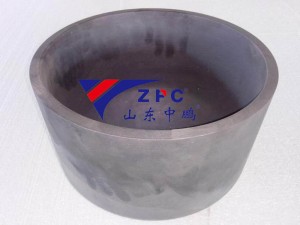

Reaction yakabatana nesilicon carbidezviyo zvemotoinomiririra budiriro mu tekinoroji yekusagadzirisa zvinhu, ichipa mashandiro asina muganho munzvimbo dzinopisa zvakanyanya. Matangi aya epamusoro-soro eceramic ave akakosha muindasitiri dzesimbi, kugadzira zvinhu nemazvo, mainjiniya emakanika, uye makemikari, zvichipa mashandiro epamusoro apo zvinhu zvechinyakare hazvishande zvakanaka.

Zvakanakira zveUnyanzvi hwepakati

Zvigadziko zveRBSC zvinoshanda kupfuura zvimwe zvinhu zvemazuva ano zvealumina negraphite kuburikidza ne:

- Kufambisa kwekupisa kunoshamisa (120–150 W/m·K pa1000°C)

- Kuwedzerwa kwemafuta kwakaderera zvakanyanya (4.5×10⁻⁶/K)

- Kudzivirira kupisa kunopisa kunopfuura 50+ kutonhora nekukurumidza (1600°C →25°C)

- Kudzivirira ngura yeasidhi/alkali (pH 0–14 inoenderana)

- Kugadzikana kwe oxidation mumhepo kusvika 1650°C

Unyanzvi hweMetallurgical

Mukugadzirwa kwesimbi ye alloy uye kunyungudutsa simbi isina ferrous (aluminium, copper, zinc), RBSC crucibles inogonesa:

- 20–30% kukurumidza kunyunguduka kuburikidza nekupisa kwakagadziridzwa

- Kugadziriswa kwe99.95% kuchena kwesimbi kuburikidza nenzvimbo dzisingashande

- Kuderedza kuumbwa kwetsvina kuburikidza nekudzikiswa kwekupatsanurwa kwekupisa

- Nguva yakareba yekushanda (3–5× yakareba kupfuura zvimiti zvevhu-graphite)

Kushandiswa Kwekugadzira Nekugadzira Nekugadzira Machinical

Zvimiro zvemakanika zvakasiyana zvezviputi zvinotsigira zvinodiwa zvemaindasitiri:

- Kusimba kwechimiro kwakasimba pasi pesimba re15–20 MPa

- Kugadzikana kwakaenzana kwezvikamu (± 0.1% shanduko yevhoriyamu pa1500°C)

- Kugadziriswa kusina kusvibiswa kwezvinhu zvemuchadenga

- Kushanda kwakavimbika muhurongwa hwekukanda hwe centrifugal

Kugona Kugadzira Makemikari

Zvigadziko zveRBSC zvinogadzirisa matambudziko akakosha mukugadzirwa kwemakemikari:

- Kuchengetedza munyu wakanyungudutswa zvakachengeteka (semuenzaniso, NaOH, KNO₃)

- Kushanda kwakasimba mukuita kwe sulfidation/chlorination

- Kuramba ngura pakupisa kweHF kusvika 800°C

- Kuchengetedzwa kwehutsanana mukubviswa kwezvinhu zverare earth

Zvehupfumi Zvinoshanda

Kunyange zvazvo mitengo yekutanga yakakwira ne40-60% kupfuura zvigadziko zvechinyakare, mhinduro dzeRBSC dzinopa:

- Kuderedzwa kwe70% mukutsiviwa kwehuwandu

- Kuchengetedza simba ne25–35% kuburikidza nekuvandudza kushanda zvakanaka kwekupisa

- 90% inogona kushandiswazve kuburikidza nekupisa

- Zvinodiwa zvekugadzirisa zviri pedyo nezero

Zvitsva Zvakasiyana Neindasitiri

1. Kugadzirwa kweTitanium Alloy

- Inotsungirira kunyunguduka kweTi inonyunguduka pa1700°C

- Inodzivirira kusvibiswa kwekabhoni

2. Kugadzirwa kwezvinhu zvebhatiri

- Inogonesa LiCoO₂ cathode processing yakafanana

- Inodzivirira ngura yemunyu we lithium

3. Kukura kweCrystal yeSemiconductor

- Inochengetedza kuenderana kwevacuum kwakanyanya

- Inobvisa kusvibiswa kwesilicon carbide

Dhizaini Yeramangwana

Zvigadziko zveRBSC zvemazuva ano zvinosanganisira zvinhu zvepamusoro:

- Zvivako zve gradient porosity zvekugadzirisa gasi rinodzorwa

- Kupfeka kwepamusoro kweNanoscale kunowedzera kuramba kwetsvina

- Ma sensor ekupisa akabatanidzwa ekutarisa maitiro

Kubva pakutsvagurudza kwakakura murabhoritari kusvika pakugadzirwa kwezvinhu zvakawanda mumaindasitiri, zvigadziko zvesilicon carbide zvine reactive-bonded zvinoramba zvichitsanangura patsva kugona kwekupisa. Musanganiswa wazvo wehunhu hwekupisa, hwemakanika, uye hwemakemikari zvinozviisa panzvimbo yekusarudzirwa kwekushandiswa kwekupisa kwakanyanya muchizvarwa chinotevera, zvichikurudzira kushanda zvakanaka uye kuvandudzwa kwemhando yepamusoro muzvikamu zvakawanda zvekugadzira zvepamberi.

Nguva yekutumira: Kurume-20-2025