Dhinaca warshadaha, rarista dareerayaasha ka kooban walxaha adag waa hawl caadi ah laakiin aad u adag, sida rarista slurry-ka macdan qodista iyo rarista dambaska marka la samaynayo korontada kulaylka. Bamka slurry-ku wuxuu door muhiim ah ka ciyaaraa dhammaystirka hawshan. Bamka slurry-ka ee badan,bambooyin slurry impeller silicon carbidewaxay si tartiib tartiib ah u noqonayaan kaaliye lagu kalsoonaan karo oo loogu talagalay gaadiidka warshadaha sababtoo ah faa'iidooyinkooda gaarka ah.

Qalabka lagu shubo bamka slurry-ka caadiga ah badanaa waxaa laga sameeyaa walxo bir ah. In kasta oo walxaha birtu ay leeyihiin xoog iyo adkaysi gaar ah, haddana si fudud ayaa loo duugaa oo loo miiro marka la wajaho dareereyaal leh walxo daxal leh oo adag. Tusaale ahaan, shirkadaha kiimikada qaarkood, dareeraha la qaadayo wuxuu ka kooban yahay walxo aashito leh, qalabka lagu shubo biraha caadiga ahna si dhakhso ah ayuu u miiro, taasoo keenta hoos u dhac ku yimaada waxqabadka bamka iyo beddelka joogtada ah ee qalabka lagu shubo, taas oo aan saameyn ku yeelan oo keliya waxtarka wax soo saarka laakiin sidoo kale kordhisa kharashyada.

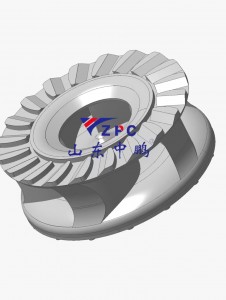

Bamka slurry-ka ee Silicon carbide-ka waa ka duwan yahay, "hubka qarsoon" waa walax carbide silicon ah. Silicon carbide waa walax dhoobo ah oo aad u fiican oo leh adkeysi aad u sarreeya, oo ka dambeysa kaliya dheemanka ugu adag ee dabiiciga ah. Taas macnaheedu waa marka dareere ka kooban walxo adag uu saameeyo impeller-ka xawaare sare, impeller-ka silicon carbide-ka wuxuu si wax ku ool ah u iska caabin karaa xirashada wuxuuna si weyn u dheereyn karaa cimrigiisa adeegga.

Dhanka kale, sifooyinka kiimikada ee carbide-ka silicon aad bay u deggan yihiin waxayna u adkeysan karaan noocyada kala duwan ee daxalka. Warshadaha qaarkood ee u baahan gaadiidka dareerayaasha daxalka ah, sida electroplating, warshadaha kiimikada, iwm., bambooyin slurry ah oo silicon carbide ah ayaa si fudud ula qabsan kara, iyagoo ka fogaanaya dhibaatada daxalka ee impellers-ka birta caadiga ah iyo hubinta hawlgalka xasilloon ee bamka.

Marka laga soo tago xirashada iyo iska caabbinta daxalka, carbide-ka silicon wuxuu kaloo leeyahay hab-socod kuleyl oo wanaagsan. Inta lagu jiro hawlgalka bamka, wareegga xawaaraha sare ee impeller-ku wuxuu dhaliyaa kuleyl, carbide-ka silicon-kuna si dhakhso ah ayuu u baabi'in karaa kulaylka si looga hortago waxyeelada impeller-ka sababtoo ah heerkulka sare, taasoo sii wanaajinaysa isku halaynta bamka.

Codsiyada wax ku oolka ah, bambooyinka slurry-ka ee silicon carbide-ka ayaa sidoo kale muujiyay faa'iidooyin muhiim ah. Tusaale ahaan, warshadaha macdanta, marka la isticmaalayo bambooyinka slurry-ka caadiga ah, impeller-ka waxaa laga yaabaa in loo baahdo in la beddelo dhowrkii biloodba mar. Si kastaba ha ahaatee, iyadoo la adeegsanayo bambooyinka slurry-ka ee silicon carbide-ka, wareegga beddelka ee impeller-ka waxaa loo kordhin karaa hal sano ama ka badan, taasoo si weyn u yareyneysa waqtiga dayactirka qalabka iyo kharashyada, iyo hagaajinta hufnaanta wax soo saarka.

In kasta oo bamka silikoon carbide ee slurry-ka uu leeyahay faa'iidooyin badan, haddana ma aha mid qumman. Sababtoo ah jilicsanaanta walxaha silikoon carbide, waxay la kulmi karaan dildilaac marka ay la kulmaan xoogagga saamaynta degdegga ah. Si kastaba ha ahaatee, iyadoo la raacayo horumarka joogtada ah ee tignoolajiyada, injineeradu waxay sidoo kale horumarinayaan habab kala duwan, sida hagaajinta qaab-dhismeedka naqshadeynta si loo qaybiyo cadaadiska si wanaagsan loona yareeyo khatarta dillaaca.

Waxaan aaminsanahay in mustaqbalka, iyadoo la raacayo horumarinta joogtada ah ee sayniska agabka iyo tignoolajiyada wax soo saarka, waxqabadka bambooyinka slurry-ka ee silicon carbide-ka ayaa noqon doona mid aad u qumman, codsigooduna uu noqon doono mid aad u ballaaran, taasoo u keenaysa raaxo iyo faa'iidooyin badan goobta gaadiidka warshadaha.

Waqtiga boostada: Juun-27-2025