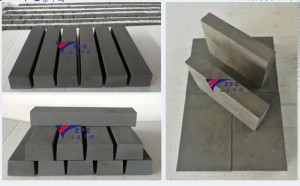

Amathayili e-ceramic e-RBSC Silicon Carbide

Amathayili e-ceramic e-RBSC Silicon CarbideKuvele njengesixazululo esihamba phambili sokulwa nokugqwala nokugqwala ezindaweni zezimboni ezidinga kakhulu. Lawa matayela e-ceramic aklanywe ngobunjiniyela kanye nama-lining aletha ukusebenza okungenakuqhathaniswa ezinhlelweni zokuphatha izinto, andise isikhathi sokuphila kwemishini ngenkathi enza ngcono ukusebenza kahle kuzo zonke izinqubo ezibalulekile.

Ukuphakama Kobunjiniyela

Izingxenye zethu ze-silicon carbide (SiC) ezenziwe ngokunemba ziphumelela kakhulu ngezakhiwo zezinto ezihlukile:

- Ukuqina kwe-Mohs 9.5(13 esikalini esibuyekeziwe) ukuze kuvinjwe ukuguguleka okukhulu

- Ukuqina okukhulu kokuqhekeka okungu-4–5× uma kuqhathaniswa nezinye izindlela ze-SiC eziboshwe yi-nitride

- Impilo yesevisi ende ngama-5–7× uma kuqhathaniswa ne-linings ye-alumina yendabuko

- Ukungasebenzi kahle kwamakhemikhali ngokumelene nama-asidi, ama-alkali, kanye nezinyibilikisi eziphilayo (pH 0–14)

- Ukuqina kokushisa okugcina ubuqotho kusukela ku--60°C kuya ku-1650°C

Izixazululo Zokuvikela Ezenziwe Ngokwezifiso

Itholakala ngobukhulu obusukela ku-8–45 mm, ama-lining ethu e-ceramic avumelana nezidingo zokusebenza ezahlukahlukene:

- Ukulungiswa okumelana nokushayisana kwama-chute nama-hopper

- Izindawo eziphansi zokungqubuzana kwezinhlelo zokuhambisa

- Amazinga aphezulu okuhlanzeka kokudla/emithi

- Izinhlobo zokuvikela ngogesi ezindaweni eziqhumayo

Izinhlelo Zokusebenza Eziqhutshwa Ukusebenza

1. Izinhlelo Zokuphatha Izinto

- Amapayipi odaka ancishisiwe ngo-90%

- Ama-trommel okumba anemijikelezo yesevisi enwetshiwe engu-3 ×

- Iziphepho zesitshalo sikasimende ezisinde emahoreni okusebenza angaphezu kuka-50,000

2. Imishini Yokucubungula

- Izindwangu zokugaya amalahle ezimelana nokushaywa yizinhlayiya ezingama-120 m/s

- Imikhumbi ye-reactor yamakhemikhali ephatha imidiya ebolile

- Amapayipi esitshalo sensimbi amelana nomlotha oqhumayo

3. Izingxenye Ezikhethekile

- Izembozo ze-Rotor blade zabahlukanisi be-centrifugal

- Gqoka amapuleti okucubungula i-biomass

- Izinto ezifakwe ngendlela oyifisayo zamajiyometri ayinkimbinkimbi

Umthelela Wezomnotho

Ukushintshela ku-silicon carbide linings kubonisa izinzuzo ezilinganisekayo:

- Ukwehla ngo-60–80% esikhathini sokuphumula esingahleliwe

- Izindleko zokulungisa impilo yonke eziphansi ngo-45%

- Ukonga amandla okungu-30% ngokugeleza kwezinto ezilungiselelwe kahle

- Ukusebenziseka kabusha okungu-90% kwezingxenye ezigugile

Ukufakwa Nokuzivumelanisa Nezimo

Yenzelwe ukuhlanganiswa okungenamthungo:

- Izinhlelo zamathayela ezihlanganisiwe ezinemiklamo exhumene

- Ukulungiswa kwe-epoxy enamandla aphezulu noma okwenziwa ngomshini

- Izinsizakalo zokulungisa nokulungisa endaweni

- Ukuhambisana kokuqapha ukugqoka ngesikhathi sangempela

Izinto Ezintsha Ezilungele Ikusasa

Izinhlobo ezilandelayo ze-silicon carbide linings zifaka:

- Izakhiwo zobuningi be-gradient zokumuncwa komthelela

- Ukwelashwa kobuso okuzigcoba ngokwakho

- Ukulandelela ukugqokwa okunikwe amandla yi-RFID

- Izinhlelo ezihlanganisiwe ze-ceramic-metal ze-hybrid

Kusukela emisebenzini yezimayini kuya ezitshalweni zokucubungula amakhemikhali, ulwelwesi lwe-silicon carbide ceramic lumelela indinganiso entsha ekuvikelweni kokuguguleka kwezimboni. Inhlanganisela yabo eyingqayizivele yokuqina komshini, ukuzinza kwamakhemikhali, kanye nokukhuthazela kokushisa kuguqula ukusebenza kwemishini - kunciphisa izindleko zomjikelezo wokuphila ngenkathi kuthuthukiswa ukuthembeka kokukhiqiza ezindaweni zokusebenza ezihlukumeza kakhulu emhlabeni.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.