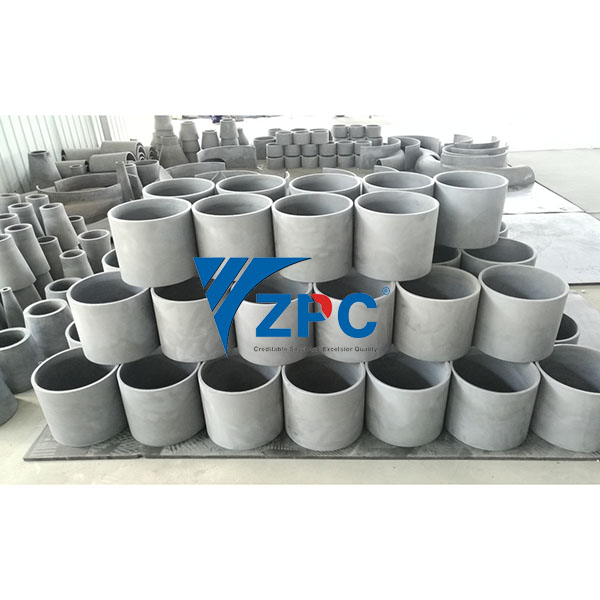

I-busher/bushing yokumelana nokuguguleka kanye nokuguguleka

I-silicon carbide ceramic bushing inokuqina okuphezulu, ukuhanjiswa kokushisa okuhle kakhulu, ukumelana nokuguguleka, ukushaqeka, ukugqwala kanye nokushisa okuphezulu, kanye nokuphila isikhathi eside kwe-polyurethane okuphindwe kasithupha. Isetshenziswa ikakhulukazi ekulinganisweni, ekugxilweni nasekuphelelweni kwamanzi kwama-granule agqwalayo nama-coarse embonini yokugqoka i-ore, i-petroleum, ukongiwa kwamanzi, amalahle, njll.

Ipayipi elimelana nokuguguleka kwe-silicon carbide ceramic likhiqizwa ngokufaka ipayipi le-ceramic elicwebezelayo ngaphakathi kwepayipi lensimbi nge-glue (ikakhulukazi i-polyurethane). Ukubopha phakathi kwe-ceramic nepayipi lensimbi kuqinile futhi kuncane, kukwazi ukumelana nokushisa kusuka ku--50℃ kuya ku-1350℃. I-ceramic lining inokuqina okuphezulu, ukuguguleka kanye nokukhuthazela komthelela, ukumelana nokugqwala, indawo ebushelelezi, kanye nokumelana nothuli. Ubukhulu bayo buyahlukahluka kusuka ku-6 kuya ku-25 mm. Ifanele ukuhlukaniswa, ukuhlushwa, ukuphelelwa amanzi emzimbeni kwezinhlayiya ezigqwalile neziqinile. Njengamanje, isetshenziswe kabanzi ekucubungulweni kwamaminerali, emisebenzini yokunisela, kanye nasezimbonini zamandla kagesi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.