Maemong a mangata a tlhahiso ea indasteri, hangata ho hlokahala ho tsamaisa marotholi a nang le likaroloana tse tiileng, joalo ka marotholi a liminerale merafong, masalla a molora lifemeng tsa motlakase, le metsi a qhibilihisang indastering ea tšepe. Marotholi ana a na le matla a ho bola le ho hanyetsa ho tsofala ho hoholo, e leng se behang litlhoko tse phahameng haholo lisebelisoa tsa ho tsamaisa.pompo ea slurry ea silicon carbidee hlahile ho arabela tlhoko ena mme e se e le lejwe la motheo lefapheng la ho tsamaisa thepa ya diindasteri.

1, Molao-motheo oa ho sebetsa

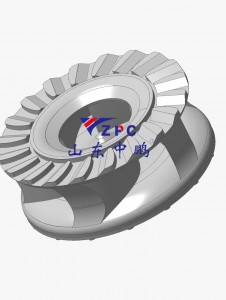

Pompo ea slurry ea silicon carbide e thehiloe haholo-holo molao-motheong oa ts'ebetso ea lipompo tsa centrifugal. Ha enjene e khanna shaft ea pompo ho potoloha ka lebelo le phahameng, impeller e hokahaneng le shaft ea pompo le eona e potoloha ka lebelo le phahameng. Mahare a impeller a tla sutumelletsa mokelikeli o potolohileng ho potoloha hammoho. Tlas'a ts'ebetso ea matla a centrifugal, mokelikeli o lahleloa ho tloha bohareng ba impeller ho ea moeling o ka ntle, 'me lebelo le khatello ka bobeli lia eketseha. Ntlheng ena, sebaka se nang le khatello e tlase se thehoa bohareng ba impeller, 'me slurry ea kantle e kena ka ho sa feleng 'meleng oa pompo ka phaephe ea ho hula tlas'a ts'ebetso ea khatello ea sepakapaka, e tlatsetsang sebaka se nang le khatello e tlase bohareng ba impeller. Mokelikeli o lebelo le phahameng o ntšitsoeng moeling o ka ntle oa impeller o kena 'meleng oa pompo o bōpehileng joaloka volute, e leng se fetolelang matla a kinetic a mokelikeli hore e be matla a khatello, qetellong se etsa hore slurry e ntšoe phaepheng ea ho ntša ka khatello e phahameng, e fihlelle lipalangoang tse tsoelang pele le tse tsitsitseng.

2, Melemo ea mantlha

1. Khanyetso e matla ea ho khohlela

Silicon carbide ka boeona e na le bothata bo phahameng haholo, e latela daemane feela ka bothata ba Mohs. Sena se fokotsa haholo sekhahla sa ho tsofala ha likarolo tsa phallo ea pompo ea slurry ea silicon carbide ha li tobane le slurry e nang le palo e kholo ea likaroloana tse tiileng tse thata. Ha li bapisoa le lipompo tsa slurry tsa tšepe tsa setso, bophelo ba tšebeletso ea lipompo tsa slurry tsa silicon carbide bo ka atolosoa ka makhetlo a 'maloa, ho fokotsa makhetlo a ho nkeloa sebaka le tlhokomelo ea lisebelisoa, le ho ntlafatsa tsoelo-pele ea tlhahiso le botsitso.

2. Khanyetso e ntle ea ts'enyeho

Silicon carbide e na le botsitso bo botle ba lik'hemik'hale 'me e ka mamella mafome a tsoang hoo e ka bang li-acid tsohle tse sa pheleng, li-acid tsa organic le metheo. Liindastering tse ling tsa lik'hemik'hale, tsa metallurgical, le tse ling, slurry ea slag hangata e na le matla a ho bola a matla. Tšebeliso ea lipompo tsa slurry ea silicon carbide e ka hanela ho senyeha ha lintho tsa lik'hemik'hale ka katleho, ea netefatsa ts'ebetso e tloaelehileng ea lisebelisoa, le ho qoba likotsi tsa polokeho tse kang ho lutla le tšenyo ea lisebelisoa e bakoang ke mafome.

3. Boiketlo ba mocheso o phahameng

Silicon carbide e boetse e na le tšobotsi ea ho hanyetsa mocheso o phahameng, e ka mamellang mocheso o fihlang ho 1350 ℃. Maemong a mang a indasteri a mocheso o phahameng, joalo ka ho tsamaisoa ha slurry ea mocheso o phahameng, lipompo tsa slurry tsa silicon carbide li ka boloka ts'ebetso e tsitsitseng 'me li ke ke tsa senyeha kapa tsa senyeha ka lebaka la mocheso o phahameng, li ikamahanya le maemo a thata a mosebetsi.

3, Masimo a Kopo

1. Indasteri ea merafo

Mokgweng wa ho tjheka le ho ntlafatsa boleng ba metsi, ho hlokahala ho tsamaisa bongata bo boholo ba lerōle le nang le dikarolwana tse fapaneng tsa lerōle. Lerōle lena ha le na feela mahloriso a phahameng, empa hape le na le ho thatafala ho hoholo ha dikarolwana tsa lerōle, e leng se bakang ho tsofala ho hoholo pompong e tsamaisang thepa. Pompo ea lerōle ea silicon carbide, e nang le khanyetso e ntle ea ho tsofala le khanyetso ea mafome, e ka tsamaisa lerōle ka katleho le ka botsitso, ea ntlafatsa katleho ea tlhahiso ea merafo, le ho fokotsa litšenyehelo tsa ts'ebetso.

2. Indasteri ea tšepe

Tlhahiso ea tšepe e kenyelletsa ho tsamaisoa ha mekelikeli e fapaneng ea ho qhibilihisa le slag e nang le mocheso o phahameng le e senyang haholo. Pompo ea slurry ea silicon carbide e ka mamella mocheso o phahameng le ho hanela ho bola ha lik'hemik'hale, e fihlela litlhoko tse tiileng tsa indasteri ea tšepe bakeng sa ho tsamaisa lisebelisoa le ho netefatsa tsoelo-pele e boreleli ea ts'ebetso ea tlhahiso.

3. Indasteri ea motlakase

Litsi tsa motlakase li hlahisa masalla a mangata a molora ka mor'a ho chesoa ha mashala, a hlokang ho isoa libakeng tse khethiloeng bakeng sa ho sebetsoa ka lipompo tsa seretse. Pompo ea seretse sa silicon carbide e ka sebetsana ka katleho le ho senyeha le ho taboha ha molora, ea netefatsa ts'ebetso e tšepahalang ea sistimi ea ho tsamaisa molora, le ho thusa tlhahisong ea litsi tsa motlakase e sa senyeng tikoloho.

4. Indasteri ea lik'hemik'hale

Tlhahiso ea lik'hemik'hale hangata e kopana le metsi a fapaneng a senyang haholo le marotholi a nang le likaroloana tse tiileng. Ho hanyetsa ho ts'oha ho hoholo ha lipompo tsa slurry tsa silicon carbide ho entse hore li sebelisoe haholo indastering ea lik'hemik'hale, ho netefatsa polokeho le botsitso ba tlhahiso ea lik'hemik'hale.

Pompo ea slurry ea silicon carbide e fetohile sesebelisoa sa bohlokoa sa bohlokoa bakeng sa lipalangoang tsa indasteri ka lebaka la molao-motheo oa eona o ikhethang oa ts'ebetso, melemo e metle ea ts'ebetso, le masimo a mangata a ts'ebeliso. Ka nts'etsopele e tsoelang pele ea theknoloji ea indasteri, lipompo tsa slurry tsa silicon carbide le tsona li tla tsoela pele ho ntlafatsa le ho ntlafatsa, li fana ka tiisetso e tiileng haholoanyane bakeng sa tlhahiso e sebetsang hantle liindastering tse fapaneng.

Nako ea poso: Phupu-12-2025