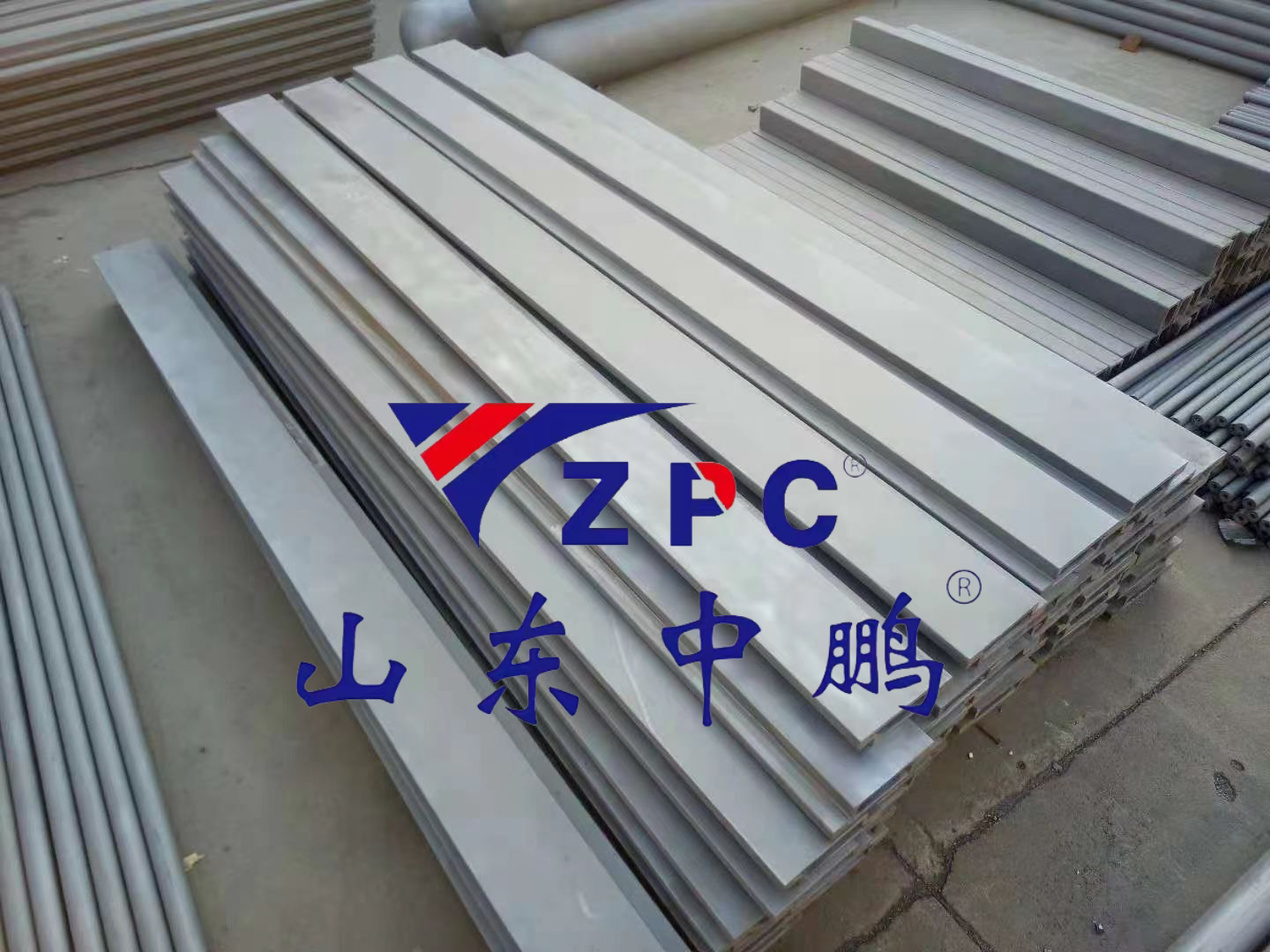

Silicon carbide matanda

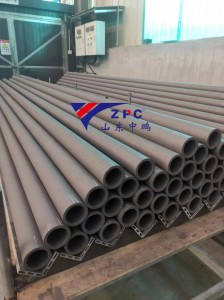

Reaction-sintered silicon carbide (R-SiC) ceramic rollersdzakabuda sezvikamu zvakakosha mumasisitimu emazuva ano ekupisa, kunyanya mukugadzira lithium bhatiri, kugadzirwa kweceramics yepamusoro, uye chaiyo magineti sintering. Aya akasarudzika ma roller anotsanangudza maitiro ekuita mune yakakwirira-tembiricha maindasitiri nekugadzirisa matambudziko akakosha mukugadzikana kwekupisa uye kusimba kwemuchina.

Unmatched Thermal Performance

Yakagadzirwa kuti irambe ichishanda pa1450-1600 ° C - yakanyanya kukwirisa kupfuura yechinyakare alumina rollers - R-SiC rollers inochengetedza dhimensional chaiyo kunyangwe pasi pekunyanya kupisa bhasikoro. Yavo yakasarudzika microstructure inogonesa:

• Kurumidza kutamisa kupisa kufanana (±5°C kureba kwemarola)

• Kutsungirira 100+ thermal shock cycles (1400°C ↔ tembiricha yekamuri)

• Zero creep deformation patembiricha yakadzikama

Critical Applications Yakatsanangurwa Patsva

1. Lithium Battery Production

- Kurongeka chaiko kwe electrode zvinhu sintering

-Kubata-kusasvibiswa kwekubata kweNMC/LFP cathodes

- Kushanda kwakagadzikana mukuderedza mamiriro ekunze

2. Advanced Ceramics Processing

-Warp-yemahara tsigiro yeakakura-fomati mataira (anosvika 1.5 × 3m)

- Inopindirana yekumhanyisa kudzora mune sanitaryware glazing mitsetse

-Kusina-kumaka pamusoro pekupedzisira (Ra <0.8μm)

3. Magnetic Material Manufacturing

-Vibration-yemahara kutenderera kune yakatarisana ferrite sintering

-Kemikari inertness munzvimbo ine hydrogen-yakapfuma

Operational Advantages

Kutakura Kukwanisa: Inotsigira 3-5 × huremu hukuru pane imwe unit urefu vs. metal alloy rollers

Deformation Resistance: Inochengetedza <0.05mm/m kutwasuka mushure me10,000 maawa ekushanda

Kushanda Kwesimba: 18-22% yakaderedza mashandisirwo emagetsi echoto kuburikidza neyakagadziriswa kupisa kugovera

Cross-Industry Compatibility: Inochinjika kune shuttle kilns, multi-layer roller heartths, uye hybrid tunnel mavira.

Economic Sustainability

Ipo ichida 30-40% yepamusoro pekutanga kudyara pane yakajairwa rollers, R-SiC mhinduro dzinoratidza:

- 70% yakareba sevhisi nguva (5-7 makore vs. 2-3 makore)

- 90% recyclability kuburikidza nemafuta ekudzoreredza maitiro

- 60% yakaderera mari yekugadzirisa kubva kune abrasion-inodzivirira nzvimbo

Ramangwana-Yakagadzirira Dhizaini

Yemazuva ano R-SiC rollers ikozvino inosanganisira:

- Laser-yakavezwa yekutevera migero yeotomatiki mitsara yekugadzira

-Customizable porosity kune chaiyo mhepo permeability

- Yakabatanidzwa inopisa sensors ye smart kiln mashandiro

Aya tekinoroji kufambira mberi anomira-sintered silicon carbide rollers sezvinhu zvakakosha mune inotevera-chizvarwa maindasitiri ekudziya masisitimu, zvichiita kuti vagadziri vakwanise kudzikamisa tembiricha yekudzora, yepamusoro yechigadzirwa kusarongeka, uye inoenderera kugadzirwa kwekushanda munzvimbo dzakawanda dzepamusoro-tekinoroji zvikamu.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.