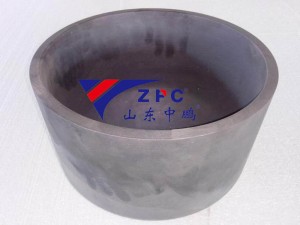

I-silicon carbide eboshiwe yokusabelaizitsha zomliloimelela intuthuko kwezobuchwepheshe obungaguquki, inikeza ukusebenza okungenakuqhathaniswa ezindaweni ezishisayo kakhulu. Lezi zitsha ze-ceramic ezithuthukisiwe sezibe yinto ebalulekile kuzo zonke izimboni ze-metallurgy, i-precision casting, i-mechanical engineering, kanye ne-chemical processing, ziletha ukusebenza okuphezulu lapho izinto zendabuko zingaphumeleli khona.

Izinzuzo Zobuchwepheshe Eziyinhloko

Ama-crucible e-RBSC asebenza kahle kakhulu kune-alumina evamile kanye ne-graphite ngokusebenzisa:

- Ukushisa okungavamile (120–150 W/m·K ku-1000°C)

- I-coefficient yokwandisa ukushisa ephansi kakhulu (4.5×10⁻⁶/K)

- Ukumelana nokushaqeka kokushisa okubekezelela imijikelezo yokupholisa okusheshayo engaphezu kuka-50 (1600°C →25°C)

- Ukumelana nokugqwala kwe-asidi/alkali (ukuhambisana kwe-pH 0–14)

- Ukuqina kwe-oxidation emoyeni kufika ku-1650°C

Ubuchwepheshe Bensimbi

Ekukhiqizweni kwensimbi ye-alloy kanye nokuncibilikisa insimbi engeyona i-ferrous (i-aluminium, ithusi, i-zinc), izitsha ze-RBSC zivumela:

- amazinga okuncibilika asheshayo angu-20–30% ngokudluliselwa kokushisa okuhle

- Ukulungiswa kobumsulwa bensimbi okungu-99.95% ngokusebenzisa izindawo ezingaphenduli

- Ukwakheka kwe-slag okuncishisiwe ngokunciphisa ukuhlukaniswa kokushisa

- Isikhathi senkonzo esandisiwe (3–5× isikhathi eside kunezitsha zobumba-i-graphite)

Izicelo Zokuphonsa Ngokuqondile Nezomshini

Izakhiwo ezihlukile zemishini yezikebhe zisekela izidingo zezimboni ezidingayo:

- Ukuqina kwesakhiwo okuhlala isikhathi eside ngaphansi kokucindezeleka komshini okungu-15–20 MPa

- Ukuqina kobukhulu obuhambisanayo (±0.1% ushintsho lwevolumu ku-1500°C)

- Ukucutshungulwa okungenakho ukungcola kwezingxenye zezinga lezindiza

- Ukusebenza okuthembekile ezinhlelweni zokusakaza ze-centrifugal

Ubuhle Bokucubungula Amakhemikhali

Izitsha ze-RBSC zibhekana nezinselele ezibalulekile ekuhlanganisweni kwamakhemikhali:

- Ukugcinwa okuphephile kosawoti oncibilikisiwe (isb., NaOH, KNO₃)

- Ukusebenza okuzinzile ekuphenduleni kwe-sulfidation/chlorination

- Ukumelana nokugqwala ngokumelene ne-HF kufika ku-800°C

- Ukulondolozwa kobumsulwa ekukhishweni kwezinto ezingavamile zomhlaba

Ezomnotho Zokusebenza

Nakuba izindleko zokuqala ziphakeme ngo-40-60% kunezitsha zokubhaka zendabuko, izixazululo ze-RBSC ziletha:

- Ukwehla okungu-70% kwemvamisa yokushintsha

- Ukonga amandla okungu-25–35% ngokusebenzisa ukusebenza kahle kokushisa okuthuthukisiwe

- Ukuphinda kusetshenziswe izinto ezingu-90% ngokuvuselelwa kokushisa

- Izidingo zokulungisa ezicishe zibe yi-zero

Ukuqamba Okukhethekile Kwemboni

1. Ukukhiqizwa kwe-Titanium Alloy

- Imelana nokuncibilika kwe-Ti ephendulayo ku-1700°C

- Kuvimbela ukungcoliswa kokuqoqwa kwekhabhoni

2. Ukwenziwa Kwezinto Zebhethri

- Ivumela ukucutshungulwa kwe-cathode ye-LiCoO₂ efanayo

- Iyamelana nokugqwala kwe-lithium salt

3. Ukukhula Kwekristalu Le-semiconductor

- Igcina ukuhambisana okuphezulu kakhulu kwe-vacuum

- Kuqeda ukungcoliswa kwe-silicon carbide

Umklamo Wesikhathi Esizayo

Izitsha ze-RBSC zesimanje zifaka izici ezithuthukisiwe:

- Izakhiwo ze-gradient porosity zokulawula ukungena kwegesi

- Izimbozo zomphezulu ze-Nanoscale ezithuthukisa ukumelana ne-slag

- Izinzwa zokushisa ezifakiwe zokuqapha inqubo

Kusukela ocwaningweni lwelabhorethri kuya ekukhiqizweni kwezimboni, izitsha zokubhaka ze-silicon carbide eziboshwe yi-reaction-bond ziyaqhubeka nokuchaza kabusha amakhono okucubungula ukushisa. Inhlanganisela yazo eyingqayizivele yezakhiwo zokushisa, zemishini, nezamakhemikhali izibeka njengezitsha zokubhaka ezikhethwayo zezinhlelo zokusebenza zokushisa okuphezulu zesizukulwane esilandelayo, okuqhuba ukusebenza kahle kanye nokuthuthukiswa kwekhwalithi emikhakheni eminingi yokukhiqiza ethuthukisiwe.

Isikhathi sokuthunyelwe: Mashi-20-2025