I-silicon carbide kanye ne-silicon nitride azimanzi kahle ngensimbi encibilikisiwe. Ngaphandle kokuthi zingenelwa yi-magnesium, i-nickel, i-chromium alloy kanye nensimbi engagqwali, azimanzi kwezinye izinsimbi, ngakho-ke zinokumelana okuhle kakhulu nokugqwala futhi zisetshenziswa kabanzi embonini ye-aluminium electrolysis.

Kuleli phepha, ukumelana nokugqwala kwe-silicon carbide ephinde yasetshenziswa i-R-SiC kanye ne-silicon nitride bonded silicon carbide i-Si3N4-SiC ekuncibilikeni kwe-alloy ye-Al-Si ejikeleza ngokushisa kuhlolwe kusukela ezindaweni eziningi.

Ngokusho kwedatha yokuhlola yezikhathi ezingu-9 zokujikeleza kokushisa okungu-1080h ku-495 ° C ~ 620 ° C i-aluminium-silicon alloy melt, imiphumela yokuhlaziya elandelayo itholiwe.

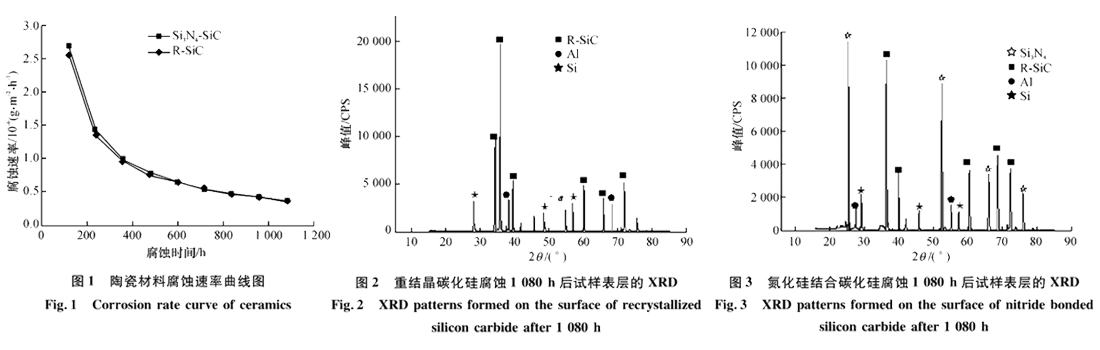

Amasampula e-R-SiC kanye ne-Si3N4-SiC anda ngesikhathi sokugqwala kanti izinga lokugqwala lehla. Izinga lokugqwala lihambisana nobudlelwano be-logarithmic bokunciphisa. (isithombe 1)

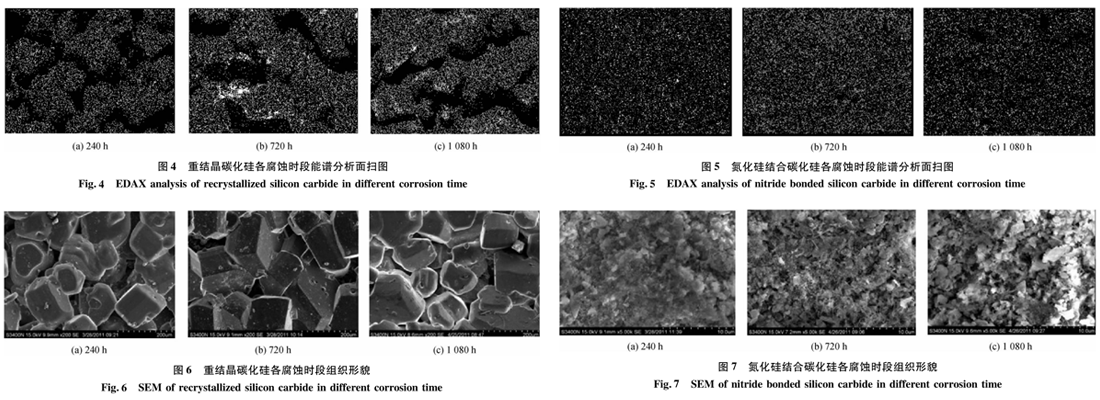

Ngokuhlaziya i-energy spectrum, amasampula e-R-SiC kanye ne-Si3N4-SiC ngokwawo awanawo ama-aluminium-silicon; kuphethini ye-XRD, inani elithile le-aluminium-silicon peak liyi-surface-residual aluminium-silicon alloy. (Isithombe 2 - Isithombe 5)

Ngokusebenzisa ukuhlaziywa kwe-SEM, njengoba isikhathi sokugqwala sanda, isakhiwo sonke samasampula e-R-SiC kanye ne-Si3N4-SiC siyaxega, kodwa akukho monakalo osobala. (Isithombe 6 - Isithombe 7)

Ukuqina kobuso σs/l>σs/g kwesixhumanisi esiphakathi koketshezi lwe-aluminium kanye ne-ceramic, i-engeli yokumanzisa θ phakathi kwezixhumanisi ingu->90°, kanti isixhumanisi esiphakathi koketshezi lwe-aluminium kanye nezinto ze-ceramic zeshidi asimanzi.

Ngakho-ke, izinto ze-R-SiC kanye ne-Si3N4-SiC zinhle kakhulu ekumelaneni nokugqwala ngokumelene nokuncibilika kwe-aluminium silicon futhi azinawo umehluko omkhulu. Kodwa-ke, izindleko zezinto ze-Si3N4-SiC ziphansi kakhulu futhi zisetshenziswe ngempumelelo iminyaka eminingi.

Isikhathi sokuthunyelwe: Disemba 17-2018