Iithayile zeSilicon Carbide Ceramic

Yenzelwe ukumelana nemingeni enzima yokusebenza,iithayile ze-silicon carbideiye yaba yinto esetyenziswa kakhulu kumashishini afuna ukhuseleko lokuguguleka olungapheliyo. Isakhiwo sayo esincinci esikhethekileyo senza umsebenzi ogqwesileyo kwezi zinto zilandelayo:

- Iindawo ezinzima zokukrala eziphatha iinxalenye ezirhabaxa (>5mm)

- Uhlu olunempembelelo enkulu kunye neenkqubo zokukhupha amanzi

- Uthutho lwezinto ezidlakadlaka kwiindawo zokucubungula iikorale kunye nezityalo zeekhemikhali

Ukususela kwiindlela zokuthutha i-slag ze-steel mill ukuya kwiindawo zokutywina zoomatshini kwimveliso yezinto eziluhlaza,iithayile ze-silicon carbideIzixhobo zisebenza njengezixhobo zokuzikhusela ezenziwe ngobunjineli - zikhusela ngokuchanekileyo iindawo ezibalulekileyo zokuguguleka ngelixa zigcina uzinzo olulinganayo phantsi koxinzelelo oluqhubekayo.

Njengoko imfuno isanda kwiithayile ze-silicon carbide, ii-liners, kunye neepayipi kwiindlela zokucubungula izimbiwa, abathengi abaqondayo kufuneka babeke phambili ezi milinganiselo:

1. Ukwenziwa Kwezinto Eziqhutywa Yilifa

Ikhompawundi yethu evela eJamani ivavanywa kakhulu, ifikelela kumazinga okulahleka kwezinto ezingaphantsi kwe-0.86㎝³ – ubungqina bokuthembeka kwethayile ze-silicon carbide matrix.

2. Iprotokholi yoQinisekiso loBulukhuni

Iithayile ze-silicon carbide ziphantsi kwemephu yoxinzelelo lwe-triaxial, ebonisa ubunzima obutsha be-Mohs obuyi-14.55±4.5 kunye nomahluko we-≤2% we-MOR kwiibhetshi zemveliso.

3. Ulawulo oluchanekileyo loxinano

Ukusila okungaphantsi komgangatho kudala ubuthathaka besakhiwo. Inkqubo yethu yeethayile ze-silicon carbide igcina uxinano lwe-3.03±0.05g/㎝³ ngokusebenzisa i-pressure-assisted reaction bonding, isusa i-subsurface voids.

4. Ukugqibelela kweJiyometri

▸ Ubungqingqwa bomphezulu obungqinwe yi-laser (<0.02mm/m²)

▸ Ukuqina kwerediyasi yomphetho (0.5±0.1mm)

▸ Isiqinisekiso se-100% sokungabi nazimfanta/iimbobo

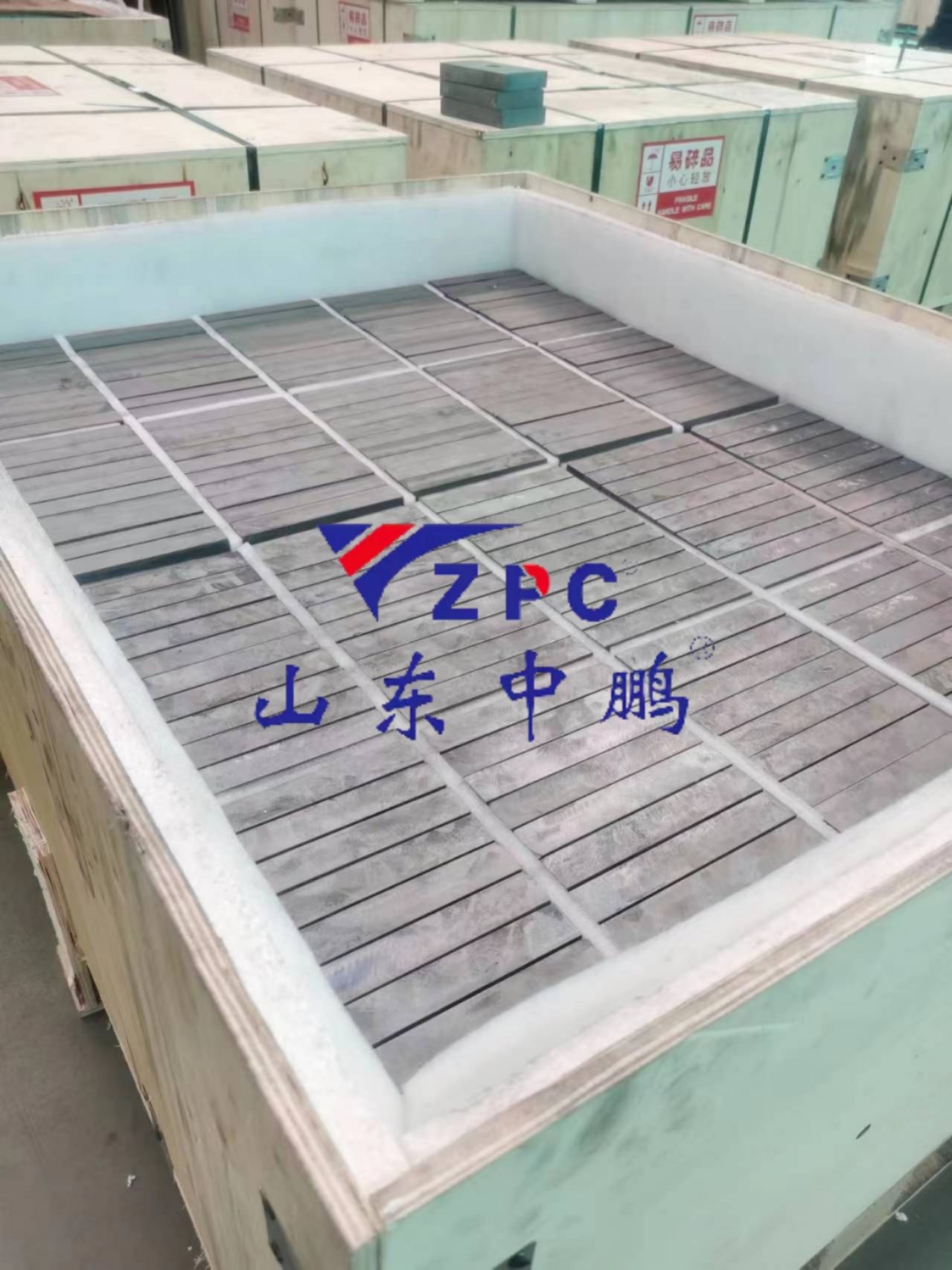

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.