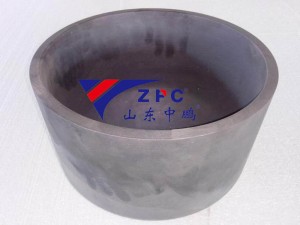

Reaction-bonded silicon carbidebututun ruwasuna wakiltar wani ci gaba a fasahar da ke hana ruwa gudu, wanda ke ba da aiki mara misaltuwa a cikin yanayin zafi mai tsanani. Waɗannan kwantena na yumbu masu ci gaba sun zama dole a cikin masana'antar ƙarfe, simintin daidai, injiniyan injiniya, da masana'antar sarrafa sinadarai, suna ba da ingantaccen aiki inda kayan gargajiya ba su da inganci.

Amfanin Fasaha na Core

RBSC crucibles sun fi takwarorin alumina da graphite na gargajiya kyau ta hanyar:

- Ƙarfin watsa zafi na musamman (120–150 W/m·K a 1000°C)

- Ma'aunin faɗaɗa zafi mai ƙarancin ƙarfi (4.5×10⁻⁶/K)

- Juriyar girgiza mai zafi da ke jure wa zagayowar sanyaya mai sauri sama da 50 (1600°C →25°C)

- Juriyar tsatsa ta acid/alkali (daidaitawar pH 0–14)

- Daidaiton iskar oxygen a cikin iska har zuwa 1650°C

Ƙwarewar Ƙarfe

A cikin samar da ƙarfe mai ƙarfe da kuma narkewar ƙarfe mara ƙarfe (aluminum, jan ƙarfe, zinc), RBSC crucibles suna ba da damar:

- 20-30% saurin narkewar abinci ta hanyar ingantaccen canja wurin zafi

- Kula da tsarkin ƙarfe kashi 99.95% ta hanyar saman da ba ya amsawa

- Rage samuwar slag ta hanyar rage rarrabuwar zafi

- Tsawon rai na aiki (3-5 × fiye da na'urorin yumbu-graphite)

Daidaitaccen Simintin Gyara & Aikace-aikacen Inji

Sifofin injina na musamman na crucibles suna tallafawa buƙatun masana'antu masu wahala:

- Ingantaccen tsarin aiki a ƙarƙashin matsin lamba na inji na 15-20 MPa

- Daidaitaccen daidaiton girma (±0.1% canjin girma a 1500°C)

- Tsarin sarrafawa mara gurɓatawa ga abubuwan da aka haɗa a fannin sararin samaniya

- Ingantaccen aiki a cikin tsarin simintin centrifugal

Ingantaccen Sarrafa Sinadarai

RBSC crucibles suna magance manyan ƙalubale a cikin haɗakar sinadarai:

- Gishirin da aka narke cikin aminci (misali, NaOH, KNO₃)

- Aiki mai dorewa a cikin halayen sulfidation/chlorination

- Juriyar tsatsa a kan HF har zuwa 800°C

- Tsarkakewa a cikin cire abubuwan ƙasa masu wuya

Tattalin Arzikin Aiki

Duk da cewa farashin farko ya fi kashi 40-60% sama da na gargajiya, hanyoyin RBSC suna bayarwa:

- Rage yawan maye gurbin kashi 70%

- Kashi 25-35% na tanadin makamashi ta hanyar ingantaccen ingancin zafi

- Kashi 90% na sake amfani da kayan ta hanyar sake amfani da zafi

- Kusan babu buƙatun kulawa

Sabbin Sabbin Abubuwa na Musamman a Masana'antu

1. Samar da Alloy na Titanium

- Yana jure wa zafin da Ti ke narkewa a 1700°C

- Yana hana gurɓatar iskar carbon

2. Haɗa Kayan Baturi

- Yana ba da damar sarrafa cathode na LiCoO₂ iri ɗaya

- Yana jure tsatsawar gishirin lithium

3. Girman Crystal na Semiconductor

- Yana kula da daidaiton injin mai ƙarfi sosai

- Yana kawar da gurɓatar silicon carbide

Tsarin Gaba-gaba

Gilashin RBSC na zamani sun haɗa da fasaloli masu kyau:

- Tsarin porosity na gradient don sarrafa iskar gas

- Rufin saman Nanoscale yana ƙara juriya ga slag

- Na'urori masu auna zafi da aka saka don sa ido kan tsari

Daga binciken da aka yi a dakin gwaje-gwaje zuwa samar da kayan masana'antu, ƙwayoyin silicon carbide masu haɗin kai suna ci gaba da sake fasalta ƙarfin sarrafa zafi. Haɗinsu na musamman na halayen zafi, na inji, da na sinadarai yana sanya su a matsayin abin da ake so don amfani da su a cikin yanayi mai zafi mai girma na gaba, wanda ke haifar da inganci da haɓaka inganci a fannoni daban-daban na masana'antu.

Lokacin Saƙo: Maris-20-2025