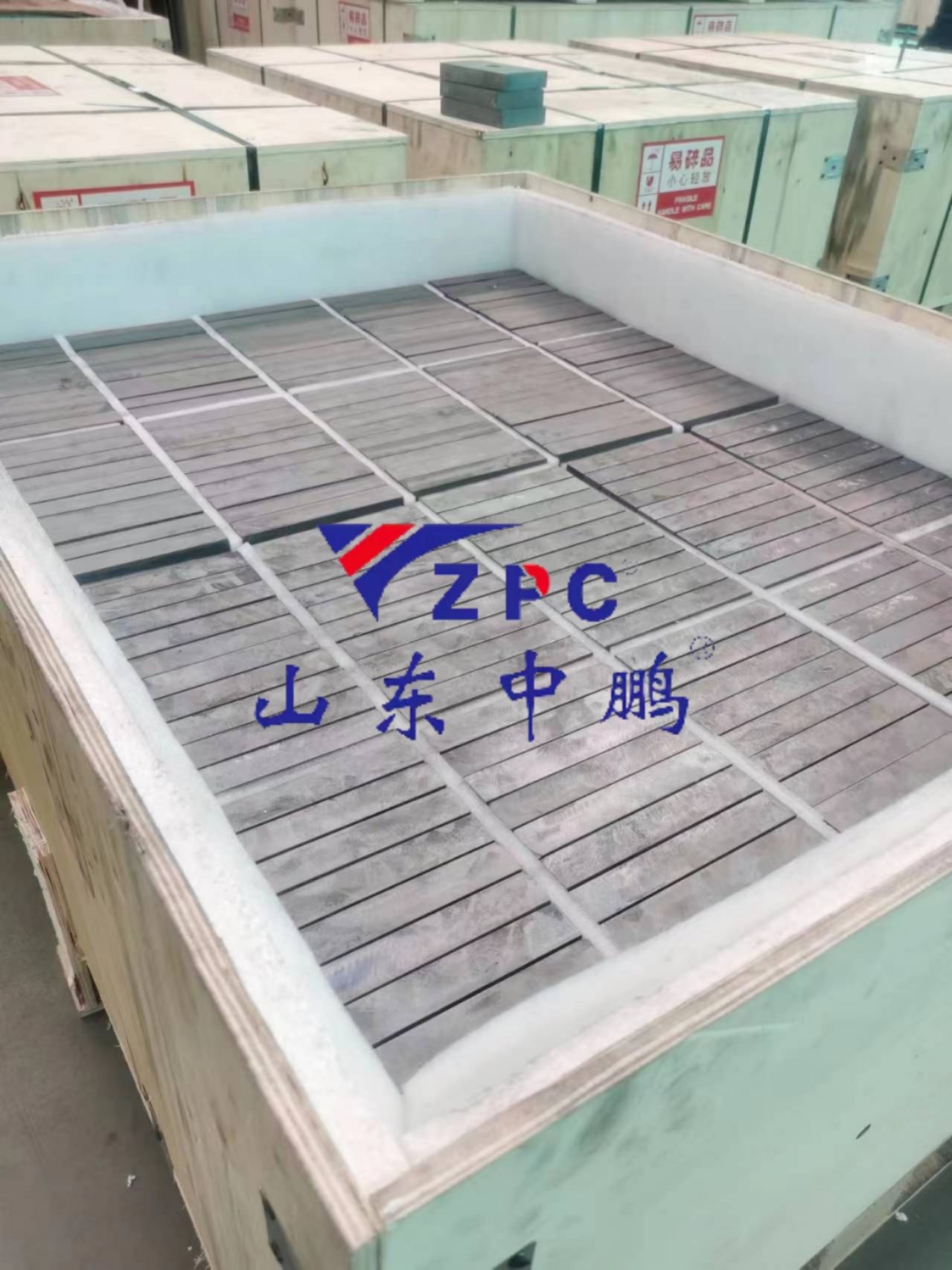

Silicon Carbide Ceramic mataira

Yakagadzirwa kuti ikwanise kutsungirira matambudziko makuru ekushanda,mataira esilicon carbiderave chinhu chinoshandiswa pakugadzira zvinhu zvemaindasitiri anoda dziviriro yakakwana yekupfeka. Chimiro chayo che microscopic chinoita basa rakanaka mu:

- Nzvimbo dzakaoma dzekukwesha dzinobata tunhu twakakora (> 5mm)

- Kupatsanura zvine simba guru uye masisitimu ekudzima mvura

- Kutakurwa kwezvinhu zvinoparadza mumiti yekugadzira makorari nemakemikari

Kubva pamidziyo yesimbi inopinza zvinhu kusvika kumeso echisimbiso chemakanika mukugadzirwa kwezvinhu zvakagadziriswa,mataira esilicon carbidezvikamu zvinoshanda senhumbi dzekudzivirira dzakagadzirwa neinjiniya - zvinonyatsodzivirira nzvimbo dzinonyanya kupfekwa uku zvichichengetedza kugadzikana kwehukuru pasi pekumanikidzwa kunogara kuripo.

Sezvo kudiwa kuri kuwedzera kwemataira esilicon carbide, ma liner, nemapaipi mucheni dzekugadzirisa zvicherwa, vatengi vane njere vanofanira kuisa pamberi zviratidzo izvi:

1. Kuumbwa Kwakatungamirirwa Nenhaka

Musanganiswa wedu wepakutanga wekuGermany unoedzwa kakawanda, zvichiita kuti kurasikirwa kwezvinhu kuve pasi pe0.86㎝³ - humbowo hwekuti silicon carbide tiles integrity.

2. Protocol Yekusimbisa Kuoma

Mataira esilicon carbide anoongororwa ne triaxial stress mapping, zvichiratidza kuomarara kweMohs itsva 14.55±4.5 ne ≤2% MOR variance pakati pema production batches.

3. Kudzora Kunyatsoona Kuwanda Kwevanhu

Kupisa kusina kunaka kunoita kuti pave nekusasimba kwechimiro. Maitiro edu ekutaira mataira esilicon carbide anochengetedza huwandu hwe3.03±0.05g/㎝³ kuburikidza nekubatanidza kwepressure-assisted reaction, zvichibvisa mavoid ari pasi pevhu.

4. Kukwana kweJomethri

▸ Kureba kwenzvimbo kwakasimbiswa nelaser (<0.02mm/m²)

▸ Kuenderana kweredhiyo yemucheto (0.5±0.1mm)

▸ Chitupa che 100% chisina kutsemuka/maburi

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.