Ukusuka kwimibhobho yezothutho ukuya kwizithuthi zamandla amatsha, ukusuka kwiikhilthi zobushushu obuphezulu ukuya kwiisathelayithi ze-aerospace, imathiriyeli eyaziwa ngokuba "yidayimani yoshishino" ngokuzolileyo ibhala kwakhona imida yokwenziwa kwale mihla.Iiceramics ze-silicon carbide, imathiriyeli enzima kakhulu enobunzima besibini kuphela kwidayimane yendalo, ibangela uguquko oluthe cwaka kwiinkalo ezahlukeneyo ezifana neshishini lale mihla, i-semiconductors, i-aerospace, kunye namandla amatsha ngenxa yokumelana nobushushu obuphezulu, ukuxhathisa olomeleleyo kwimitha, kunye ne-thermal conductivity egqwesileyo.

Xa 'amathambo aqinileyo' edibana nemveliso echanekileyo

Ukuba iiseramics zemveli ziluhlaza okwesibhakabhaka kunye ne-porcelain emhlophe kubugcisa kunye nobugcisa, ke iiseramics ze-silicon carbide zifana neewotshi zaseSwitzerland kwizixhobo ezichanekileyo. Ubunzima bayo bumaxesha angama-3-5 ee-ceramics eziqhelekileyo, kwaye obu bunzima obusondeleyo kwidayimane yendalo yenza inkqubo yokugaya ifana nokukrola kwiiplate zetsimbi - izixhobo eziqhelekileyo zokusika zigugile ngesantya esimangalisayo ngexesha lokusika. Eyona nto ikhohlisayo ngakumbi kukuba indalo "enzima" yesilicon carbide iyenza ukuba ithande ukuqhekeka nokuba yimpazamo encinci ngexesha lokusetyenzwa, ngakumbi iindawo ezinodonga olucekethekileyo ezifuna isilumkiso esifanayo njengemisebenzi yobugcisa yekristale.

Kodwa imfuno yoshishino lwangoku iqhuba impumelelo yetekhnoloji. Iinjineli ziye zafumanisa ukuba isitshixo ekusombululeni le ngxaki sikukudityaniswa kokuqina kunye nokuguquguquka: ukugcina iipropati zangaphakathi zezinto ngelixa usebenzisa ulawulo oluchanekileyo ngexesha lokucubungula. Kanye njengabapheki abaphezulu bebamba ubushushu, iindlela zangoku zokulungisa ngokuthe ngcembe zithomalalisa le nto inenkani ngolawulo oluchanekileyo lobushushu, uxinzelelo, kunye nokungcangcazela rhoqo.

Izitshixo ezintathu zokuvula iidayimani zamashishini

1. Ukubumba okutshisayo

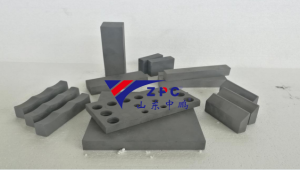

Le yenye yeendlela eziqhelekileyo zokusetyenzwa kwe-silicon carbide ceramics. Le ndlela ibeka i-silicon carbide powder okanye umgubo oxutywe kwimold ecinezelayo kwaye iyenze ibe yimo phantsi kobushushu obuphezulu kunye noxinzelelo. Inomgangatho ophezulu wokuvelisa kunye nokwenza ngokuchanekileyo, kwaye ifanelekile ukuvelisa iimveliso ze-silicon carbide zeceramic ezinkulu ezifana nezixhobo zokusika, iipleyiti ze-aluminiyam ezishushu, njl njl.

2. Ukubumba i-Grouting

Le yindlela enexabiso eliphantsi kwaye ekhawulezayo yokwenza iimveliso ze-silicon carbide ceramic. Le ndlela ixuba i-silicon carbide powder kunye nezinye izongezo, zongeze emanzini ukwenza i-slurry, kwaye igalele kwi-mold mold. Emva koko, icutshungulwa kwaye yenziwe ngokumisa kunye ne-high-temperature sintering, kunye nomjikelezo omfutshane wokucubungula kunye neendleko eziphantsi. Kufanelekile ukulungiselela ubuninzi obuphezulu, iindawo ezinobunzima obuphezulu kunye nezinto ezithwala imithwalo.

3. I-Metallurgy yomgubo

I-metallurgy ye-powder yindlela yokuxuba kunye nokubumba i-silicon carbide powder kumlinganiselo othile, kwaye emva koko uyifake kwiqondo lokushisa eliphezulu kunye noxinzelelo oluphezulu. Le ndlela inenkqubo yokuvelisa elula, iimilo zeemveliso ezahlukeneyo, kunye nokuchaneka okuphezulu kokulungiswa, okwenza kube yinto efanelekileyo yokuvelisa iimveliso ze-ceramic ezichanekileyo, ezichanekileyo, kunye nokugqoka.

Ukusuka kwiisampuli zebhubhoratri ukuya kwimveliso yobuninzi kumgca wokuvelisa, ukuphumelela ekuqhutyweni kwe-silicon carbide ceramics iqinisekisa inyaniso: akukho nto ingenakucutshungulwa, iteknoloji kuphela engekaphumi. Ngokukhula kobuchwepheshe obutsha obufana nokusetyenzwa kwelaser kunye ne-microwave sintering, le nto yayikhe yoyikeka kakhulu iyahlaziyeka kwiifektri ezikrelekrele, ifaka umbane oqinileyo “kwimveliso yobukrelekrele yaseTshayina”.

Kulwandlekazi olukhulu lokuphononongwa kwendawo kunye namaza aluhlaza ombane acocekileyo, iiseramics zesilicon carbide zibhala intsomi yemizi mveliso yeli xesha kunye nomtsalane wabo wezinto ezizodwa. Lo mboniso phakathi kobulukhuni kunye nobukrelekrele unokuba ngumfanekiso ongunaphakade woluntu olusaphula imida yetekhnoloji.

Ixesha lokuposa: Apr-09-2025