Umenzi (umzi-mveliso) wezitena zeSilicon Cabide, iipleyiti, iithayile

I-Silicon Carbide inyamezela uluhlu olubanzi lwee-asidi kunye nee-alkali. Kwaye isebenza kakuhle kakhulu, inamandla aphezulu, inamandla aphezulu okuguguleka, inamandla aphezulu obushushu, inamandla okugqwala. Iindidi ezahlukeneyo zeemilo zeendawo ezikhethekileyo zifanelekile kwimigodi, i-petrochemical, imveliso ye-metallurgical, i-aerospace kunye nemizi-mveliso yenyukliya, njengendawo ethile. Singenza naziphi na iisayizi ezibonelelwa ngokwesicelo somthengi.

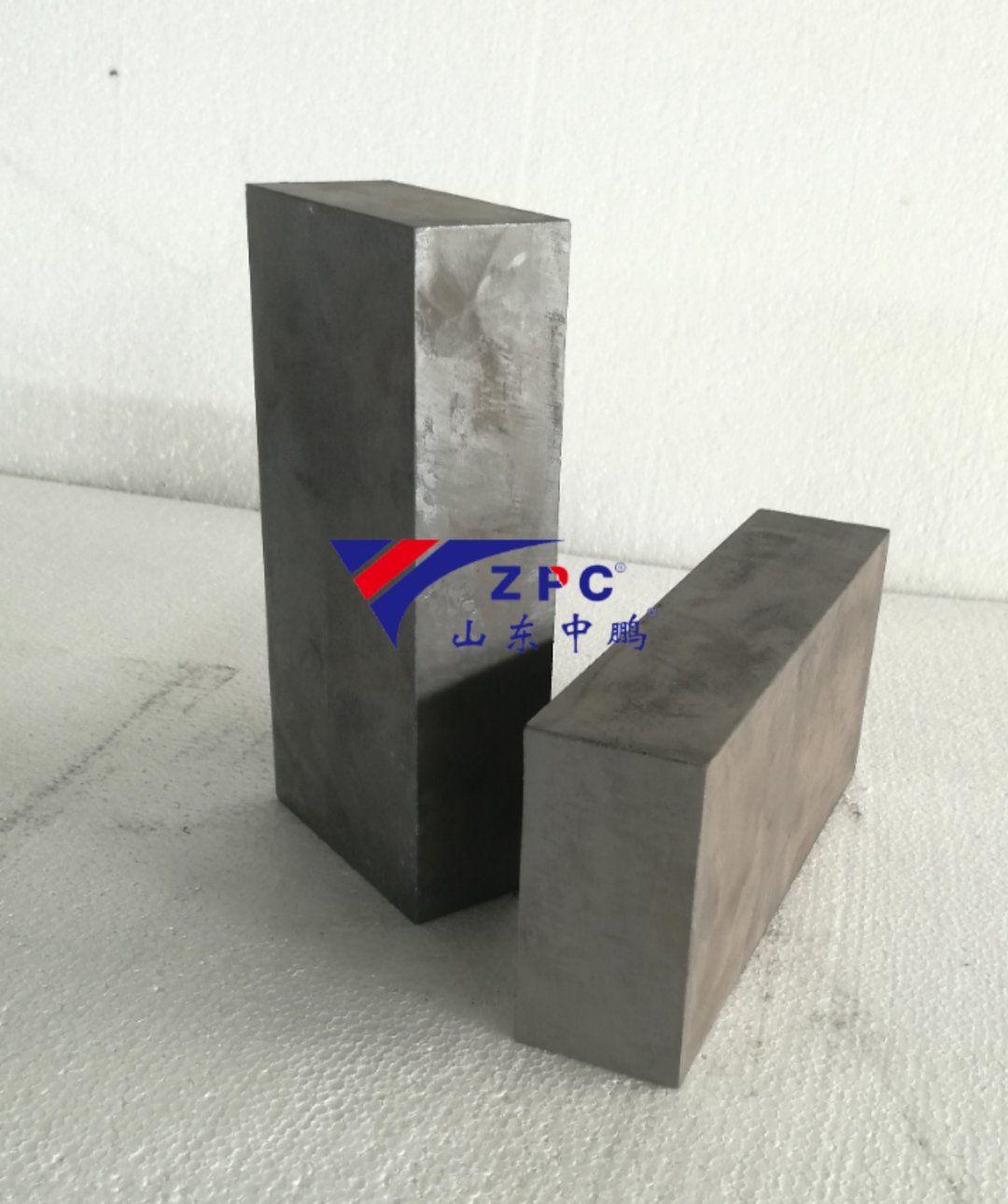

Ukumelana nokuguguleka, amandla obushushu aphezulu kunye nokumelana nokugqwala kwenza iReaction Bonded SiC ibe yinto efanelekileyo kwiindawo zokuguguleka, ezifana neepayipi, izitena, iithayile, iibhloko, njl.njl.

| Abalinganiswa bezinto ezibonakalayo | Iyunithi | Iipropati |

| Umxholo we-SIC | % | 95-88 |

| Si yasimahla | % | 5~12 |

| Unizi lolwapho kuyiwa khona | g/cm3 | >3.02 |

| Ukugquma | % | <0.1 |

| Ukuqina | kg/mm2 | 2400 |

| Amandla okugoba alinganayo kwi-20 degrees Celsius | I-Mpa | 260 |

| Amandla okugoba aqina kwi-1200 degrees Celsius | I-Mpa | 280 |

| Imodulus yokuthamba kwi-20 degrees Celsius | I-Gpa | 330 |

| Ukuqina kokwaphuka | I-Mpa*m1/2 | 3.3 |

| I-coefficient ye-thermal conductivity kwi-1200 degrees Celsius | W/mk | 45 |

| I-coefficient yokwandisa ubushushu kwi-1200 degrees Celsius | 10-6mm/mmK | 4.5 |

| I-coefficient yemitha yobushushu | <0.9 | |

| Ubushushu obuphezulu bokusebenza | ºC | <1380 |

Iimpawu zeSilicon Carbide SiC (SiSiC/RBSiC):

Ukumelana nokukrala/nokugqwala

Iimpawu ezintle kakhulu zoxinzelelo lobushushu

Ukumelana kakuhle kwe-oxidation

Ulawulo olufanelekileyo lobukhulu beemilo ezintsonkothileyo

Ukuqhuba okuphezulu kobushushu

Ukusebenza okuphuculweyo

Ubomi obude phakathi kokutshintshwa/ukwakhiwa kwakhona

Ukuxhathisa ukugqwala

Ukumelana okuphezulu kokunxiba

Amandla kubushushu obuphezulu ukuya kuthi ga kwi-1380°C

Iipleyiti ze-silicon carbide ezisetyenziswayo:

Ipleyiti kunye neethayile ze-SiC silicon carbide luhlobo lwepleyiti ekhethekileyo ye-ceramic esetyenziswa kakhulu kwimveliso emininzi yemizi-mveliso:

Ishishini leMigodi, Ishishini loomatshini, Ishishini leeKhemikhali, Ishishini leglasi leCrystallite, Ishishini lezixhobo zeMagnetic, iMetallurgy, Ishishini leMetallurgy, Ishishini lePhepha, Ishishini lePetroleum, i-oven, njl.

Iimveliso ze-silicon carbide ezenziwe ngokwezifiso, imilo ekhoyo: iipleyiti, izitena, iithayile, ipleyiti ye-radian, izikrufu, ipleyiti ecacileyo, umbhobho othe tye, iipayipi ze-tee, iringi, ingqiniba, i-cone cyclone njalo njalo.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.