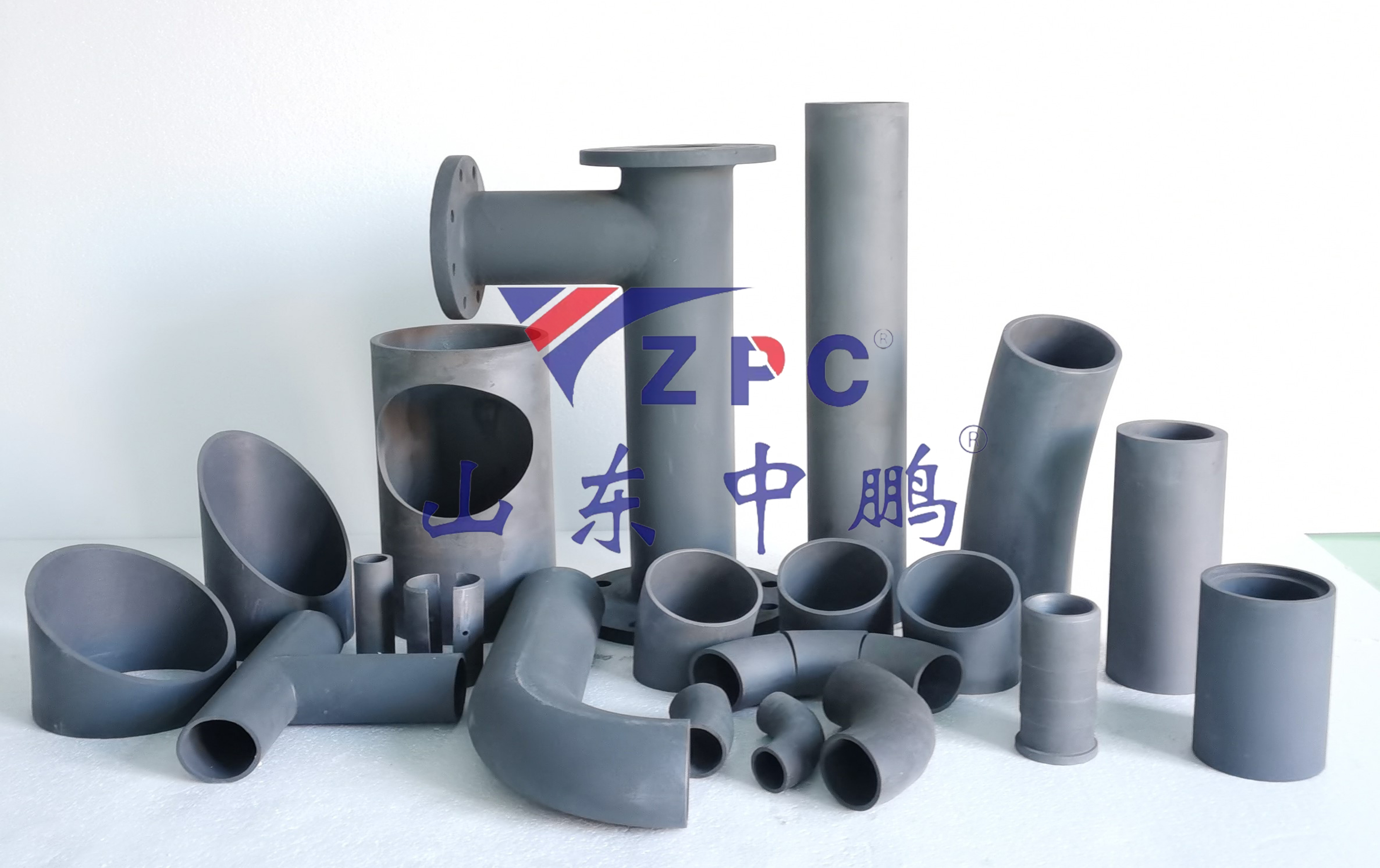

Bututun da ke jure lalacewa da kuma hydrocyclone a cikin tashoshin wutar lantarki na silicon carbide

Tsarin Bututun Silinda Carbide na Yumbu: Sake Kirkiro Kayayyakin Aikin Tashar Wutar Lantarki

Cibiyoyin samar da wutar lantarki suna fuskantar ƙalubale masu tsanani, inda tsarin bututun ke dawwama:

- Ci gaba da zagayowar zafi (100–650°C)

- Gudun barbashi masu abrasive fiye da m30/s

- bambancin pH daga 2-12 a cikin masu goge iskar gas

- Canjin matsin lamba mai zagaye (0-6 MPa)

Bututun ƙarfe na gargajiya da na polymer galibi suna lalacewa a ƙarƙashin waɗannan yanayi, wanda hakan ke sa bututun da ke jure lalacewa na silicon carbide (SiC) na yumbu su zama mafita ga tashoshin wutar lantarki na zamani.

Nasarar Kimiyyar Kayan Aiki

Bututun yumbu na SiC sun haɗa da kaddarorin musamman masu mahimmanci don aikace-aikacen ɓangaren makamashi:

- Taurin Vickers 28 GPa (4× ya fi ƙarfin tungsten carbide)

- Yawan lalacewa <0.1 mm³/N·m (ASTM G65)

- Matsakaicin kwararar zafi 120 W/m·K (ƙarfe ya fi na bakin ƙarfe kyau)

- Rashin Ingancin Sinadarai (yana jure wa 98% H₂SO₄ a zafin jiki na 300°C)

Fa'idodin Aiki a Tsarin Mahimmanci

1. Gudanar da Kwal da Sufurin Toka

- Yana jure lalacewa mai guba daga kashi 60% na sinadarin da ke cikinsa daga 5-7 mm/shekara

- Kiyaye raguwar kwararar ruwa sama da kashi 5% sama da sa'o'i 10,000 na aiki

2. Rufe Iskar Gas Mai Tsafta (FGD)

- Ayyukan da ke jure pH a cikin da'irar slurry na dutse

- Kawar da tsatsa da chlorine ke haifarwa a cikin bututun

3. Isarwa da Toka ta Tashi

- Tsananin saman 0.08 μm yana rage mannewar barbashi

- Rike ƙarfin tph 50 a kusurwar karkata 35°

Sauyin Tattalin Arziki

Masu aikin shuka sun ba da rahoton fa'idodi masu ma'ana:

- Rage kashi 70% na maye gurbin bututun da ba a tsara ba

- Rage farashin aikin gyara kashi 55%

- Ingantaccen ingancin zafi 18% a cikin zagayowar tururi

- Tsawaita tsawon rai na tsarin kashi 40% idan aka kwatanta da madadin ƙarfe

Shigarwa & Sauƙin Aiki

- Sassan zamani na mita 1–6 tare da haɗin da aka yi da flange/threaded

- Rage nauyi kashi 60% idan aka kwatanta da ƙarfe (3.2 g/cm³ yawa)

- Mai iya daidaitawa da tallafin bututun da ke akwai da kuma rataye su

- Mai jituwa tare da tsarin sa ido mai wayo don hasashen lalacewa

Sabbin Sabbin Abubuwa Masu Mayar da Hankali Kan Su Nan Gaba

Maganin bututun SiC na zamani sun haɗa:

- Porosity na gradient don rage damuwa ta zafi

- Bambance-bambancen sarrafawa don hazo na electrostatic

- Haɗin yumbu-elastomer masu haɗaka don damƙar girgiza

- Tsarin nano mai tsaftace kai

Daga masana'antun da ke amfani da kwal zuwa wuraren da ake amfani da sharar gida zuwa makamashi, bututun yumbu na silicon carbide suna sake fasalta aminci a cikin kayayyakin wutar lantarki. Haɗinsu na musamman na juriyar injina, juriyar zafi, da kwanciyar hankali na sinadarai yana tabbatar da ci gaba da aiki a ƙarƙashin mawuyacin yanayi - yana canza jadawalin kulawa daga gyare-gyare masu amsawa zuwa haɓakawa da aka tsara, masu inganci da araha.

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.