Hauv ntau qhov xwm txheej kev tsim khoom lag luam, nws feem ntau tsim nyog los thauj cov slurries uas muaj cov khoom khov, xws li cov mineral slurries hauv cov mines, cov tshauv seem hauv cov chaw tsim hluav taws xob, thiab cov kua smelting hauv kev lag luam metallurgical. Cov slurries no muaj zog corrosiveness thiab siab hnav tsis kam, uas ua rau muaj kev xav tau siab heev rau cov khoom siv thauj khoom. Lubsilicon carbide slurry twj tso kua mistau tshwm sim los teb rau qhov kev thov no thiab tau dhau los ua lub hauv paus tseem ceeb hauv kev lag luam xa khoom.

1, Txoj Cai Ua Haujlwm

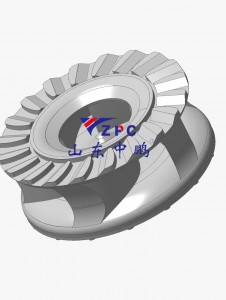

Lub twj tso kua silicon carbide slurry feem ntau yog ua raws li lub hauv paus ntsiab lus ua haujlwm ntawm cov twj centrifugal. Thaum lub cev muaj zog tsav lub twj tso kua kom tig ntawm qhov ceev ceev, lub impeller txuas nrog lub twj tso kua kuj tig ntawm qhov ceev ceev. Cov hniav ntawm lub impeller yuav thawb cov kua ib puag ncig kom tig ua ke. Nyob rau hauv qhov kev ua ntawm lub zog centrifugal, cov kua raug pov los ntawm qhov chaw ntawm lub impeller mus rau ntug sab nraud, thiab qhov ceev thiab siab ob qho tib si nce. Ntawm lub sijhawm no, thaj chaw qis-siab tau tsim nyob rau hauv qhov chaw ntawm lub impeller, thiab cov slurry sab nraud txuas ntxiv mus rau hauv lub cev twj tso kua los ntawm cov yeeb nkab nqus nyob rau hauv qhov kev ua ntawm lub siab atmospheric, ntxiv rau thaj chaw qis-siab ntawm qhov chaw ntawm lub impeller. Cov kua ceev ceev uas raug rho tawm ntawm ntug sab nraud ntawm lub impeller nkag mus rau hauv lub cev twj tso kua zoo li volute, uas ntxiv hloov lub zog kinetic ntawm cov kua mus rau hauv lub zog siab, thaum kawg ua rau cov slurry raug tso tawm ntawm cov yeeb nkab tawm ntawm qhov siab dua, ua tiav kev thauj mus los tas mus li thiab ruaj khov.

2, Cov txiaj ntsig tseem ceeb

1. Kev tiv thaiv kev puas tsuaj loj heev

Silicon carbide nws tus kheej muaj qhov nyuaj heev, thib ob tsuas yog pob zeb diamond hauv Mohs hardness. Qhov no txo qhov hnav ntawm cov khoom ntws ntawm cov twj tso kua mis silicon carbide thaum ntsib cov slurry uas muaj ntau cov khoom tawv. Piv nrog rau cov twj tso kua mis hlau ib txwm muaj, lub neej ua haujlwm ntawm cov twj tso kua mis silicon carbide slurry tuaj yeem ntev dua ntau zaus, txo qhov zaus ntawm kev hloov khoom siv thiab kev saib xyuas, thiab txhim kho kev ua haujlwm thiab kev ruaj khov ntawm kev tsim khoom.

2. Kev tiv thaiv xeb zoo heev

Silicon carbide muaj kev ruaj khov tshuaj zoo thiab tuaj yeem tiv taus xeb los ntawm yuav luag txhua yam inorganic acids, organic acids, thiab cov hauv paus. Hauv qee qhov kev lag luam tshuaj lom neeg, metallurgical, thiab lwm yam lag luam, slag slurry feem ntau muaj zog corrosiveness. Kev siv cov twj tso kua mis silicon carbide slurry tuaj yeem tiv taus kev yaig ntawm cov tshuaj lom neeg, xyuas kom meej tias cov khoom siv ua haujlwm ib txwm muaj, thiab zam kev phom sij kev nyab xeeb xws li xau thiab cov khoom siv puas tsuaj los ntawm kev xeb.

3. Kev ruaj khov kub siab

Silicon carbide kuj muaj tus yam ntxwv ntawm kev tiv taus kub siab, uas tuaj yeem tiv taus kub txog li 1350 ℃. Hauv qee qhov xwm txheej kub siab, xws li kev thauj mus los ntawm cov dej kub siab, cov twj tso kua silicon carbide slurry tuaj yeem tswj tau qhov ua tau zoo thiab yuav tsis deform lossis puas tsuaj vim kub siab, hloov kho rau qhov chaw ua haujlwm hnyav.

3, Cov Ntawv Thov

1. Kev lag luam tsuas

Thaum lub sijhawm khawb av thiab ua kom zoo, yuav tsum thauj cov slurry ntau ntau uas muaj ntau yam ore pieces. Cov slurries no tsis yog tsuas yog muaj cov concentration siab xwb, tab sis kuj muaj cov ore pieces tawv heev, uas ua rau lub twj tso kua mis hnav hnyav heev. Silicon carbide slurry twj tso kua mis, nrog nws qhov kev tiv thaiv kev hnav thiab kev tiv thaiv corrosion zoo heev, tuaj yeem thauj slurry tau zoo thiab ruaj khov, txhim kho kev tsim khoom hauv av, thiab txo cov nqi khiav lag luam.

2. Kev lag luam hlau

Kev tsim cov hlau ua los ntawm hlau suav nrog kev thauj mus los ntawm ntau yam kua dej kub thiab cov kua nplaum uas muaj zog heev. Lub twj tso kua nplaum silicon carbide tuaj yeem tiv taus qhov kub siab thiab tiv taus kev xeb ntawm cov tshuaj lom neeg, ua tau raws li cov kev cai nruj ntawm kev lag luam hlau rau kev xa cov khoom siv thiab xyuas kom meej tias cov txheej txheem ntau lawm zoo.

3. Kev lag luam fais fab

Cov chaw tsim hluav taws xob tsim cov tshauv seem ntau tom qab hlawv thee, uas yuav tsum tau thauj mus rau qhov chaw tshwj xeeb rau kev ua tiav los ntawm cov twj tso kua nplaum. Lub twj tso kua nplaum silicon carbide tuaj yeem tiv taus qhov hnav thiab tsim kua muag ntawm cov tshauv, xyuas kom meej tias lub kaw lus thauj cov tshauv ua haujlwm tau zoo, thiab pab txhawb kev tsim hluav taws xob uas tsis ua rau ib puag ncig puas tsuaj.

4. Kev lag luam tshuaj lom neeg

Kev tsim tshuaj feem ntau los sib cuag nrog ntau yam kua dej thiab cov slurries uas muaj cov khoom khov kho. Qhov kev tiv thaiv corrosion zoo heev ntawm silicon carbide slurry twj tso kua mis tau ua rau lawv siv dav hauv kev lag luam tshuaj lom neeg, ua kom muaj kev nyab xeeb thiab ruaj khov ntawm kev tsim tshuaj.

Lub twj tso kua nplaum silicon carbide tau dhau los ua cov khoom siv tseem ceeb rau kev thauj mus los hauv kev lag luam vim nws txoj hauv kev ua haujlwm tshwj xeeb, kev ua tau zoo heev, thiab cov chaw siv dav. Nrog rau kev txhim kho tas mus li ntawm cov thev naus laus zis hauv kev lag luam, cov twj tso kua nplaum silicon carbide kuj tseem yuav txuas ntxiv tsim kho tshiab thiab txhim kho, muab kev lees paub zoo dua rau kev tsim khoom zoo hauv ntau yam lag luam.

Lub sijhawm tshaj tawm: Lub Xya Hli-12-2025