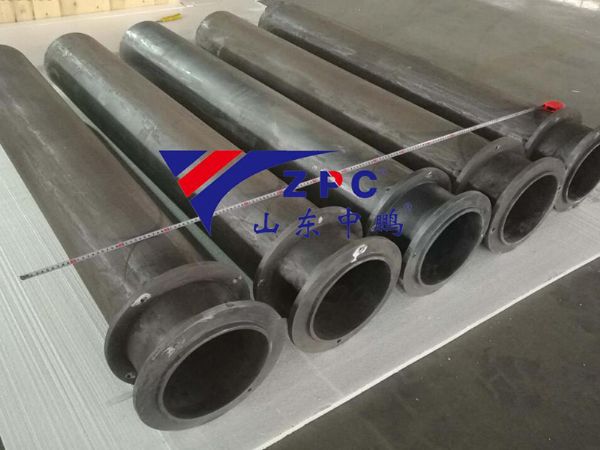

Amashubhu e-silicon carbide akhanyayo

Amashubhu e-silicon carbide akhanyayoziyizingxenye ze-ceramic ezithuthukisiwe eziqashelwa kabanzi ngokusebenza kwazo okuvelele ekusetshenzisweni kwezimboni okushisa okuphezulu nokugqwala. Izakhiwo zazo eziyingqayizivele zezinto ezibonakalayo kanye nokuzivumelanisa nezimo kwesakhiwo kuzenza zibe yinto ebalulekile ezindaweni zokusebenza ezidinga kakhulu. Ngezansi umbono ophelele wezinzuzo zazo ezibalulekile kanye nezicelo.

1. Izakhiwo Ezinhle Zezinto Ezibonakalayo

I-SiC iyinto yobumba esebenza kahle kakhulu enezici ezivelele:

(1)Ukumelana Nokushisa Okukhulu: Iyakwazi ukusebenza ngokuqhubekayo emazingeni okushisa afinyelela ku-1600°C kanye nokuchayeka isikhathi esifushane okudlula ku-1800°C, okudlula kakhulu izixazululo zendabuko ezisekelwe ensimbi.

(2)Ukushisa Okuphezulu: Njengoba kushisa okuphindwe kabili kuya kathathu kunezinsimbi, amashubhu e-silicon carbide radiant avumela ukushisa okusheshayo kanye nokusatshalaliswa kokushisa okufanayo.

(3)Ukwanda Okuphansi Kokushisa: Ukwanda kwabo okuncane kokushisa kunciphisa ukucindezeleka ngesikhathi sokushintshashintsha kwezinga lokushisa, okuqinisekisa ukuqina kwesakhiwo.

(4)Ukumelana Nokugqwala Nokuvundisa: Kumelana nama-asidi, ama-alkali, izinsimbi ezincibilikisiwe, namagesi anamandla, ngisho nangaphansi kwezimo zokushisa eziphakeme isikhathi eside.

2. Ukuguquguquka Kwesakhiwo

Amashubhu e-silicon carbide radiant angenziwa ngokwezidingo ezahlukene zezimboni:

(1)Imiklamo Engenziwa Ngokwezifiso: Itholakala ngokulungiselelwa okuqondile, okumise okwe-U, noma okumise okwe-W ukuze kuthuthukiswe ukusatshalaliswa kokushisa kanye nokusetshenziswa kwesikhala.

(2)Ukuhlanganiswa Okuqinile: Kuhambisana nama-flange ensimbi noma izinhlelo zokuvala ze-ceramic zokuxhuma okuvimbela ukuvuza kumasethingi ayinkimbinkimbi.

- Izinzuzo Zokusebenza

(1)Ukusebenza Kahle Kwamandla: Ukushisa okuphezulu kunciphisa ukusetshenziswa kwamandla ngokuvumela ukudluliselwa kokushisa okusheshayo.

(2)Impilo Ende Yesevisi: Amashubhu e-silicon carbide akhanya ngokuvamile ahlala isikhathi eside ngokuphindwe ka-3-5 kunezinye izindlela zensimbi ezindaweni ezinzima, okunciphisa isikhathi sokungasebenzi kanye nezindleko zokufaka esikhundleni.

(3)Ukumelana Nokushisa Okushisayo: Imelana nemijikelezo yokushisa okusheshayo nokupholisa ngaphandle kokuqhekeka, ilungele izinqubo ezidinga ukushintsha kwezinga lokushisa njalo.

4. Izicelo Eziyinhloko Zezimboni

Amashubhu e-silicon carbide radiant asebenza kahle kakhulu emikhakheni ebalulekile:

(1)I-Metallurgy: Isetshenziswa kuma-annealing furnaces, kuma-carburizing furnaces, kanye nasezinhlelweni ze-brazing ukuze kusetshenziswe ukushisa okufanayo.

(2)Ukucubungula Amakhemikhali: Kusebenza njengamashubhu okusabela noma izisekelo ze-catalyst kuma-reactor ashisa kakhulu kanye nama-pyrolysis furnaces.

(3)Ukukhiqizwa Kwezinto Zobumba/Ingilazi: Qinisekisa ukulawulwa okunembile kokushisa kuma-oven ashisayo kanye nezitofu ezincibilikisa ingilazi.

(4)Izinhlelo Zemvelo: Zifakwa ezindaweni zokushisa imfucuza kanye nasezindaweni zokuhlanza ukukhishwa kwegesi ukuze ziphathe amagesi agqwalisayo emazingeni okushisa aphezulu.

5. Izinzuzo Eziqhathaniswayo Ngaphezu Kwezinye Izindlela:

| Impahla | Amashubhu e-silicon carbide akhanyayo | Amapayipi Ensimbi | Amapayipi e-Quartz |

| Izinga Lokushisa Eliphezulu | 1600℃ | <1200℃ | <1200℃ (isikhathi esifushane) |

| Ukumelana Nokugqwala | Kuhle kakhulu | Okumaphakathi | Kubi ezindaweni ezine-alkaline |

| Ukumelana Nokushaqeka Okushisayo | Phezulu | Phansi | Okumaphakathi |

6. Kungani Kufanele Ukhethe Amashubhu Akhazimulayo E-Silicon Carbide?

Amashubhu e-silicon carbide radiant ayisinqumo esihle kakhulu sezimboni ezibeka phambili:

(1)Ukuqina kwezinga lokushisa okukhulu ngaphandle kokuwohloka kokusebenza.

(2)Ukuthembeka kwesikhathi eside ezindaweni ezigqwalisayo noma ezikhipha i-oxidation.

(3)Ukushisa okusebenzisa amandla kahle futhi okufanayo kwezinqubo eziqhutshwa ngokunemba.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.