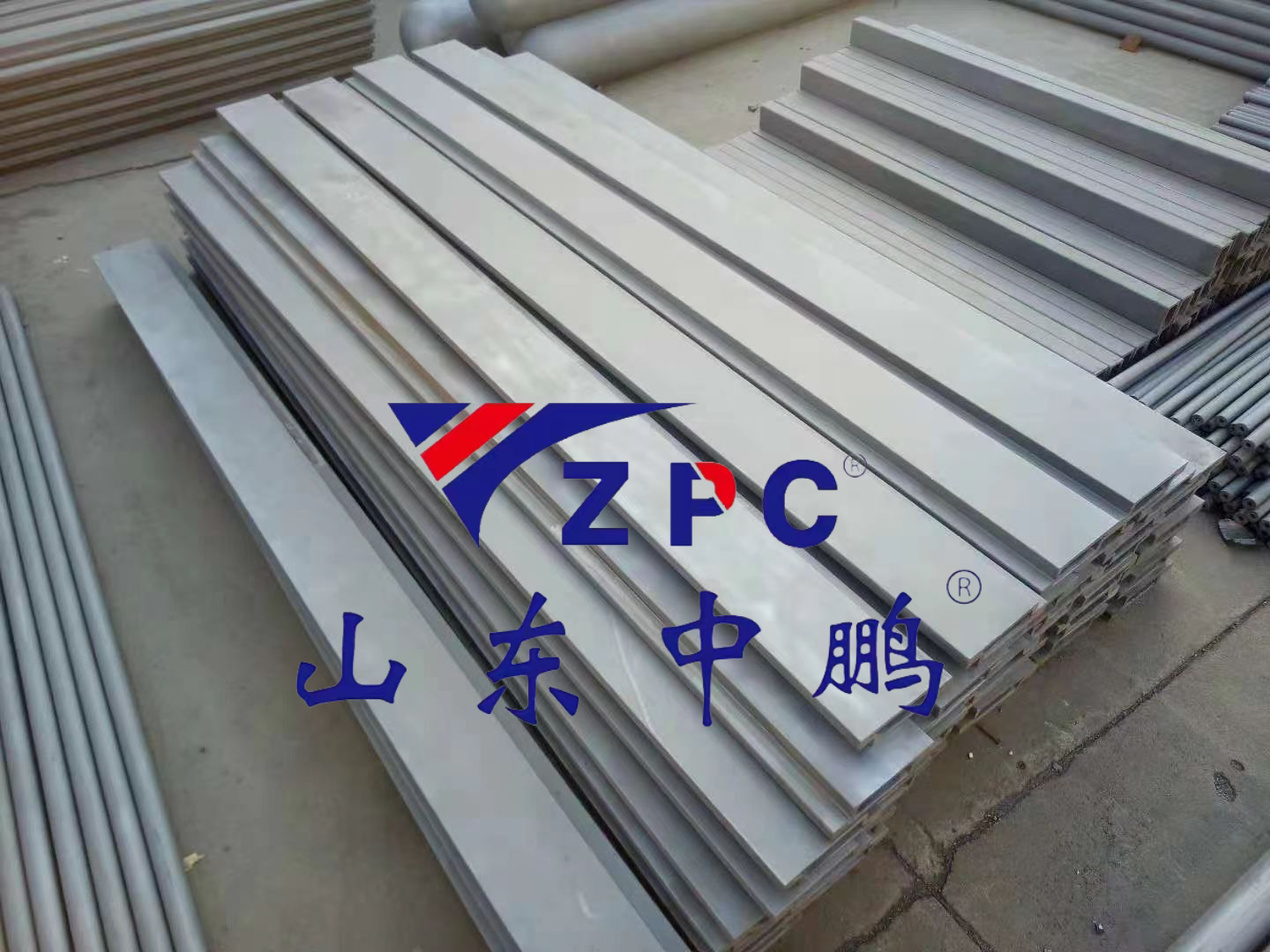

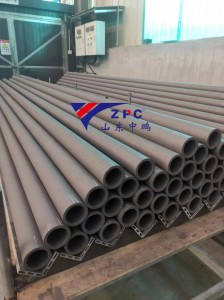

Lithako tsa silicon carbide

Lirolara tsa ceramic tsa Reaction-sintered silicon carbide (R-SiC).li hlahile e le likarolo tsa bohlokoa lits'ebetsong tsa sejoale-joale tsa ho sebetsa ka mocheso, haholo-holo tse ipabolang ka har'a tlhahiso ea betri ea lithium, tlhahiso e tsoetseng pele ea li-ceramics, le sintering e nepahetseng ea matla a khoheli. Lirolara tsena tse ikhethileng li hlalosa bocha maemo a ts'ebetso ka har'a libopi tsa liindasteri tse nang le mocheso o phahameng oa mocheso ka ho rarolla mathata a bohlokoa a botsitso ba mocheso le ho tšoarella ha mochini.

Ts'ebetso e sa Lekaneng ea Thermal

E etselitsoe ho sebetsa ka mokhoa o tsoelang pele ho 1450-1600 ° C - e phahameng haholo ho feta lirolara tse tloaelehileng tsa alumina - lirolara tsa R-SiC li boloka ho nepahala ha maemo le tlas'a libaesekele tse futhumetseng haholo. Microstructure ea bona e ikhethang e thusa:

• Ho fetisoa ha mocheso ka potlako (±5°C ho pholletsa le bolelele ba rolara)

• Ho mamella linako tse 100+ tsa mocheso oa mocheso (1400°C ↔ mocheso oa kamore)

• Lehlakore le sa tsitsang ha le fihla mochesong o tsitsitseng

Bohlokoa Likopo Tse Hlalositsoeng Bocha

1. Tlhahiso ea Battery ea Lithium

- Khokahano e nepahetseng bakeng sa sintering ea lisebelisoa tsa elektrode

- Ho sebetsana ntle le tšilafalo ea li-cathode tsa NMC/LFP

- Ts'ebetso e tsitsitseng ea ho fokotsa maemo a leholimo

2. Advanced Ceramics Processing

- Ts'ehetso ea mahala ea Warp bakeng sa lithaele tsa sebopeho se seholo (ho fihla ho 1.5 × 3m)

- Taolo e sa fetoheng ea lebelo mehala ea sanitaryware glazing

- Qetello e sa tšoaeeng holimo (Ra <0.8μm)

3. Tlhahiso ea Magnetic Material

- Potoloho e sa sisinyeheng bakeng sa ho thothomela ha ferrite

- Ho se sebetse ha lik'hemik'hale libakeng tse nang le haedrojene e ngata

Melemo ea Ts'ebetso

Bokhoni ba Mojaro: E tšehetsa 3-5 × boima bo boholo ka bolelele ba yuniti khahlano le lirolara tsa tšepe tse kopantsoeng

Deformation Resistance: E boloka <0.05mm / m e otlolohileng ka mor'a lihora tsa ts'ebetso tsa 10,000

Matla a Matla: 18-22% e fokolitse tšebeliso ea matla a sebōpi ka ho fana ka mocheso o ntlafalitsoeng

Khokahano ea Cross-Industry: E khona ho ikamahanya le libotlolo tsa shuttle, libono tsa lirolara tse ngata, le libono tse nyalisitsoeng.

Tšireletseho ea Moruo

Leha e hloka matsete a pele a 30-40% ho feta lirolara tse tloaelehileng, tharollo ea R-SiC e bonts'a:

- 70% ea nako e telele ea litšebeletso (lilemo tse 5-7 khahlanong le lilemo tse 2-3)

- 90% e ka sebelisoa hape ka mekhoa ea ho khutlisa mocheso

- 60% ea litšenyehelo tse tlase tsa tlhokomelo e tsoang libakeng tse sa tsoeng ka mahlaba

Moralo o Itokiselitseng Bokamoso

Lirolara tsa sejoale-joale tsa R-SiC joale li kenyelletsa:

- Li-grooves tse ngotsoeng ka Laser bakeng sa mela ea tlhahiso e ikemetseng

- Porosity e ka khonehang bakeng sa ho kenella ha sepakapaka se ikhethileng

- Li-sensor tse kopaneng tsa mocheso bakeng sa ts'ebetso e bohlale ea kiln

Lintlafatso tsena tsa theknoloji li beha lirolara tsa silicon carbide e le lisebelisoa tsa bohlokoahali lits'ebetsong tse futhumatsang tsa indasteri tse tlang, tse nolofalletsang bahlahisi ho fihlela taolo e matla ea mocheso, ho tsitsisa lihlahisoa tse phahameng, le phallo e tsitsitseng ea tlhahiso ho pholletsa le makala a mangata a theknoloji e phahameng.

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse ncha tsa silicon carbide ceramic China. SiC tekheniki ea ceramic: Ho thatafala ha Moh ke 9 (Bothata ba Moh e Ncha ke 13), e nang le khanyetso e babatsehang ea khoholeho ea mobu le ho bola, ho senya ho hoholo - ho hanyetsa le ho thibela oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ba makhetlo a 4 ho isa ho a 5 ho feta 92% ea lisebelisoa tsa alumina. MOR ea RBSiC ke 5 ho makhetlo a 7 ea SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea quotation e potlakile, thomello e joalo ka ha e ts'episitsoe 'me boleng ha bo na letho. Re lula re phehella ho phephetsa lipakane tsa rona le ho khutlisetsa lipelo tsa rona sechabeng.