Silicon Carbide Bulletproof Tiles

Silicon carbide ceramics are widely used non oxide ceramics with high hardness, second only to diamonds, cubic boron nitride, and boron carbide. Due to its low density and high hardness, this ceramic is very suitable for ballistic protection. At the same time, it is an intermediate zone between aluminum oxide and boron carbide in terms of mechanical properties, density properties, ballistic properties, and application costs. Valence bonds and high Si-C bond energy enable silicon carbide materials to have high modulus values, high hardness, and high specific strength.

As for silicon carbide, its mechanical properties, density, bulletproof performance, and application cost are between those of aluminum oxide and boron carbide, with a high cost performance ratio. Therefore, it has become one of the bulletproof ceramic materials with current application prospects.

Silicon carbide bulletproof tiles

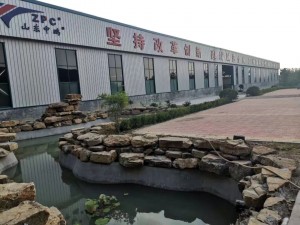

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.