Ezimweni eziningi zokukhiqiza ezimbonini, kuvame ukudingeka ukuthutha ama-slurry aqukethe izinhlayiya eziqinile, njenge-slurry yamaminerali ezimayini, izinsalela zomlotha ezitshalweni zikagesi, kanye noketshezi lokuncibilikisa embonini yensimbi. Lawa ma-slurry anokugqwala okunamandla kanye nokumelana nokuguguleka okuphezulu, okubeka izidingo eziphezulu kakhulu emishinini yokuthutha.ipompo ye-silicon carbide slurrykwavela ngenxa yalesi sidingo futhi sekuyisisekelo emkhakheni wokuthutha izimpahla zezimboni.

1, isimiso sokusebenza

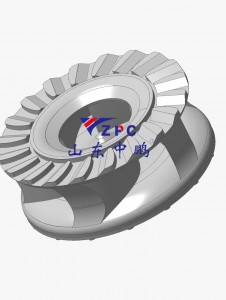

Iphampu ye-silicon carbide slurry isekelwe kakhulu esimisweni sokusebenza samaphampu e-centrifugal. Lapho injini iqhuba umgodi wephampu ukuze ujikeleze ngesivinini esikhulu, i-impeller exhunywe kumgodi wephampu nayo ijikeleza ngesivinini esikhulu. Ama-blade ku-impeller azosunduza uketshezi oluzungezile ukuze lujikeleze ndawonye. Ngaphansi kwesenzo samandla e-centrifugal, uketshezi luphonswa kusukela maphakathi ne-impeller kuya emaphethelweni angaphandle, futhi isivinini kanye nokucindezela kokubili kuyakhushulwa. Kuleli qophelo, kwakheka indawo enengcindezi ephansi maphakathi ne-impeller, kanti i-slurry yangaphandle ingena njalo emzimbeni wephampu ngephayiphi yokumunca ngaphansi kwesenzo sengcindezi yomoya, inezela endaweni enengcindezi ephansi maphakathi ne-impeller. Uketshezi olusheshayo olukhishwa emaphethelweni angaphandle e-impeller lungena emzimbeni wephampu onesimo se-volute, okuguqula amandla e-kinetic oketshezi abe amandla okucindezela, ekugcineni okubangela ukuthi i-slurry ikhishwe ephayiphini lokukhipha ngokucindezela okuphezulu, kufezwe ukuthuthwa okuqhubekayo nokuzinzile.

2, Izinzuzo Eziyinhloko

1. Ukumelana nokuklwebheka okukhulu

I-silicon carbide ngokwayo inobulukhuni obuphezulu kakhulu, ilandela idayimane kuphela ngobunzima be-Mohs. Lokhu kunciphisa kakhulu izinga lokuguguleka kwezingxenye zokugeleza kwephampu ye-silicon carbide slurry lapho ibhekene ne-slurry equkethe inani elikhulu lezinhlayiya eziqinile eziqinile. Uma kuqhathaniswa namaphampu ensimbi endabuko, impilo yesevisi yamaphampu e-silicon carbide slurry ingandiswa izikhathi eziningana, kuncishiswe imvamisa yokushintsha nokulungisa imishini, futhi kuthuthukiswe ukuqhubeka kokukhiqiza nokuzinza.

2. Ukumelana okuhle kakhulu kokugqwala

I-silicon carbide inamandla amahle okuqina kwamakhemikhali futhi ingamelana nokugqwala okuvela cishe kuzo zonke izinhlobo zama-asidi angaphili, ama-asidi e-organic, kanye nezisekelo. Kwezinye izimboni zamakhemikhali, ezensimbi, kanye nezinye, i-slag slurry ivame ukuba nokugqwala okunamandla. Ukusetshenziswa kwamaphampu e-silicon carbide slurry kungamelana ngempumelelo nokuguguleka kwezinto zamakhemikhali, kuqinisekise ukusebenza okuvamile kwemishini, futhi kugweme izingozi zokuphepha njengokuvuza kanye nomonakalo wemishini obangelwa ukugqwala.

3. Ukuqina kokushisa okuphezulu

I-silicon carbide nayo inesici sokumelana nokushisa okuphezulu, okungamelana namazinga okushisa afinyelela ku-1350 ℃. Kwezinye izimo zezimboni ezishisa kakhulu, njengokuthuthwa kwe-slurry eshisa kakhulu, amaphampu e-slurry e-silicon carbide angagcina ukusebenza okuzinzile futhi ngeke aguquguquke noma alimale ngenxa yokushisa okuphezulu, azivumelanise nezimo zokusebenza ezinzima.

3, Izinkambu Zohlelo Lokusebenza

1. Imboni yezimayini

Enkambisweni yokumba nokuthuthukisa, kuyadingeka ukuthutha inani elikhulu le-slurry equkethe izinhlayiya ze-ore ezahlukahlukene. Lawa ma-slurry awagcini nje ngokuba nokuhlushwa okuphezulu, kodwa futhi anobulukhuni obukhulu bezinhlayiya ze-ore, okubangela ukuguguleka okukhulu epompo yokudlulisa. Ipompo ye-slurry ye-silicon carbide, enokumelana kwayo okuhle kakhulu nokuguguleka, ingathutha i-slurry ngempumelelo nangokuzinzile, ithuthukise ukusebenza kahle kokukhiqizwa kwemigodi, futhi inciphise izindleko zokusebenza.

2. Imboni yezinsimbi

Ukukhiqizwa kwensimbi kuhilela ukuthuthwa kwezinhlobo ezahlukene zoketshezi lokuncibilikisa olushisa kakhulu noludlaka kakhulu kanye ne-slag. Iphampu ye-silicon carbide slurry ingamelana namazinga okushisa aphezulu futhi imelane nokugqwala kwamakhemikhali, ihlangabezane nezidingo eziqinile zemboni yensimbi yokuhambisa imishini nokuqinisekisa inqubekela phambili ebushelelezi yenqubo yokukhiqiza.

3. Imboni yamandla

Izitshalo zikagesi zikhiqiza inani elikhulu lezinsalela zomlotha ngemva kokushiswa kwamalahle, okudingeka zithuthwe ziye ezindaweni ezikhethiwe ukuze zicutshungulwe ngamaphampu e-slurry. Iphampu ye-slurry ye-silicon carbide ingabhekana ngempumelelo nokuguguleka komlotha, iqinisekise ukusebenza okuthembekile kohlelo lokuhambisa umlotha, futhi isize ekukhiqizweni kwezitshalo zikagesi ezinobungani nemvelo.

4. Imboni yamakhemikhali

Ukukhiqizwa kwamakhemikhali kuvame ukuhlangana noketshezi oluhlukahlukene olubola kakhulu kanye nama-slurry aqukethe izinhlayiya eziqinile. Ukumelana okuhle kakhulu nokugqwala kwamaphampu e-slurry e-silicon carbide kuwenze asetshenziswa kabanzi embonini yamakhemikhali, okuqinisekisa ukuphepha nokuzinza kokukhiqizwa kwamakhemikhali.

Iphampu ye-silicon carbide slurry isibe yimishini ebalulekile yokuthutha izimboni ngenxa yesimiso sayo esiyingqayizivele sokusebenza, izinzuzo zokusebenza ezinhle kakhulu, kanye nezinkambu zokusetshenziswa ezibanzi. Ngokuthuthuka okuqhubekayo kobuchwepheshe bezimboni, amaphampu e-silicon carbide slurry azoqhubeka nokusungula izinto ezintsha nokuthuthukisa, anikeze isiqinisekiso esiqinile sokukhiqiza okuphumelelayo ezimbonini ezahlukahlukene.

Isikhathi sokuthunyelwe: Julayi-12-2025