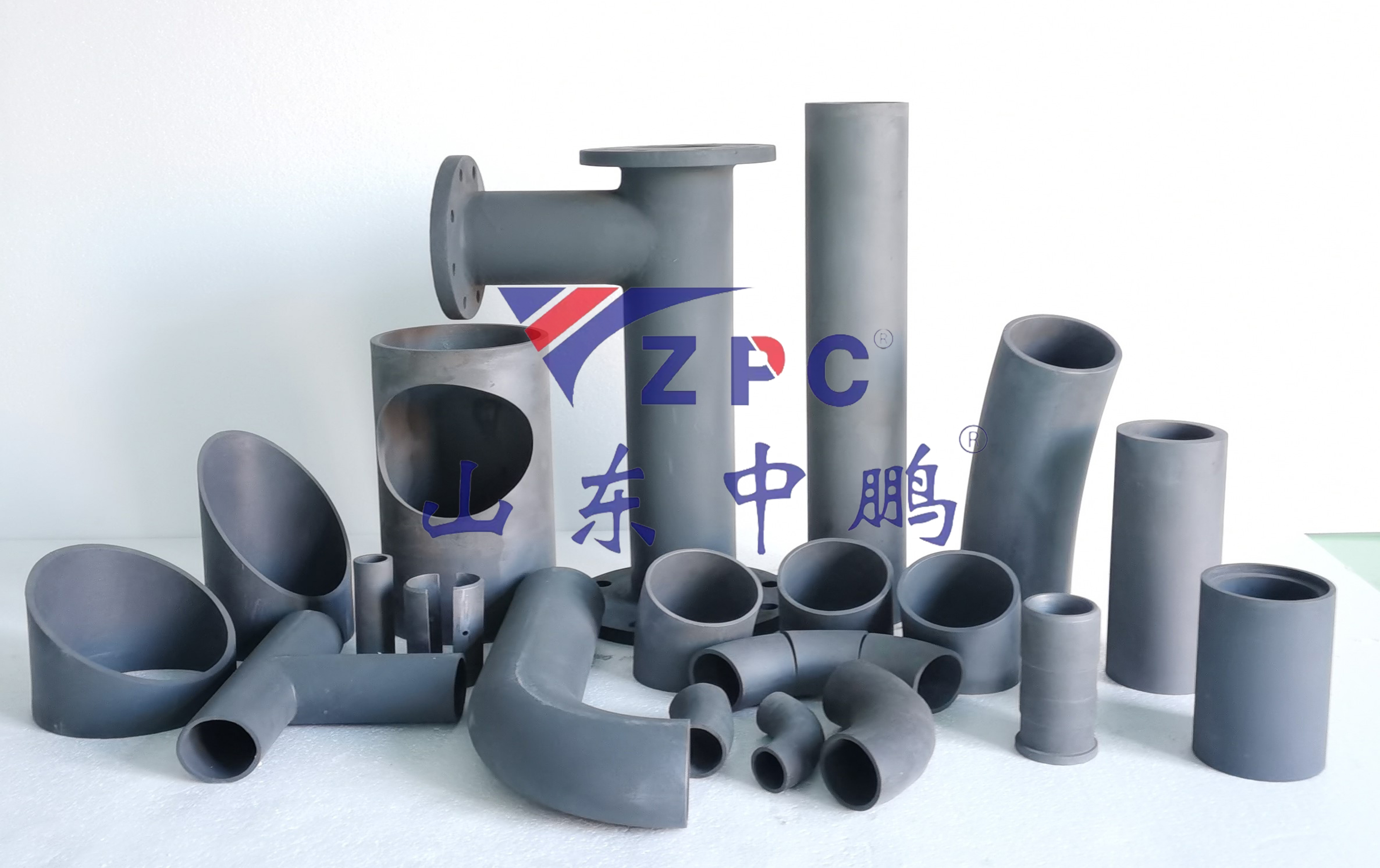

Shandong Zhongpeng Special Ceramics Co., Ltd yog ib qho ntawm cov khoom siv tshiab silicon carbide ceramic loj tshaj plaws hauv Suav teb. SiC technical ceramic: Moh qhov nyuaj yog 9 (New Moh qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. SiC cov khoom lub neej kev pabcuam yog 4 txog 5 zaug ntev dua li 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Cov txheej txheem hais nqe yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob rau tsis muaj leej twg. Peb ib txwm mob siab rau kev sib tw peb lub hom phiaj thiab muab peb lub siab rov qab rau lub zej zog.