In the industrial field, transporting liquids containing solid particles is a common but highly challenging task, such as transporting slurry in mining and transporting ash in thermal power generation. The slurry pump plays a crucial role in completing this task. Among numerous slurry pumps, silicon carbide impeller slurry pumps are gradually becoming a reliable assistant for industrial transportation due to their unique advantages.

The impeller of ordinary slurry pumps is often made of metal materials. Although metal materials have certain strength and toughness, they are easily worn and corroded when facing liquids with corrosive and high hardness particles. For example, in some chemical enterprises, the transported liquid contains acidic substances, and ordinary metal impellers may quickly corrode, leading to a decrease in pump performance and frequent replacement of impellers, which not only affects production efficiency but also increases costs.

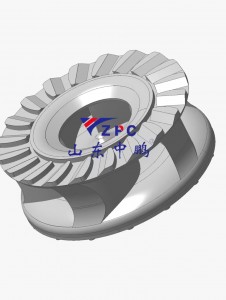

Silicon carbide impeller slurry pump is different, its “secret weapon” is silicon carbide material. Silicon carbide is an excellent ceramic material with ultra-high hardness, second only to the hardest diamond in nature. This means that when a liquid containing hard particles impacts the impeller at high speed, the silicon carbide impeller can effectively resist wear and greatly extend its service life.

Meanwhile, the chemical properties of silicon carbide are very stable and can withstand various types of corrosion. In some industries that require the transportation of corrosive liquids, such as electroplating, chemical industry, etc., silicon carbide impeller slurry pumps can easily cope with it, avoiding the problem of corrosion of ordinary metal impellers and ensuring the stable operation of the pump.

In addition to wear and corrosion resistance, silicon carbide also has good thermal conductivity. During the operation of the pump, the high-speed rotation of the impeller generates heat, and silicon carbide can quickly dissipate the heat to prevent damage to the impeller due to high temperature, further improving the reliability of the pump.

In practical applications, silicon carbide impeller slurry pumps have also demonstrated significant advantages. For example, in the mining industry, when using ordinary slurry pumps, the impeller may need to be replaced every few months. However, with the use of silicon carbide impeller slurry pumps, the replacement cycle of the impeller can be extended to one year or even longer, greatly reducing equipment maintenance time and costs, and improving production efficiency.

Although silicon carbide impeller slurry pump has many advantages, it is not perfect. Due to the brittleness of silicon carbide materials, they may experience cracking when subjected to sudden impact forces. However, with the continuous advancement of technology, engineers are also improving through various methods, such as optimizing the design structure of the impeller to better distribute stress and reduce the risk of rupture.

I believe that in the future, with the continuous development of materials science and manufacturing technology, the performance of silicon carbide impeller slurry pumps will be more perfect, and their applications will be more extensive, bringing more convenience and benefits to the industrial transportation field.

Post time: Jun-27-2025