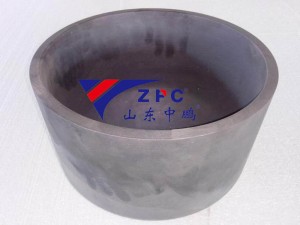

Kaarboohaydraytka Silicon ee ku xidhan falcelintasaqafyadawaxay matalaan horumar laga sameeyay tignoolajiyada iska caabbinta, iyagoo bixinaya waxqabad aan la barbar dhigi karin oo ka jira jawi kuleyl aad u daran. Weelashan dhoobada ah ee horumarsan waxay noqdeen kuwo aan lagama maarmaan u ah warshadaha birta, shubka saxda ah, injineernimada farsamada, iyo warshadaha wax soo saarka kiimikada, iyagoo bixinaya shaqo heer sare ah halkaasoo agabka dhaqameedku uu gaaban yahay.

Faa'iidooyinka Farsamada ee Muhiimka ah

Qalabka RBSC crucibles wuxuu ka fiican yahay kuwa caadiga ah ee aluminium iyo graphite iyada oo loo marayo:

- Daawaynta kulaylka oo heer sare ah (120–150 W/m·K at 1000°C)

- Isku-darka ballaarinta kulaylka aadka u hooseeya (4.5×10⁻⁶/K)

- Iska caabbinta shoogga kulaylka oo u adkaysata wareegyada qaboojinta degdega ah ee 50+ (1600°C →25°C)

- Iska caabbinta daxalka aashitada/alkali (isku-waafajinta pH 0–14)

- Xasiloonida oksaydhka hawada ilaa 1650°C

Aqoonta Birta

Wax soo saarka birta daawaha iyo dhalaalinta birta aan birta ahayn (aluminium, copper, zinc), RBSC crucibles waxay awood u leeyihiin:

- 20-30% heerarka dhalaalka si dhakhso leh iyada oo loo marayo wareejinta kulaylka ee la hagaajiyay

- 99.95% dayactirka nadiifinta birta iyada oo loo marayo dusha sare ee aan falcelinta lahayn

- Yaraynta sameynta slag iyada oo loo marayo kala-soocid kuleyl oo yar

- Cimri adeeg oo dheer (3-5 × ka dheer dhoobada-garaafiga)

Codsiyada Sax ah ee loo shubay & Farsamada

Sifooyinka farsamada ee gaarka ah ee loo yaqaan 'Crucibles' waxay taageeraan baahiyaha warshadaha ee adag:

- Joogtaynta qaab-dhismeedka oo ka hooseysa cadaadiska farsamada ee 15-20 MPa

- Xasillooni cabbireed oo joogto ah (±0.1% isbeddelka mugga ee 1500°C)

- Habayn aan wasakh lahayn oo loogu talagalay qaybaha heerka hawada sare

- Waxqabad lagu kalsoonaan karo oo ku jira nidaamyada shubka centrifugal

Heer Sare oo Wax-soo-saarka Kiimikada

Crucibles-ka RBSC waxay wax ka qabtaan caqabadaha muhiimka ah ee ku jira isku-darka kiimikada:

- Cusbo dhalaalay oo si ammaan ah loo hayo (tusaale ahaan, NaOH, KNO₃)

- Hawlgal deggan oo ku saabsan falgallada sulfidation/chlorine

- Iska caabbinta daxalka ee ka dhanka ah HF ilaa 800°C

- Ilaalinta daahirnimada ee soo saarista walxaha dhulka naadirka ah

Dhaqaalaha Hawlgalka

In kasta oo kharashyada bilowga ah ay 40-60% ka sarreeyaan kuwa dhaqameed, xalalka RBSC waxay bixiyaan:

- 70% hoos u dhac ku yimid soo noqnoqoshada beddelka

- 25–35% keydinta tamarta iyada oo loo marayo hufnaanta kulaylka oo la hagaajiyay

- 90% dib-u-warshadayn walxo ah iyada oo loo marayo dib-u-warshadaynta kulaylka

- Shuruudaha dayactirka oo ku dhow eber

Hal-abuurrada Gaarka ah ee Warshadaha

1. Soo saarista Daawaha Titanium

- Waxay u adkaysataa dhalaalka Ti-ga falcelinta leh 1700°C

- Waxay ka hortagtaa wasakhowga soo qaadista kaarboonka

2. Isku-darka Walxaha Baytariga

- Waxay awood u siineysaa farsamaynta LiCoO₂ kathode-ka midaysan

- Waxay ka hortagtaa daxalka milixda lithium

3. Kobaca Kelyaha ee Semiconductor-ka

- Waxay ilaalisaa iswaafajinta faakuumka aadka u sarreeya

- Waxay baabi'isaa wasakhaynta silikoon carbide

Naqshadeynta Mustaqbalka-Horumarka

Gawaarida casriga ah ee RBSC waxay leeyihiin astaamo horumarsan:

- Qaab-dhismeedka daloolada kala-goysyada ee loogu talagalay marin-u-helka gaaska ee la xakameeyey

- Dahaarka dusha sare ee Nanoscale wuxuu xoojiyaa iska caabbinta slag

- Dareemayaasha kuleylka ee la dhex geliyay si loola socdo habka

Laga bilaabo cilmi-baarista heerka shaybaarka ilaa wax soo saarka warshadaha, walxaha carbide-ka ee silicon-ka ku xiran ee falcelinta ku shaqeeya ayaa sii wada inay dib u qeexaan awoodaha habaynta kulaylka. Isku-darka gaarka ah ee sifooyinka kulaylka, farsamada, iyo kiimikada ayaa u dhigaya inay yihiin qalabka ugu habboon ee loogu talagalay codsiyada heerkulka sare ee jiilka soo socda, taasoo horseedaysa hufnaanta iyo horumarinta tayada qaybaha wax soo saarka ee horumarsan ee badan.

Waqtiga boostada: Maarso-20-2025