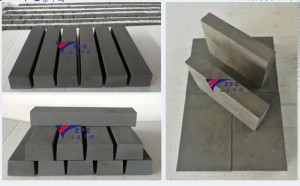

Lithaele tsa Ceramic tsa RBSC Silicon Carbide

Lithaele tsa Ceramic tsa RBSC Silicon Carbideli hlahile e le tharollo ea mantlha bakeng sa ho loantša ho tsofala le ho bola libakeng tse hlokang tlhokomelo e ngata tsa indasteri. Lithaele tsena tsa letsopa tse entsoeng ka boenjiniere le masela a ka hare a fana ka ts'ebetso e ke keng ea lekanngoa litsamaisong tsa ho sebetsana le thepa, li eketsa nako ea bophelo ba lisebelisoa ha li ntse li ntlafatsa bokhoni ba ts'ebetso ho pholletsa le lits'ebetso tsa bohlokoa.

Bophahamo ba Boenjiniere

Likarolo tsa rona tsa silicon carbide (SiC) tse entsoeng ka nepo li ipabola ka thepa e ikhethang ea thepa:

- Mohs Hardness 9.5(13 ka tekanyo e ntlafalitsoeng) bakeng sa ho hanyetsa ho tlola ho feteletseng

- Ho tiea ha ho robeha ho hoholo ka 4–5× khahlano le mekhoa e meng ea SiC e kopantsoeng le nitride

- Bophelo ba tšebeletso bo bolelele ba 5–7× ha bo bapisoa le masela a tloaelehileng a alumina

- Ho se sebetse hantle ha lik'hemik'hale khahlanong le li-acid, li-alkali le li-solvent tsa organic (pH 0–14)

- Botsitso ba mocheso bo bolokang botšepehi ho tloha ho -60°C ho isa ho 1650°C

Litharollo tsa Tšireletso tse Ikhethileng

Li-lining tsa rona tsa letsopa li fumaneha ka botenya ho tloha ho 8-45 mm, li ikamahanya le litlhoko tse fapaneng tsa ts'ebetso:

- Litlhophiso tse hanelang tshusumetso bakeng sa li-chute le li-hopper

- Libaka tse nang le khohlano e tlase bakeng sa litsamaiso tsa conveyor

- Meputso e phahameng bakeng sa lijo/litšebeliso tsa meriana

- Mefuta e thibelang mocheso ka motlakase bakeng sa libaka tse phatlohang

Likopo tse Tsamaiswang ke Tshebetso

1. Mekhoa ea ho Sebelisa Lintho

- Liphaephe tsa lerōle tse nang le khoholeho e fokotsehileng ka 90%

- Li-trommel tsa merafo tse nang le lipotoloho tse atolositsoeng tsa tšebeletso ea 3×

- Maholiotsoana a feme ea samente a pholohile lihora tse fetang 50,000 tsa ts'ebetso

2. Lisebelisoa tsa ho Sebetsa

- Masela a pulverizer a mashala a hanelang litšusumetso tsa likaroloana tsa 120 m/s

- Mekepe ea lik'hemik'hale e sebetsanang le mecha ea phatlalatso e senyang

- Liphaephe tsa fektheri ea tšepe tse mamellang molora o khorofo oa ntsintsi

3. Likarolo tse Ikhethileng

- Liaparo tsa lehare la rotor bakeng sa li-separator tsa centrifugal

- Roala lipoleiti bakeng sa ts'ebetso ea biomass

- Li-insert tse bōpehileng joaloka motho ka mong bakeng sa li-geometri tse rarahaneng

Tšusumetso ea Moruo

Phetoho ho ea ho li-lining tsa silicon carbide e bontša melemo e ka lekanngoang:

- Phokotso ea 60–80% nakong ea phomolo e sa reroang

- Litšenyehelo tsa tlhokomelo tsa bophelo bohle tse tlase ka 45%

- Pholoso ea matla ea 30% ka phallo e ntlafalitsoeng ea thepa

- 90% ea ho sebelisoa hape ha likarolo tse tsofetseng

Ho kenya le ho ikamahanya le maemo

E entsoe bakeng sa kopanyo e se nang sekoli:

- Mekhoa ea lithaele tsa modular tse nang le meralo e hokahaneng

- Epoxy e matla haholo kapa ho lokisa mechine

- Litšebeletso tsa ho lokisa le ho lokisa sebakeng seo

- Ho tsamaisana ha tlhokomelo ea ho roala ka nako ea sebele

Mekhoa e Mecha e Lokiselitsoeng Bokamoso

Lithako tsa silicon carbide tsa moloko o latelang li kenyelletsa:

- Meaho ea gradient e teteaneng bakeng sa ho monya tšusumetso

- Mekhoa ea ho itlotsa holim'a metsi

- Ho latela ho roala ho nolofalitsoeng ke RFID

- Mekhoa e kopaneng ea tšepe e kopantsoeng ea ceramic-steel

Ho tloha mesebetsing ea merafo ho ea lifemeng tsa ts'ebetso ea lik'hemik'hale, masela a letsopa a silicon carbide a emela maemo a macha a tšireletso ea ho robeha ha indasteri. Motsoako oa bona o ikhethang oa ho mamella mechine, botsitso ba lik'hemik'hale le mamello ea mocheso o fetola ts'ebetso ea lisebelisoa - ho fokotsa litšenyehelo tsa potoloho ea bophelo ha ka nako e ts'oanang ho ntlafatsa ts'epo ea tlhahiso libakeng tsa ts'ebetso tse matla ka ho fetisisa lefatšeng.

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.