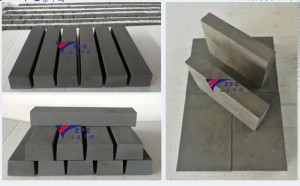

RBSC Silicon Carbide Ceramic mataira

RBSC Silicon Carbide Ceramic matairaDzakabuda senzira yepamusoro yekurwisa kusakara nekuora munzvimbo dzinodiwa mumaindasitiri. Mataira aya eceramic nema linings akagadzirwa nemaoko anopa mashandiro asina kuenzana mukugadzirisa zvinhu, achiwedzera hupenyu hwemidziyo uku achivandudza mashandiro ekushanda kwayo mumabasa akakosha.

Hunhu Hwepamusoro hweUinjiniya

Zvikamu zvedu zvesilicon carbide (SiC) zvakagadzirwa nemazvo zvinobudirira kuburikidza nehunhu hwakasarudzika hwezvinhu:

- Kuomarara kweMohs 9.5 (13 pachiyero chakagadziridzwa) kuti isanyanya kupfekwa

- Kusimba kukuru kwekutyoka kwe 4–5× zvichienzaniswa nedzimwe nzira dzeSiC dzakasungirirwa ne nitride

- Hupenyu hwekushanda hwakareba 5–7× zvichienzaniswa nejira rekare realumina

- Kusashanda kwemakemikari pakurwisa acids, alkalis, uye organic solvents (pH 0–14)

- Kugadzikana kwekupisa kunochengetedza kuvimbika kubva -60°C kusvika 1650°C

Mhinduro dzeDziviriro Dzakagadzirirwa

Inowanikwa muukobvu kubva pa8–45 mm, machira edu eceramic anochinjika kune zvakasiyana-siyana zvinodiwa pakushanda:

- Magadzirirwo anodzivirira kukanganiswa kwemachute nemahopper

- Nzvimbo dzisinganyanyi kukweshana dzemasisitimu ekutakura zvinhu

- Magiredhi ekuchena kwakanyanya ekushandisa chikafu/mishonga

- Mhando dzemagetsi dzinodzivirira nharaunda dzinoputika

Mapurogiramu Anotungamirirwa Nekushanda

1. Masisitimu Ekubata Zvinhu

- Mapaipi ane matope akaderedzwa ne90%

- Matrommels ekuchera ane mashandisirwo akareba e3 ×

- Madutu emiti yesimende akapona maawa anopfuura 50,000 ekushanda

2. Midziyo Yokugadzirisa

- Matanda emarasha anopwanya marasha anodzivirira kuputika kwezvikamu zve120 m/s

- Midziyo yemakemikari inotakura zvinhu zvinoparadza

- Mapaipi esimbi emiti anotsungirira madota anobhururuka

3. Zvikamu Zvakakosha

- Rotor blade coatings ye centrifugal separators

- Pfeka maplate ekugadzirisa biomass

- Zvishongedzo zvakagadzirwa nechimiro che geometri dzakaoma

Mhedzisiro Yezvehupfumi

Kuchinja kuenda ku silicon carbide linings kunoratidza mabhenefiti anoyerwa:

- Kuderedzwa kwe60–80% kwenguva yekumbozorora isina kurongwa

- 45% mari yekuchengetedza hupenyu hwese yakaderera

- 30% kuchengetedza simba kuburikidza nekuyerera kwezvinhu zvakagadziriswa

- 90% yekudzokorodza zvinhu zvakasakara

Kuiswa & Kuchinjika

Yakagadzirwa kuti isanganisirwe zvakanaka:

- Masisitimu emataira emodular ane magadzirirwo akabatana

- Kugadziriswa kwe epoxy yakasimba kana kuti yemakanika

- Masevhisi ekugadzira nekugadzirisa panzvimbo yacho

- Kuenderana kwekutarisa kupfeka munguva chaiyo

Zvitsva Zvakagadzirira Ramangwana

Zvigadzirwa zvesilicon carbide zvechizvarwa chinotevera zvinosanganisira:

- Maumbirwo ehuwandu hwegiraidi ekushandisa simba

- Kuzvizora pamusoro pemvura pachako

- Kutevera kupfeka kunogoneswa neRFID

- Masisitimu esimbi akagadzirwa nesimbi yehybrid

Kubva pamabasa ekuchera kusvika kumafekitori ekugadzirisa makemikari, simbi dzesimbi dzesilicon carbide dzinomiririra mwero mutsva wekudzivirira kupfeka kwemaindasitiri. Musanganiswa wavo wakasiyana wekutsungirira kwemuchina, kugadzikana kwemakemikari, uye kutsungirira kwekupisa kunoshandura mashandiro emuchina - kuderedza mitengo yehupenyu uku uchivandudza kuvimbika kwekugadzira munzvimbo dzekushanda dzakanyanyisa pasi rose.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.