Muzviitiko zvakawanda zvekugadzirwa kwemaindasitiri, zvinowanzo fanirwa kutakura matope ane zvimedu zvakasimba, zvakaita semaminerari mumigodhi, madota mumafekitori emagetsi, uye zvinwiwa zvinonyungudutsa muindasitiri yesimbi. Mamatope aya ane ngura yakasimba uye anodzivirira kupfeka zvakanyanya, izvo zvinoda michina yekufambisa zvinhu zvakanyanya.pombi yesilicon carbide slurryyakabuda nekuda kwekuda uku uye yave musimboti webasa rekutakura zvinhu mumaindasitiri.

1, musimboti wekushanda

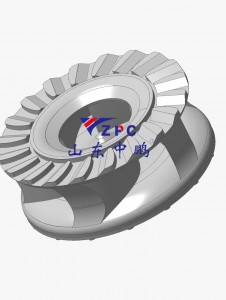

Pombi ye silicon carbide slurry inonyanya kushandiswa pakushanda kwemapombi e centrifugal. Kana mota ikafambisa pombi kuti itenderere nekumhanya kukuru, impeller yakabatana ne pombi inotendererawo nekumhanya kukuru. Mapazi ari pa impeller achasunda mvura yakapoteredza kuti itenderere pamwe chete. Pasi pesimba re centrifugal, mvura inokandwa kubva pakati pe impeller kuenda kumucheto wekunze, uye kumhanya nekumanikidzwa zvese zvinowedzera. Panguva iyi, nzvimbo ine kumanikidzwa kwakaderera inoumbwa pakati pe impeller, uye slurry yekunze inopinda mumuviri we pombi kuburikidza nepombi yekusveta pasi pesimba remhepo, ichiwedzera nzvimbo ine kumanikidzwa kwakaderera pakati pe impeller. Mvura inomhanyisa inoburitswa kubva kumucheto wekunze we impeller inopinda mumuviri we pombi wakaita se volute, izvo zvinoshandura simba re kinetic remvura kuita simba rekumanikidzwa, zvichizoita kuti slurry ibudiswe kubva pa pombi yekuburitsa nekumanikidzwa kwakakwira, zvichiita kuti kutakurwa kurambe kwakasimba.

2, zvakanakira zvepakati

1. Kudzivirira kukuru kwekukuvara

Silicon carbide pachayo ine kuomarara kwakanyanya, yechipiri kune dhaimani kana tichitarisa kuomarara kweMohs. Izvi zvinoderedza zvakanyanya kupera kwezvikamu zvinoyerera zvepombi yeslurry yesilicon carbide kana yakatarisana neslurry ine huwandu hwakawanda hwezvimedu zvakaoma. Zvichienzaniswa nemapombi esimbi ekare, hupenyu hwepombi dzeslurry dzesilicon carbide hunogona kuwedzerwa kakawanda, zvichideredza kuwanda kwekutsiviwa nekugadzirisa michina, uye kuvandudza kuenderera mberi kwekugadzirwa uye kugadzikana.

2. Kudzivirira ngura kwakanyanya

Silicon carbide ine kugadzikana kwakanaka kwemakemikari uye inogona kutsungirira ngura kubva kuma inorganic acids ese, organic acids, uye mabhesi. Mune mamwe maindasitiri emakemikari, metallurgical, uye mamwe, slag slurry inowanzova nengura yakasimba. Kushandiswa kwemapombi e silicon carbide slurry kunogona kudzivirira zvinobudirira kuparadzwa kwezvinhu zvemakemikari, kuve nechokwadi chekushanda zvakanaka kwemidziyo, uye kudzivirira njodzi dzekuchengetedza dzakadai sekubuda kwemvura uye kukuvara kwemidziyo kunokonzerwa nengura.

3. Kugadzikana kwekupisa kwakanyanya

Silicon carbide ine hunhu hwekudzivirira kupisa kwakanyanya, iyo inogona kutsungirira kupisa kusvika 1350 ℃. Mune mamwe mamiriro eindasitiri anodziya zvakanyanya, akadai sekutakurwa kweslurry inodziya zvakanyanya, mapombi eslurry esilicon carbide anogona kuchengetedza kushanda kwakasimba uye haazokanganise kana kukuvara nekuda kwekupisa kwakanyanya, achichinjika kunzvimbo dzekushanda dzakaoma.

3, Minda yeKushandisa

1. Indasitiri yemigodhi

Mukuita kwekuchera nekugadzira, zvinodikanwa kutakura huwandu hwakawanda hwetsvina ine zvidimbu zvakasiyana-siyana zvematombo. Matsvina aya haana kungova nehuwandu hwakawanda chete, asiwo ane kuomarara kwakanyanya kwezvikamu zvematombo, izvo zvinokonzera kupera kwakanyanya papombi yekutakura. Pombi yeslurry yesilicon carbide, ine simba rayo rakanaka rekudzivirira kupera uye kuramba ngura, inogona kutakura slurry zvakanaka uye zvakadzikama, kuvandudza kushanda zvakanaka kwekugadzira migodi, uye kuderedza mari yekushanda.

2. Indasitiri yesimbi

Kugadzirwa kwesimbi kunosanganisira kutakurwa kwemhando dzakasiyana-siyana dzezvinwiwa zvinonyungudutsa zvinopisa zvakanyanya uye zvinoparadza zvakanyanya. Pombi yesimbi yesilicon carbide inogona kutsungirira kupisa kwakanyanya uye kuramba ngura yemakemikari, ichizadzisa zvinodiwa neindasitiri yesimbi yekufambisa michina uye kuona kufambira mberi kwakanaka kwemaitiro ekugadzira.

3. Indasitiri yemagetsi

Zvivakwa zvemagetsi zvinogadzira huwandu hwakawanda hwemadota mushure mekupiswa kwemarasha, ayo anoda kutakurwa kuenda kunzvimbo dzakatarwa kuti agadziriswe kuburikidza nemapombi eslurry. Pombi yeslurry yesilicon carbide inogona kubata nekusakara kwedota, kuve nechokwadi chekuti sisitimu yekutakura madota inoshanda zvakanaka, uye kubatsira mukugadzirwa kwezvivakwa zvemagetsi zvisina njodzi kune zvakatipoteredza.

4. Indasitiri yemakemikari

Kugadzirwa kwemakemikari kunowanzo sangana nezvinwiwa zvakasiyana-siyana zvinoparadza zvakanyanya uye slurry dzine zvidimbu zvakasimba. Kusagadzikana kwakanaka kwe corrosion kwe silicon carbide slurry pombi kwakaita kuti zvishandiswe zvakanyanya muindasitiri yemakemikari, zvichiita kuti kugadzirwa kwemakemikari kuve kwakachengeteka uye kwakasimba.

Pombi yesilicon carbide slurry yave chinhu chakakosha pakufambisa maindasitiri nekuda kwekushanda kwayo kwakasiyana, mabhenefiti ayo akanaka, uye nzvimbo dzakasiyana dzekushandisa. Nekuvandudzwa kuri kuramba kuchiitwa kwetekinoroji yeindasitiri, pombi dzesilicon carbide slurry dzicharamba dzichigadzira zvinhu zvitsva uye dzichivandudza, zvichipa vimbiso yakasimba yekugadzira zvinobudirira mumaindasitiri akasiyana-siyana.

Nguva yekutumira: Chikunguru-12-2025