Emkhakheni wezimboni, ukuthutha uketshezi oluqukethe izinhlayiya eziqinile kuwumsebenzi ovamile kodwa onzima kakhulu, njengokuthutha udaka ezimayini kanye nokuthutha umlotha ekukhiqizeni amandla okushisa. Iphampu yedaka idlala indima ebalulekile ekuqedeni lo msebenzi. Phakathi kwamaphampu amaningi edaka,amaphampu e-silicon carbide impeller slurrykancane kancane ziba umsizi othembekile wezokuthutha zezimboni ngenxa yezinzuzo zazo eziyingqayizivele.

I-impeller yamaphampu avamile odaka ivame ukwenziwa ngezinto zensimbi. Nakuba izinto zensimbi zinamandla athile nokuqina, ziguga kalula futhi zigqwale lapho zibhekene noketshezi olunezinhlayiya ezigqwalisayo nezinobunzima obukhulu. Isibonelo, kwamanye amabhizinisi amakhemikhali, uketshezi oluthuthwayo luqukethe izinto ezinobuthi, futhi ama-impeller ensimbi avamile angagqwala ngokushesha, okuholela ekunciphiseni ukusebenza kwephampu kanye nokushintsha njalo kwama-impeller, okungagcini nje ngokuphazamisa ukusebenza kahle kokukhiqiza kodwa futhi kwandisa nezindleko.

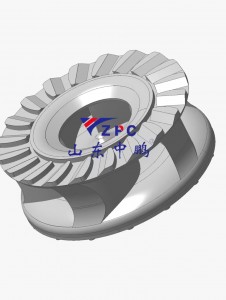

Iphampu yodaka lwe-silicon carbide impeller ihlukile, "isikhali sayo esiyimfihlo" yizinto ze-silicon carbide. I-Silicon carbide iyinto enhle kakhulu ye-ceramic enobunzima obuphezulu kakhulu, eyesibili kuphela kunedayimane elinzima kakhulu ngokwemvelo. Lokhu kusho ukuthi lapho uketshezi oluqukethe izinhlayiya eziqinile luthinta i-impeller ngesivinini esikhulu, i-impeller ye-silicon carbide ingamelana ngempumelelo nokuguguleka futhi yandise kakhulu isikhathi sayo sokusebenza.

Okwamanje, izakhiwo zamakhemikhali ze-silicon carbide zizinzile kakhulu futhi zingamelana nezinhlobo ezahlukene zokugqwala. Kwezinye izimboni ezidinga ukuthuthwa koketshezi olugqwala, njenge-electroplating, imboni yamakhemikhali, njll., amaphampu e-silicon carbide impeller slurry angabhekana nakho kalula, agweme inkinga yokugqwala kwama-impeller ensimbi ajwayelekile futhi aqinisekise ukusebenza okuzinzile kwephampu.

Ngaphezu kokumelana nokuguguleka nokugqwala, i-silicon carbide nayo inomoya omuhle wokushisa. Ngesikhathi sokusebenza kwephampu, ukujikeleza kwesivinini esikhulu se-impeller kukhiqiza ukushisa, futhi i-silicon carbide ingasusa ukushisa ngokushesha ukuvimbela umonakalo ku-impeller ngenxa yokushisa okuphezulu, okuthuthukisa kakhulu ukuthembeka kwephampu.

Ezisetshenzisweni ezisebenzayo, amaphampu e-silicon carbide impeller slurry nawo abonise izinzuzo ezibalulekile. Isibonelo, embonini yezimayini, uma kusetshenziswa amaphampu ajwayelekile e-slurry, i-impeller ingadinga ukushintshwa njalo ezinyangeni ezimbalwa. Kodwa-ke, ngokusebenzisa amaphampu e-silicon carbide impeller slurry, umjikelezo wokufaka esikhundleni se-impeller ungandiswa ube unyaka owodwa noma ngaphezulu, okunciphisa kakhulu isikhathi sokulungisa imishini kanye nezindleko, futhi kuthuthukiswe ukusebenza kahle kokukhiqiza.

Nakuba ipompo ye-silicon carbide impeller slurry inezinzuzo eziningi, ayiphelele. Ngenxa yobuthakathaka bezinto ze-silicon carbide, zingase ziqhekeke lapho zibhekene namandla okushaywa ngokuzumayo. Kodwa-ke, ngokuthuthuka okuqhubekayo kobuchwepheshe, onjiniyela nabo bayathuthuka ngezindlela ezahlukene, njengokuthuthukisa isakhiwo somklamo we-impeller ukuze kusatshalaliswe kangcono ukucindezeleka futhi kuncishiswe ingozi yokuqhekeka.

Ngikholwa ukuthi esikhathini esizayo, ngentuthuko eqhubekayo yesayensi yezinto zokwakha kanye nobuchwepheshe bokukhiqiza, ukusebenza kwamaphampu e-silicon carbide impeller slurry kuzoba okuphelele kakhulu, futhi ukusetshenziswa kwawo kuzoba kukhulu kakhulu, okuletha ukulula kanye nezinzuzo ezengeziwe emkhakheni wezokuthutha wezimboni.

Isikhathi sokuthunyelwe: Juni-27-2025