Chitoliro cholimba cha silicon carbide cholimba ndi hydrocyclone m'mafakitale opangira magetsi

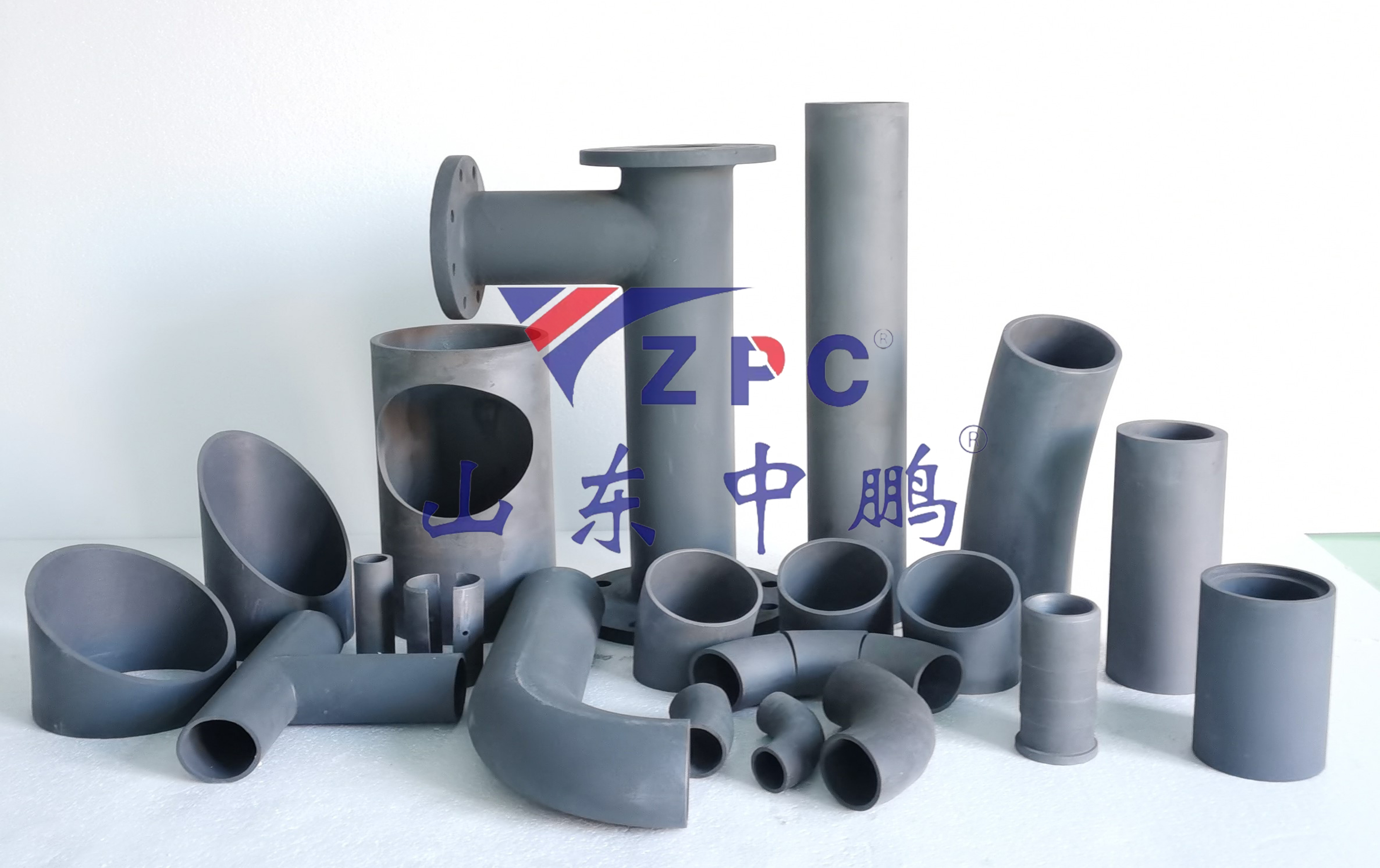

Makina Opopera a Silicon Carbide CeramicKukonzanso Zomangamanga za Magetsi

Malo opangira magetsi akukumana ndi mavuto aakulu pantchito, ndipo mapaipi amatha kugwira ntchito:

- Kutentha kosalekeza (100–650°C)

- Kuthamanga kwa tinthu tomwe timayamwa mopitirira 30 m/s

- Kusiyana kwa pH kuyambira 2–12 mu zotsukira mpweya wa flue

- Kusinthasintha kwa kuthamanga kwa mpweya (0–6 MPa)

Mapaipi achitsulo ndi a polima achikhalidwe nthawi zambiri amalephera pansi pa mikhalidwe imeneyi, zomwe zimapangitsa mapaipi osatha kutopa a silicon carbide (SiC) ceramic kukhala njira yopangidwira mafakitale amagetsi amakono.

Kupambana kwa Sayansi Yazinthu Zachilengedwe

Mapaipi a SiC ceramic amaphatikiza zinthu zapadera zofunika pakugwiritsa ntchito mphamvu:

- Vickers Hardness 28 GPa (4 × yolimba kuposa tungsten carbide)

- Kuchuluka kwa Kuvala <0.1 mm³/N·m (ASTM G65)

- Kutentha kwa 120 W/m·K (kwapamwamba kuposa chitsulo chosapanga dzimbiri)

- Kusagwira Ntchito kwa Mankhwala (kumalimbana ndi 98% H₂SO₄ pa 300°C)

Ubwino Wogwirira Ntchito mu Machitidwe Ofunika

1. Kusamalira Malasha ndi Kunyamula Phulusa

- Pitirizani kuwononga kwa 5–7 mm/chaka kuchokera ku matope olimba a 60%.

- Sungani kuchepa kwa madzi oyenda pansi pa <5% pa maola 10,000 ogwira ntchito

2. Kuchotsa Mpweya Woipa (FGD)

- Kugwira ntchito kosagonja kwa pH m'mabwalo a miyala yamchere

- Kuchotsa dzimbiri lochokera ku chloride

3. Kutumiza Phulusa la Ntchentche

- Kukhwima kwa pamwamba kwa 0.08 μm kumachepetsa kumatirira kwa tinthu tating'onoting'ono

- Gwiritsani ntchito mphamvu ya 50 tph pa ngodya zopendekera za 35°

Kusintha kwa Zachuma

Ogwira ntchito m'mafakitale amanena kuti ubwino wake ndi woyezeka:

- Kuchepetsa kwa 70% kwa kusintha mapaipi osakonzedwa

- 55% yotsika mtengo yokonza ntchito

- 18% yakhala ikugwira bwino ntchito ya kutentha mu nthunzi

- 40% nthawi yayitali ya dongosolo poyerekeza ndi njira zina za alloy

Kukhazikitsa & Kusinthasintha kwa Ntchito

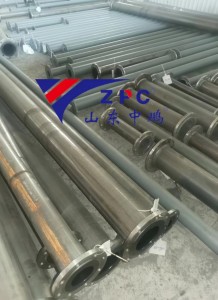

- Zigawo za modular 1–6 m zokhala ndi zolumikizira zopindika/zolukana

- Kuchepetsa kulemera kwa 60% poyerekeza ndi chitsulo chofanana nacho (kuchuluka kwa 3.2 g/cm³)

- Yokonzeka kusinthidwa ku zothandizira ndi zopachikira mapaipi zomwe zilipo kale

- Imagwirizana ndi njira zowunikira zanzeru zodziwira kuvala

Zatsopano Zoyang'ana M'tsogolo

Mayankho a mapaipi a SiC a m'badwo wotsatira akuphatikiza:

- Ma porosity a gradient ochepetsa kupsinjika kwa kutentha

- Mitundu yoyendetsera mpweya wamagetsi

- Ma hybrid ceramic-elastomer joints kuti achepetse kugwedezeka

- Zodziyeretsa zokha pamwamba

Kuyambira pa mafakitale opangidwa ndi malasha mpaka malo otayira zinthu kukhala magetsi, mapaipi a ceramic a silicon carbide amasintha kudalirika kwa zomangamanga zamagetsi. Kuphatikiza kwawo kwapadera kwa kulimba kwa makina, kupirira kutentha, komanso kukhazikika kwa mankhwala kumatsimikizira kuti ntchito yopitilira ikugwira ntchito pansi pa mikhalidwe yovuta kwambiri - kusintha nthawi yokonza kuchokera pakukonza mwachangu kupita ku kukonzanso kokonzedwa komanso kotsika mtengo.

Shandong Zhongpeng Special Ceramics Co., Ltd ndi imodzi mwa njira zazikulu kwambiri zothetsera zinthu zatsopano za silicon carbide ceramic ku China. SiC technical ceramic: Kuuma kwa Moh ndi 9 (Kuuma kwa New Moh ndi 13), komwe kumalimbana bwino ndi kukokoloka ndi dzimbiri, kukana bwino kwambiri - kukana komanso kukana okosijeni. Moyo wa ntchito wa SiC ndi wautali nthawi 4 mpaka 5 kuposa 92% alumina. MOR ya RBSiC ndi nthawi 5 mpaka 7 kuposa ya SNBSC, ingagwiritsidwe ntchito pazinthu zovuta kwambiri. Njira yowerengera mawu ndi yachangu, kutumiza kumakhala monga momwe kunalonjezera ndipo khalidwe lake ndi lapamwamba kwambiri. Nthawi zonse timapitilizabe kutsutsa zolinga zathu ndikubwezera mitima yathu kwa anthu.