Fale-falen yumbu na Silicon Carbide

An ƙera shi don jure wa ƙalubalen aiki mai tsanani,fale-falen silicon carbideya zama abin da ake amfani da shi a masana'antu da ke buƙatar kariya daga lalacewa. Tsarinsa na musamman yana ba da kyakkyawan aiki a cikin:

- Yankunan gogewa masu nauyi suna sarrafa barbashi masu kauri (−5mm)

- Tsarin rarrabawa da kuma rage yawan ruwa mai ƙarfi

- Sufurin kafofin watsa labarai masu lalata a masana'antar sarrafa murjani da sinadarai

Daga na'urorin niƙa ƙarfe zuwa fuskokin hatimin injiniya a fannin samar da kayan aiki,fale-falen silicon carbidesassan suna aiki a matsayin sulke da aka ƙera - suna kare mahimman wuraren lalacewa yayin da suke kiyaye daidaiton girma a ƙarƙashin matsin lamba mai ci gaba.

Yayin da buƙatar tayoyin silicon carbide, layuka, da bututu ke ƙaruwa a cikin sarƙoƙin sarrafa ma'adinai, masu saye masu hankali ya kamata su ba da fifiko ga waɗannan ma'auni:

1. Tsarin Gado Mai Tushe

Masana'antarmu ta asali daga Jamus tana fuskantar gwaje-gwaje da yawa na zaizayar ƙasa, inda take samun asarar kayan ƙasa da 0.86㎝³ - shaida ce ta ingancin matrix na tayal ɗin silicon carbide.

2. Yarjejeniyar Tabbatar da Tauri

Ana yin taswirar damuwa ta silicon carbide ta hanyar amfani da triaxial stress, wanda ke nuna taurin Mohs na 14.55±4.5 tare da bambancin ≤2% MOR a cikin rukunin samarwa.

3. Kula da Daidaito na Yawan Kauri

Rashin daidaiton sintering yana haifar da raunin tsarin. Tsarin tayal ɗin silicon carbide ɗinmu yana kiyaye yawan 3.03±0.05g/㎝³ ta hanyar haɗin amsawar da aka yi da matsin lamba, yana kawar da gurɓatattun abubuwa a ƙarƙashin ƙasa.

4. Kammalawar Geometric

▸ Faɗin saman da aka tabbatar da laser (<0.02mm/m²)

▸ Daidaiton radius na gefen (0.5±0.1mm)

▸ Takardar shaidar 100% ba tare da fasawa/rami ba

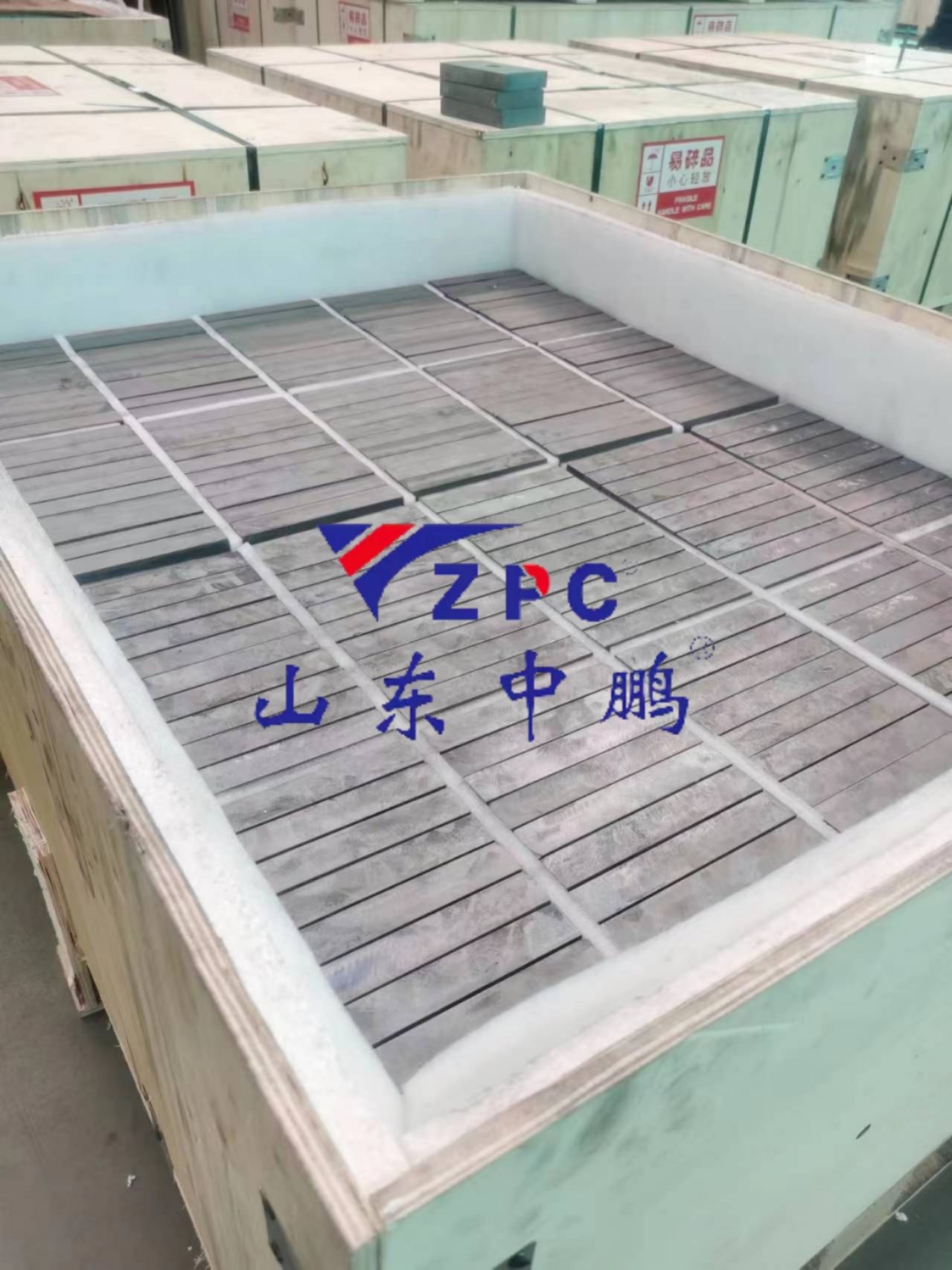

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.