Kwiimeko ezininzi zemveliso yemizi-mveliso, kudla ngokuba yimfuneko ukuthutha amaqhekeza aqinileyo aqulethe izinto eziqinileyo, ezifana namaqhekeza amaminerali kwimigodi, amaqhekeza othuthu kwizityalo zamandla, kunye nezinto zokunyibilikisa ulwelo kwishishini lesinyithi. La maqhekeza anamandla okubola kunye nokumelana nokuguguleka okuphezulu, nto leyo ebeka iimfuno eziphezulu kakhulu kwizixhobo zokuhambisa.impompo yodaka lwesilicon carbideyavela ngenxa yesi sidingo kwaye iye yaba lilitye lembombo kwicandelo lokuthutha impahla kwimizi-mveliso.

1, Umgaqo wokusebenza

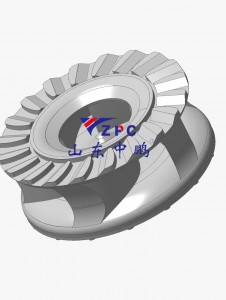

Ipompo ye-silicon carbide slurry isekelwe kakhulu kumgaqo wokusebenza kweepompo ze-centrifugal. Xa injini iqhuba i-pump shaft ukuba ijikeleze ngesantya esiphezulu, i-impeller eqhagamshelwe kwi-pump shaft nayo ijikeleza ngesantya esiphezulu. Iiblades kwi-impeller ziya kutyhala ulwelo olujikelezileyo ukuba lujikeleze kunye. Phantsi kwesenzo samandla e-centrifugal, ulwelo luphoswa ukusuka embindini we-impeller ukuya kumda wangaphandle, kwaye isantya kunye noxinzelelo zombini ziyanda. Kule ndawo, indawo enoxinzelelo oluphantsi yenziwa embindini we-impeller, kwaye i-slurry yangaphandle ingena rhoqo emzimbeni we-pump ngepayipi yokufunxa phantsi kwesenzo soxinzelelo lomoya, incedisa indawo enoxinzelelo oluphantsi embindini we-impeller. Ulwelo olukhawulezayo olukhutshwa kumda wangaphandle we-impeller lungena emzimbeni we-pump onemilo ye-volute, nto leyo eguqula ngakumbi amandla e-kinetic olwelo lube ngamandla oxinzelelo, ekugqibeleni ibangela ukuba i-slurry ikhutshwe kumbhobho wokukhupha ngoxinzelelo oluphezulu, ifezekise uthutho oluqhubekayo noluzinzileyo.

2, iingenelo eziphambili

1. Ukumelana nokukrala okukhulu

I-silicon carbide ngokwayo inobunzima obuphezulu kakhulu, ilandela idayimani kuphela ngobunzima be-Mohs. Oku kunciphisa kakhulu izinga lokuguguleka kwezixhobo zepompo ye-silicon carbide slurry xa ijongene ne-slurry equlethe inani elikhulu lamasuntswana aqinileyo. Xa kuthelekiswa neepompo ze-metal slurry zemveli, ubomi benkonzo yeepompo ze-silicon carbide slurry bunokwandiswa amaxesha amaninzi, kunciphisa ukuphindaphindeka kokutshintshwa nokugcinwa kwezixhobo, kunye nokuphucula ukuqhubeka kwemveliso kunye nokuzinza.

2. Ukumelana nokugqwala okugqwesileyo

I-silicon carbide izinzile kakuhle kwiikhemikhali kwaye inokumelana nokugqwala okuvela phantse kuzo zonke ii-asidi ezingaphiliyo, ii-asidi ze-organic, kunye neziseko. Kwezinye iikhemikhali, i-metallurgical, kunye nezinye iifektri, i-slag slurry idla ngokuba nokugqwala okunamandla. Ukusetyenziswa kweepompo ze-silicon carbide slurry kunokumelana ngempumelelo nokugqwala kwezinto zeekhemikhali, kuqinisekise ukusebenza okuqhelekileyo kwezixhobo, kwaye kuthintele iingozi zokhuseleko ezifana nokuvuza kunye nomonakalo wezixhobo obangelwa kukugqwala.

3. Uzinzo lobushushu obuphezulu

I-silicon carbide ikwanophawu lokuxhathisa amaqondo obushushu aphezulu, olunokumelana namaqondo obushushu afikelela kwi-1350 ℃. Kwezinye iimeko zoshishino ezinobushushu obuphezulu, ezifana nokuthuthwa kwe-slurry enobushushu obuphezulu, iimpompo ze-silicon carbide slurry zinokugcina ukusebenza okuzinzileyo kwaye aziyi kuguquka okanye zonakaliswe ngenxa yamaqondo obushushu aphezulu, zilungelelanise neendawo zokusebenza ezinzima.

3, Amasimi eSicelo

1. Ishishini lemigodi

Kwinkqubo yokwemba nokuphucula, kuyimfuneko ukuthutha isixa esikhulu se-slurry equlethe amasuntswana e-ore ahlukeneyo. La masuntswana awanalo nje kuphela uxinaniso oluphezulu, kodwa akwanalo nobunzima obuphezulu be-ore particles, nto leyo ebangela ukuguguleka okukhulu kwimpompo yokuhambisa. I-silicon carbide slurry pump, enokumelana nokuguguleka okugqwesileyo kunye nokumelana nokugqwala, inokuthutha i-slurry ngokufanelekileyo nangokuzinzileyo, iphucule ukusebenza kakuhle kwemveliso yemigodi, kwaye inciphise iindleko zokusebenza.

2. Ishishini lesinyithi

Imveliso yesinyithi ibandakanya ukuthuthwa kwezinto ezahlukeneyo zokunyibilikisa ezishushu kakhulu nezinobuthi obukhulu kunye ne-slag. Ipompo ye-silicon carbide slurry inokumelana nobushushu obuphezulu kwaye imelane nokubola kweekhemikhali, ihlangabezana neemfuno ezingqongqo zoshishino lwesinyithi zokuhambisa izixhobo kunye nokuqinisekisa inkqubela phambili ethe tye yenkqubo yemveliso.

3. Ishishini lamandla

Izityalo zamandla zivelisa inani elikhulu lentsalela yothuthu emva kokutshiswa kwamalahle, ekufuneka ithuthwe iye kwiindawo ezikhethiweyo ukuze icutshungulwe ngeempompo ze-slurry. Ipompo ye-slurry ye-silicon carbide inokukwazi ukumelana ngempumelelo nokuguguleka kothuthu, iqinisekise ukusebenza okuthembekileyo kwenkqubo yokuhambisa uthuthu, kwaye incede ekuvelisweni kwezityalo zamandla ezinobuhlobo nokusingqongileyo.

4. Ishishini leekhemikhali

Imveliso yeekhemikhali idla ngokudibana nolwelo olune-corrosive kunye ne-slurry equlethe amasuntswana aqinileyo. Ukumelana okuhle kakhulu nokugqwala kweepompo ze-silicon carbide slurry kuzenze zasetyenziswa kakhulu kwishishini leekhemikhali, okuqinisekisa ukhuseleko kunye nokuzinza kwemveliso yeekhemikhali.

Ipompo ye-silicon carbide slurry iye yaba sisixhobo esibalulekileyo sokuthutha izimboni ngenxa yomgaqo wayo okhethekileyo wokusebenza, iingenelo zokusebenza ezigqwesileyo, kunye neendawo ezininzi zokusetyenziswa. Ngophuhliso oluqhubekayo lwetekhnoloji yezimboni, iipompo ze-silicon carbide slurry nazo ziya kuqhubeka nokuvelisa izinto ezintsha nokuphucula, zibonelela ngesiqinisekiso esiqinileyo semveliso esebenzayo kumashishini ahlukeneyo.

Ixesha leposi: Julayi-12-2025