In many industrial production scenarios, it is often necessary to transport slurries containing solid particles, such as mineral slurries in mines, ash residues in power plants, and smelting liquids in the metallurgical industry. These slurries have strong corrosiveness and high wear resistance, which puts extremely high demands on conveying equipment. The silicon carbide slurry pump emerged in response to this demand and has become a cornerstone in the industrial conveying field.

1、 Working principle

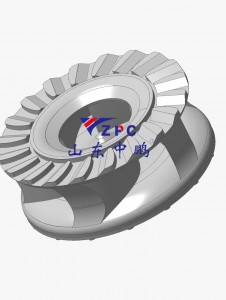

The silicon carbide slurry pump is mainly based on the working principle of centrifugal pumps. When the motor drives the pump shaft to rotate at high speed, the impeller connected to the pump shaft also rotates at high speed. The blades on the impeller will push the surrounding liquid to rotate together. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge, and the speed and pressure are both increased. At this point, a low-pressure area is formed at the center of the impeller, and the external slurry continuously enters the pump body through the suction pipe under the action of atmospheric pressure, supplementing the low-pressure area at the center of the impeller. The high-speed liquid ejected from the outer edge of the impeller enters the volute shaped pump body, which further converts the kinetic energy of the liquid into pressure energy, ultimately causing the slurry to be discharged from the discharge pipe at a higher pressure, achieving continuous and stable transportation.

2、 Core advantages

1. Super abrasion resistance

Silicon carbide itself has extremely high hardness, second only to diamond in terms of Mohs hardness. This greatly reduces the wear rate of the flow-through components of the silicon carbide slurry pump when facing slurry containing a large number of hard solid particles. Compared to traditional metal slurry pumps, the service life of silicon carbide slurry pumps can be extended several times, reducing the frequency of equipment replacement and maintenance, and improving production continuity and stability.

2. Excellent corrosion resistance

Silicon carbide has good chemical stability and can withstand corrosion from almost all inorganic acids, organic acids, and bases. In some chemical, metallurgical, and other industries, slag slurry often has strong corrosiveness. The use of silicon carbide slurry pumps can effectively resist the erosion of chemical substances, ensure the normal operation of equipment, and avoid safety hazards such as leakage and equipment damage caused by corrosion.

3. High temperature stability

Silicon carbide also has the characteristic of high temperature resistance, which can withstand temperatures up to 1350 ℃. In some high-temperature industrial scenarios, such as the transportation of high-temperature slurry, silicon carbide slurry pumps can maintain stable performance and will not deform or be damaged due to high temperatures, adapting to harsh working environments.

3、 Application Fields

1. Mining industry

In the process of mining and beneficiation, it is necessary to transport a large amount of slurry containing various ore particles. These slurries not only have high concentration, but also have high hardness of ore particles, which causes severe wear on the conveying pump. Silicon carbide slurry pump, with its excellent wear resistance and corrosion resistance, can efficiently and stably transport slurry, improve mining production efficiency, and reduce operating costs.

2. Metallurgical industry

Metallurgical production involves the transportation of various high-temperature and highly corrosive smelting liquids and slag. The silicon carbide slurry pump can withstand high temperatures and resist chemical corrosion, meeting the strict requirements of the metallurgical industry for conveying equipment and ensuring the smooth progress of the production process.

3. Power industry

Power plants generate a large amount of ash residue after coal combustion, which needs to be transported to designated locations for processing through slurry pumps. The silicon carbide slurry pump can effectively cope with the wear and tear of ash, ensure the reliable operation of the ash conveying system, and assist in the environmentally friendly production of power plants.

4. Chemical industry

Chemical production often comes into contact with various highly corrosive liquids and slurries containing solid particles. The excellent corrosion resistance of silicon carbide slurry pumps has made them widely used in the chemical industry, ensuring the safety and stability of chemical production.

The silicon carbide slurry pump has become an indispensable key equipment for industrial transportation due to its unique working principle, excellent performance advantages, and wide application fields. With the continuous development of industrial technology, silicon carbide slurry pumps will also continue to innovate and upgrade, providing a more solid guarantee for efficient production in various industries.

Post time: Jul-12-2025