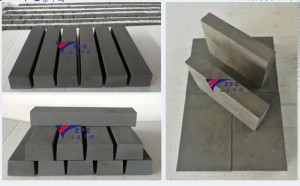

RBSC Silicon Carbide Cov vuas ceramic

RBSC Silicon Carbide Cov vuas ceramictau tshwm sim los ua qhov kev daws teeb meem zoo tshaj plaws rau kev tiv thaiv kev hnav thiab xeb hauv cov chaw ua haujlwm nyuaj. Cov vuas ceramic thiab cov ntaub pua plag no muab kev ua tau zoo tsis sib xws hauv cov txheej txheem tuav cov khoom siv, ua kom lub neej ntawm cov khoom siv ntev dua thaum ua kom zoo dua kev ua haujlwm ntawm cov txheej txheem tseem ceeb.

Kev Ua Haujlwm Zoo Tshaj Plaws

Peb cov khoom siv silicon carbide (SiC) uas ua tiav qhov kev ua tau zoo tshaj plaws los ntawm cov khoom siv tshwj xeeb:

- Mohs Hardness 9.5 (13 ntawm qhov hloov tshiab) rau kev tiv thaiv hnav hnyav heev

- 4–5 × muaj zog tawg ntau dua piv rau lwm cov SiC uas siv nitride-bonded

- 5–7 × lub neej ua haujlwm ntev dua piv rau cov ntaub alumina ib txwm muaj

- Kev tsis muaj zog tshuaj lom neeg tawm tsam cov kua qaub, alkalis, thiab cov kuab tshuaj organic (pH 0–14)

- Kev ruaj khov ntawm thermal tswj kev ncaj ncees ntawm -60 ° C txog 1650 ° C

Kev Tiv Thaiv Kev Kho Kom Haum Rau Koj

Muaj nyob rau hauv thicknesses los ntawm 8–45 hli, peb cov ceramic linings hloov kho rau ntau yam kev xav tau ua haujlwm:

- Kev teeb tsa tiv taus kev cuam tshuam rau cov chutes thiab hoppers

- Cov nto uas tsis muaj kev sib txhuam rau cov tshuab conveyor

- Cov qib purity siab rau cov khoom noj / tshuaj siv

- Cov qauv hluav taws xob rwb thaiv tsev rau cov chaw tawg

Cov Ntawv Thov Uas Muaj Kev Ua Tau Zoo

1. Cov Txheej Txheem Tswj Khoom Siv

- Cov kav dej slurry nrog 90% txo qis kev yaig

- Kev khawb av trommels nrog 3 × kev pabcuam txuas ntxiv

- Cov cua daj cua dub ntawm cov nroj tsuag cement uas muaj sia nyob tau 50,000+ teev ua haujlwm

2. Cov Khoom Siv Ua Haujlwm

- Cov ntaub thaiv thee uas tiv taus 120 m/s cov khoom me me

- Cov hlab ntsha tshuaj lom neeg uas tuav cov xov xwm corrosive

- Cov kav dej hlau cog rau cov ntoo tshauv uas ua rau cov hmoov av tawg

3. Cov Cheebtsam Tshwj Xeeb

- Cov txheej txheem ntawm cov hniav rotor rau cov centrifugal separators

- Cov phaj hnav rau kev ua biomass

- Cov ntxig rau cov duab sib txawv rau cov qauv geometries nyuaj

Kev Cuam Tshuam Txog Kev Lag Luam

Kev hloov mus rau silicon carbide linings qhia txog cov txiaj ntsig ntsuas tau:

- Txo 60–80% ntawm lub sijhawm tsis ua haujlwm uas tsis tau npaj tseg

- 45% txo cov nqi kho tas mus li

- 30% kev txuag hluav taws xob los ntawm kev siv cov khoom siv zoo tshaj plaws

- 90% rov ua dua tshiab ntawm cov khoom siv uas tau hnav lawm

Kev Teeb tsa & Kev Hloov Kho Tau

Tsim los rau kev sib koom ua ke tsis muaj teeb meem:

- Cov qauv modular nrog cov qauv sib txuas

- Muaj zog epoxy lossis kev kho khoom siv kho tshuab

- Kev pabcuam machining thiab retrofitting hauv qhov chaw

- Kev sib xws ntawm kev saib xyuas kev hnav khaub ncaws tiag tiag

Kev Tsim Kho Tshiab Uas Npaj Rau Yav Tom Ntej

Cov txheej txheem silicon carbide tiam tom ntej suav nrog:

- Cov qauv ntom ntom gradient rau kev nqus dej

- Kev kho mob nto uas siv lubricating rau nws tus kheej

- Kev taug qab hnav uas siv RFID

- Cov txheej txheem sib xyaw ua ke ntawm cov khoom siv ceramic-hlau

Txij li kev ua haujlwm hauv kev khawb av mus rau cov chaw ua tshuaj lom neeg, cov ntaub thaiv silicon carbide ceramic sawv cev rau tus qauv tshiab hauv kev tiv thaiv kev hnav hauv kev lag luam. Lawv qhov kev sib xyaw ua ke ntawm kev ua kom lub zog kho tshuab, kev ruaj khov ntawm tshuaj lom neeg, thiab kev ua kom lub zog thermal hloov pauv kev ua haujlwm ntawm cov khoom siv - txo cov nqi siv tas mus li thaum txhim kho kev ntseeg siab ntawm kev tsim khoom hauv ntiaj teb qhov chaw ua haujlwm abrasive tshaj plaws.

Shandong Zhongpeng Special Ceramics Co., Ltd yog ib qho ntawm cov khoom siv tshiab silicon carbide ceramic loj tshaj plaws hauv Suav teb. SiC technical ceramic: Moh qhov nyuaj yog 9 (New Moh qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. SiC cov khoom lub neej kev pabcuam yog 4 txog 5 zaug ntev dua li 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Cov txheej txheem hais nqe yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob rau tsis muaj leej twg. Peb ib txwm mob siab rau kev sib tw peb lub hom phiaj thiab muab peb lub siab rov qab rau lub zej zog.