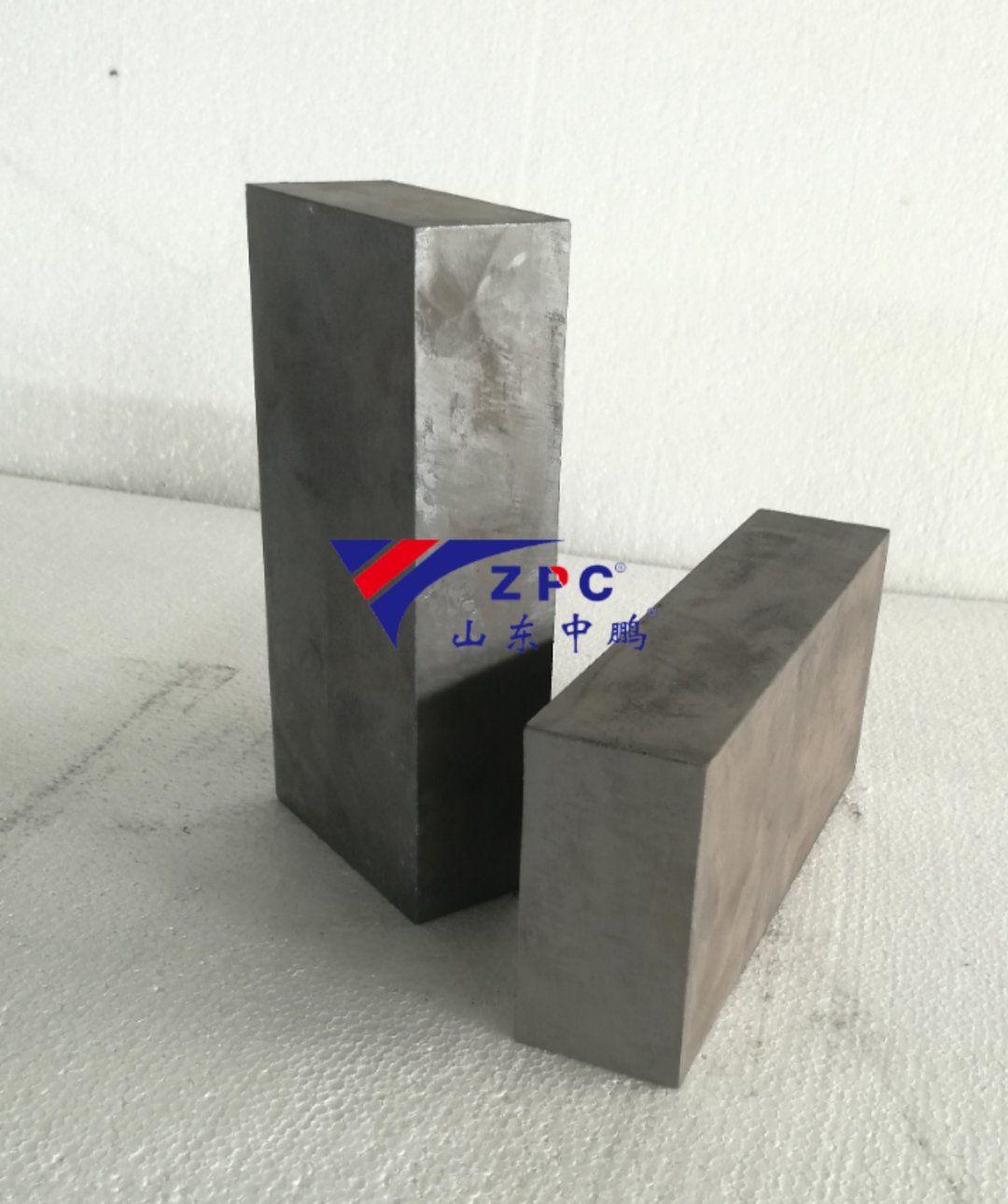

సిలికాన్ క్యాబైడ్ ఇటుకలు, ప్లేట్లు, టైల్స్ తయారీదారు (ఫ్యాక్టరీ)

సిలికాన్ కార్బైడ్ విస్తృత శ్రేణి ఆమ్లాలు మరియు క్షారాలను తట్టుకుంటుంది. మరియు అధిక బలం, అధిక కాఠిన్యం, అధిక దుస్తులు నిరోధకత, అధిక ఉష్ణోగ్రత నిరోధకత, తుప్పు నిరోధకత వంటి అద్భుతమైన పనితీరుతో. ప్రత్యేక భాగాల యొక్క వివిధ రకాల ఆకారాలు మైనింగ్, పెట్రోకెమికల్, మెటలర్జికల్ తయారీ, ఏరోస్పేస్ మరియు అణు పరిశ్రమలకు, నిర్దిష్ట వాతావరణం వంటి వాటికి అనుకూలంగా ఉంటాయి. కస్టమర్ అభ్యర్థన ప్రకారం అందించిన ఏవైనా పరిమాణాలను మేము తయారు చేయవచ్చు.

దుస్తులు నిరోధకత, అధిక ఉష్ణోగ్రత బలం మరియు తుప్పు నిరోధకత రియాక్షన్ బాండెడ్ SiC ని పైప్ లైనర్లు, ఇటుకలు, టైల్స్, బ్లాక్స్ మొదలైన దుస్తులు భాగాలకు అనువైన పదార్థంగా చేస్తాయి.

| భౌతిక పాత్రలు | యూనిట్ | లక్షణాలు |

| SIC కంటెంట్ | % | 95-88 |

| ఉచిత Si | % | 5~12 |

| బల్క్ సాంద్రత | గ్రా/సెం.మీ3 | > 3.02 |

| సచ్ఛిద్రత | % | <0.1 <0.1 |

| కాఠిన్యం | కిలో/మిమీ2 | 2400 తెలుగు |

| 20 డిగ్రీల సెల్సియస్ వద్ద వంపు బలం యొక్క గుణకం | ఎంపిఎ | 260 తెలుగు in లో |

| 1200 డిగ్రీల సెల్సియస్ వద్ద వంపు బలం యొక్క గుణకం | ఎంపిఎ | 280 తెలుగు |

| 20 డిగ్రీల సెల్సియస్ వద్ద స్థితిస్థాపకత యొక్క మాడ్యులస్ | జీపీఏ | 330 తెలుగు in లో |

| పగులు దృఢత్వం | ఎంపీఏ*మీ1/2 | 3.3 |

| 1200 డిగ్రీల సెల్సియస్ వద్ద ఉష్ణ వాహకత గుణకం | పశ్చిమ/పశ్చిమ | 45 |

| 1200 డిగ్రీల సెల్సియస్ వద్ద ఉష్ణ విస్తరణ గుణకం | 10-6మి.మీ/మి.మీ.కె. | 4.5 अगिराला |

| ఉష్ణ వికిరణ గుణకం | <0.9 <0.9 | |

| గరిష్ట పని ఉష్ణోగ్రత | ºC | <1380 · <1380 · |

సిలికాన్ కార్బైడ్ SiC (SiSiC/RBSiC) లక్షణాలు:

రాపిడి / తుప్పు నిరోధకత

అద్భుతమైన థర్మల్ షాక్ లక్షణాలు

అద్భుతమైన ఆక్సీకరణ నిరోధకత

సంక్లిష్ట ఆకారాల యొక్క మంచి డైమెన్షనల్ నియంత్రణ

అధిక ఉష్ణ వాహకత

మెరుగైన పనితీరు

భర్తీ / పునర్నిర్మాణాల మధ్య ఎక్కువ జీవితకాలం

తుప్పు నిరోధకత

ధరించడానికి ఉన్నతమైన నిరోధకత

1380°C వరకు అధిక ఉష్ణోగ్రత వద్ద బలం

సిలికాన్ కార్బైడ్ ప్లేట్ల అప్లికేషన్లు:

SiC సిలికాన్ కార్బైడ్ ప్లేట్ మరియు టైల్స్ అనేది ఒక రకమైన ప్రత్యేక సిరామిక్ ప్లేట్, వీటిని అనేక పారిశ్రామిక ఉత్పత్తిలో విస్తృతంగా ఉపయోగిస్తారు:

మైనింగ్ పరిశ్రమ, యంత్ర పరిశ్రమ, రసాయన పరిశ్రమ, స్ఫటికాకార గాజు పరిశ్రమ, అయస్కాంత పదార్థాల పరిశ్రమ, లోహశాస్త్రం, లోహశాస్త్ర పరిశ్రమ, కాగితపు పరిశ్రమ, పెట్రోలియం పరిశ్రమ, బట్టీ మొదలైనవి.

అనుకూలీకరించిన సిలికాన్ కార్బైడ్ ఉత్పత్తులు, అందుబాటులో ఉన్న ఆకారం: ప్లేట్లు, ఇటుకలు, టైల్స్, రేడియన్ ప్లేట్, స్క్రూ, ప్లెయిన్ ప్లేట్, స్ట్రెయిట్ పైపు, టీ పైపులు, రింగ్, ఎల్బో, కోన్ సైక్లోన్ మరియు మొదలైనవి.

షాన్డాంగ్ జోంగ్పెంగ్ స్పెషల్ సెరామిక్స్ కో., లిమిటెడ్ చైనాలోని అతిపెద్ద సిలికాన్ కార్బైడ్ సిరామిక్ కొత్త మెటీరియల్ సొల్యూషన్లలో ఒకటి. SiC టెక్నికల్ సిరామిక్: మోహ్ యొక్క కాఠిన్యం 9 (న్యూ మోహ్ యొక్క కాఠిన్యం 13), కోత మరియు తుప్పుకు అద్భుతమైన నిరోధకత, అద్భుతమైన రాపిడి - నిరోధకత మరియు యాంటీ-ఆక్సీకరణ. SiC ఉత్పత్తి యొక్క సేవా జీవితం 92% అల్యూమినా పదార్థం కంటే 4 నుండి 5 రెట్లు ఎక్కువ. RBSiC యొక్క MOR SNBSC కంటే 5 నుండి 7 రెట్లు ఎక్కువ, దీనిని మరింత సంక్లిష్టమైన ఆకృతుల కోసం ఉపయోగించవచ్చు. కోట్ ప్రక్రియ వేగంగా ఉంటుంది, డెలివరీ వాగ్దానం చేసినట్లుగా ఉంటుంది మరియు నాణ్యత ఎవరికీ రెండవది కాదు. మేము ఎల్లప్పుడూ మా లక్ష్యాలను సవాలు చేయడంలో పట్టుదలతో ఉన్నాము మరియు సమాజానికి మా హృదయాలను తిరిగి ఇస్తాము.