Daga bututun sufuri zuwa sababbin motocin makamashi, daga kilns masu zafi zuwa tauraron dan adam, wani abu da aka sani da "lu'u lu'u-lu'u na masana'antu" yana sake rubuta iyakokin masana'antu na zamani a hankali.Silicon carbide yumbura, wani abu mai wuyar gaske tare da taurin na biyu kawai zuwa lu'u-lu'u na dabi'a, yana haifar da juyin juya halin shiru a fannoni daban-daban kamar masana'antu na zamani, semiconductor, sararin samaniya, da sabon makamashi saboda tsananin zafinsa, juriya mai ƙarfi, da kyakkyawan yanayin zafi.

Lokacin da 'kasusuwa masu wuya' suka haɗu da ƙirar ƙira

Idan yumbu na al'ada shuɗi da fari ne a cikin zane-zane da fasaha, to yumburan siliki carbide sun fi kama agogon Swiss a cikin ainihin kayan kida. Taurinsa ya ninka sau 3-5 na yumbu na yau da kullun, kuma wannan taurin kusa da lu'u-lu'u na halitta yana sa aikin injin ya zama sassaƙa akan faranti na ƙarfe - kayan aikin yankan na yau da kullun suna lalacewa cikin sauri mai ban mamaki yayin yanke. Abin da ya fi wayo shi ne cewa yanayin “tauri” na silicon carbide yana sa ya zama mai saurin fashewa tare da ɗan ƙaramin kuskure yayin sarrafawa, musamman ga wasu sassan bangon bakin ciki waɗanda ke buƙatar taka tsantsan kamar kayan fasahar crystal.

Amma buƙatar masana'antu na zamani shine haifar da ci gaban fasaha. Injiniyoyi sun gano cewa mabuɗin magance wannan matsala yana cikin haɗuwa da tsauri da sassauci: kiyaye abubuwan da ke cikin kayan aiki yayin aiwatar da madaidaicin iko yayin sarrafawa. Kamar dai yadda manyan masu dafa abinci ke ƙware da zafi, dabarun sarrafa kayan zamani a hankali suna lalata wannan abu mai taurin kai ta hanyar daidaita yanayin zafi, matsa lamba, da mitar girgiza.

Maɓallai uku don buɗe lu'ulu'u na masana'antu

1. Zafafan gyare-gyare

Wannan shine ɗayan hanyoyin gama gari don sarrafa yumbun silikon carbide. Wannan hanya tana sanya siliki carbide foda ko gauraye foda a cikin wani zafi matsa lamba da kuma sarrafa shi zuwa siffar karkashin high zafin jiki da kuma matsa lamba. Yana da babban samar da inganci da samar da daidaito, kuma ya dace da samar da manyan sikelin silicon carbide yumbu kayayyakin kamar kayan aikin yankan, faranti mai zafi na aluminum, da sauransu.

2. Gouting gyare-gyare

Wannan hanya ce mai sauƙi da sauri don ƙirƙirar samfuran yumbu na silicon carbide. Wannan hanyar tana haɗa foda na silicon carbide da sauran abubuwan da ake ƙarawa, ta ƙara su a cikin ruwa don yin slurry, sannan a saka shi cikin ƙirar ƙira. Sa'an nan kuma, ana sarrafa shi kuma a samar da shi ta hanyar bushewa da zafin jiki mai zafi, tare da gajeren tsarin sarrafawa da ƙananan farashi. Ya dace da shirya ƙarfin ƙarfi, sassa masu yawa da kayan aiki masu ɗaukar nauyi.

3. Foda karfe

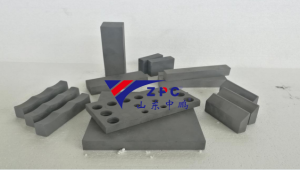

Foda karfe hanya ce ta hadawa da siffata siliki carbide foda a wani yanki na musamman, sannan kuma sanya shi a cikin matsanancin zafi da matsa lamba. Wannan hanyar tana da tsari mai sauƙi na samarwa, nau'ikan samfura daban-daban, da daidaiton aiki mai girma, yana sa ya dace da samar da madaidaicin inganci, ƙarfin ƙarfi, da samfuran yumbu masu jurewa.

Daga samfurori na dakin gwaje-gwaje don samar da taro a kan layin samarwa, nasarar da aka samu a cikin sarrafa kayan yumbura na silicon carbide ya tabbatar da gaskiya: babu wani abu da ba za a iya sarrafa shi ba, kawai fasahar da ba a riga ta karya ba. Tare da balaga da sabbin fasahohi irin su sarrafa Laser da injin microwave, wannan daɗaɗɗen abu mai ƙarfi yana sake farfadowa a cikin masana'antu masu kaifin basira, yana allurar ƙarfin ƙarfin gaske cikin “Masana ƙwararrun Sinanci”.

A cikin babban teku na binciken sararin samaniya da kuma koren kalaman makamashi mai tsafta, yumbu na silicon carbide suna rubuta almara na masana'antu na wannan zamanin tare da fara'a na musamman. Wannan nunin tsakanin tauri da hankali na iya zama madawwamin ma'auni na ɗan adam da ke keta iyakokin fasaha.

Lokacin aikawa: Afrilu-09-2025