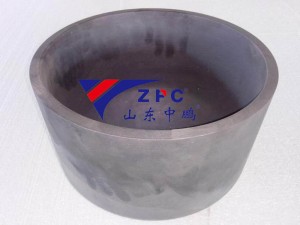

Cov tshuaj tiv thaiv sib txuas silicon carbidecov cruciblessawv cev rau kev tshawb pom tshiab hauv kev siv tshuab refractory, muab kev ua tau zoo tsis muaj qhov sib piv hauv qhov chaw kub heev. Cov thawv ceramic siab heev no tau dhau los ua qhov tseem ceeb hauv kev lag luam metallurgy, precision casting, mechanical engineering, thiab kev lag luam ua tshuaj lom neeg, xa cov haujlwm zoo dua qhov twg cov khoom siv ib txwm tsis txaus.

Cov Kev Zoo ntawm Cov Txuj Ci Tseem Ceeb

RBSC crucibles ua tau zoo dua li cov alumina thiab graphite counterparts ib txwm muaj los ntawm:

- Kev ua tau zoo heev ntawm kev ua kom sov (120–150 W/m·K ntawm 1000°C)

- Cov coefficient ntawm kev nthuav dav thermal uas tsis tshua muaj (4.5 × 10⁻⁶ / K)

- Kev tiv thaiv thermal poob siab nrog 50+ lub voj voog txias sai (1600 ° C → 25 ° C)

- Kev tiv taus acid/alkali corrosion (pH 0–14 sib xws)

- Kev ruaj khov ntawm oxidation hauv huab cua txog li 1650 ° C

Kev Paub Txog Metallurgical

Hauv kev tsim cov hlau sib xyaw thiab kev sib xyaw cov hlau uas tsis yog ferrous (txhuas, tooj liab, zinc), RBSC crucibles ua rau:

- 20–30% sai dua cov nqi yaj los ntawm kev hloov pauv cua sov zoo tshaj plaws

- 99.95% kev tswj hwm cov hlau huv si ntawm cov chaw tsis muaj tshuaj lom

- Txo cov slag tsim los ntawm kev txo qis thermal stratification

- Lub neej ua haujlwm ntev dua (3–5 × ntev dua li cov av nplaum-graphite crucibles)

Kev Ua Yeeb Yam Precision Casting & Mechanical Applications

Cov khoom siv kho tshuab tshwj xeeb ntawm cov crucibles txhawb nqa cov kev xav tau ntawm kev lag luam:

- Kev ruaj khov ntawm cov qauv hauv qab 15-20 MPa kev ntxhov siab ntawm lub cev

- Kev ruaj khov ntawm qhov ntev (± 0.1% volumetric hloov ntawm 1500 ° C)

- Kev ua cov khoom siv aerospace uas tsis muaj kuab paug

- Kev ua tau zoo hauv cov tshuab centrifugal casting

Kev Ua Tshuaj Zoo Tshaj Plaws

Cov khoom siv RBSC daws cov teeb meem tseem ceeb hauv kev tsim tshuaj lom neeg:

- Kev tswj cov ntsev uas yaj tau zoo (piv txwv li, NaOH, KNO₃)

- Kev ua haujlwm ruaj khov hauv kev sib xyaw sulfidation / chlorination

- Kev tiv thaiv corrosion tiv thaiv HF txog li 800 ° C

- Kev khaws cia purity hauv kev rho tawm cov khoom tsis tshua muaj av

Kev Lag Luam Kev Ua Haujlwm

Txawm hais tias tus nqi pib yog 40–60% siab dua li cov crucibles ib txwm muaj, RBSC cov kev daws teeb meem xa:

- Txo 70% ntawm kev hloov zaus

- Txuag hluav taws xob tau 25–35% los ntawm kev ua kom zoo dua qub ntawm kev ua kom sov

- 90% cov khoom siv rov ua dua tshiab los ntawm kev siv thermal reclamation

- Yuav luag tsis tas yuav tsum tau saib xyuas ntau

Kev Tsim Kho Tshiab Tshwj Xeeb rau Kev Lag Luam

1. Kev Tsim Khoom Titanium Alloy

- Tiv taus cov tshuaj Ti reactive ntawm 1700 ° C

- Tiv thaiv kom tsis txhob muaj pa roj carbon ntau dhau

2. Kev Sib Xyaws Khoom Siv Roj Teeb

- Pab kom muaj kev ua tiav cathode LiCoO₂ sib xws

- Tiv taus cov kua qaub ntsev lithium corrosion

3. Kev Loj Hlob ntawm Semiconductor Crystal

- Tswj kev sib raug zoo ntawm lub tshuab nqus tsev ultra-high

- Tshem tawm cov tshuaj lom neeg silicon carbide

Kev Tsim Qauv Yav Tom Ntej

Cov khoom siv RBSC niaj hnub no muaj cov yam ntxwv siab heev:

- Cov qauv porosity gradient rau kev tswj cov pa roj permeability

- Nanoscale nto coatings txhim kho slag tsis kam

- Cov ntsuas kub uas muab tso rau hauv rau kev saib xyuas cov txheej txheem

Txij li kev tshawb fawb hauv chav kuaj mus rau kev tsim khoom loj hauv kev lag luam, cov khoom siv silicon carbide uas tau sib txuas ua ke txuas ntxiv txhais dua cov peev xwm ua haujlwm thermal. Lawv qhov kev sib xyaw ua ke ntawm cov khoom thermal, mechanical, thiab chemical ua rau lawv yog cov khoom siv xaiv rau cov kev siv kub siab rau tiam tom ntej, tsav kev ua haujlwm zoo thiab kev txhim kho zoo thoob plaws ntau qhov kev lag luam tsim khoom siab heev.

Lub sijhawm tshaj tawm: Lub Peb Hlis-20-2025