Ipayipi elivikela ukuguguleka elinophahla lwe-silicon carbide kanye ne-hydrocyclone ezitshalweni zikagesi

Izinhlelo Zokubhoboza Ipayipi Le-Silicon Carbide Ceramic: Ukuvuselela Ingqalasizinda Yesikhungo Sikagesi

Izikhungo zokuphehla ugesi zibhekene nezinselele ezinkulu zokusebenza, kanti izinhlelo zamapayipi zihlala isikhathi eside:

- Ukujikeleza kokushisa okuqhubekayo (100–650°C)

- Ijubane lezinhlayiya ezikhukhumezayo elidlula ama-30 m/s

- Ukwehluka kwe-pH kusuka ku-2–12 kuma-flue gas scrubbers

- Ukuguquguquka kwengcindezi yokujikeleza (0–6 MPa)

Amapayipi endabuko ensimbi kanye ne-polymer avame ukwehluleka ngaphansi kwalezi zimo, okwenza amapayipi e-silicon carbide (SiC) ceramic amelana nokuguguleka abe yisisombululo esenziwe ngobunjiniyela sezitshalo zamandla zesimanje.

Ukuthuthuka Kwesayensi Yezinto Ezibonakalayo

Amapayipi e-ceramic e-SiC ahlanganisa izakhiwo ezihlukile ezibalulekile ekusetshenzisweni komkhakha wamandla:

- Ukuqina kwe-Vickers 28 GPa (4 × okunzima kune-tungsten carbide)

- Izinga Lokugqokwa <0.1 mm³/N·m (ASTM G65)

- Ukushisa Okuphezulu 120 W/m·K (okungcono kunensimbi engagqwali)

- Ukungasebenzi kahle kwamakhemikhali (kumelana no-98% H₂SO₄ ku-300°C)

Izinzuzo Zokusebenza Ezinhlelweni Ezibucayi

1. Ukuphathwa Kwamalahle Nokuthuthwa Komlotha

- Imelana nokuguguleka okugugulekayo okungu-5–7 mm/ngonyaka kusuka ku-slurry engu-60% yokuqukethwe okuqinile

- Gcina ukugeleza okungaphansi kuka-5% kuncishisiwe ngaphezu kwamahora okusebenza ayi-10,000

2. Ukususwa Kwegesi Ye-Flue (FGD)

- Ukusebenza okumelana ne-pH kumasekethe e-limestone slurry

- Susa ukugqwala kwemigodi okubangelwa yi-chloride

3. Ukuhanjiswa Komlotha Wempukane

- Ubulukhuni bomphezulu obungu-0.08 μm kunciphisa ukunamathela kwezinhlayiya

- Umthamo wokuphatha ongu-50 tph kuma-engeli angu-35° okuthambekela

Uguquko Lwezomnotho

Abaqhubi bezitshalo babika izinzuzo ezilinganisekayo:

- Ukwehla ngo-70% ekushintsheni kwamapayipi okungahleliwe

- Izindleko zomsebenzi zokulungisa eziphansi ngo-55%

- 18% ngcono ukusebenza kahle kokushisa emijikelezweni yesitimu

- Isikhathi sokuphila esinwetshiwe esingu-40% uma kuqhathaniswa nezinye izindlela ze-alloy

Ukufakwa Nokuguquguquka Kokusebenza

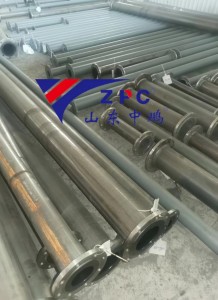

- Izingxenye ze-Modular ezingamamitha angu-1–6 ezinezixhumanisi ezigoqekile/ezinentambo

- Ukunciphisa isisindo ngo-60% uma kuqhathaniswa nokulingana kwensimbi (3.2 g/cm³ ukuminyana)

- Ingafakwa kabusha ezisekelweni zamapayipi neziphanyeko ezikhona

- Iyahambisana nezinhlelo zokuqapha ezihlakaniphile zokubikezela ukuguguleka

Izinto Ezintsha Ezigxile Esikhathini Esizayo

Izixazululo zepayipi le-SiC zesizukulwane esilandelayo zihlanganisa:

- I-Gradient porosity yokunciphisa ukucindezeleka kokushisa

- Izinhlobo eziqhubayo zemvula kagesi

- Amalunga e-ceramic-elastomer ahlanganisiwe okunciphisa ukudlidliza

- Ukuthungwa okungaphezulu okuzihlanzayo

Kusukela ezitshalweni ezisebenzisa amalahle kuya ezindaweni ezisebenzisa imfucuza kuya emandleni, amapayipi e-silicon carbide ceramic achaza kabusha ukuthembeka kwengqalasizinda yamandla. Inhlanganisela yawo eyingqayizivele yokuqina komshini, ukuqina kokushisa, kanye nokuqina kwamakhemikhali kuqinisekisa ukusebenza okuqhubekayo ngaphansi kwezimo ezimbi kakhulu - okuguqula amashejuli okulungisa kusukela ekulungisweni okusabela kuya ekuthuthukisweni okuhleliwe, okungabizi kakhulu.

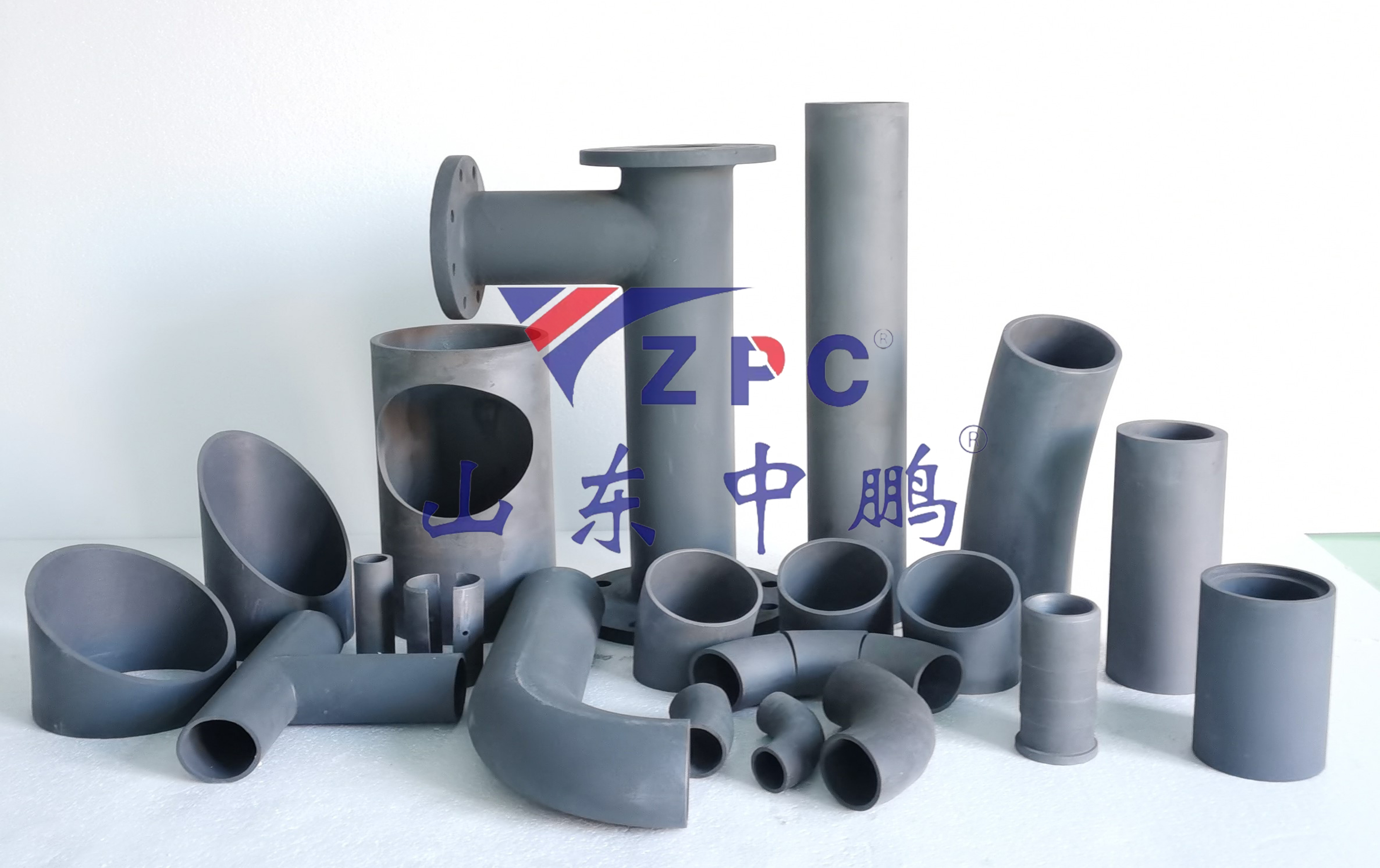

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.