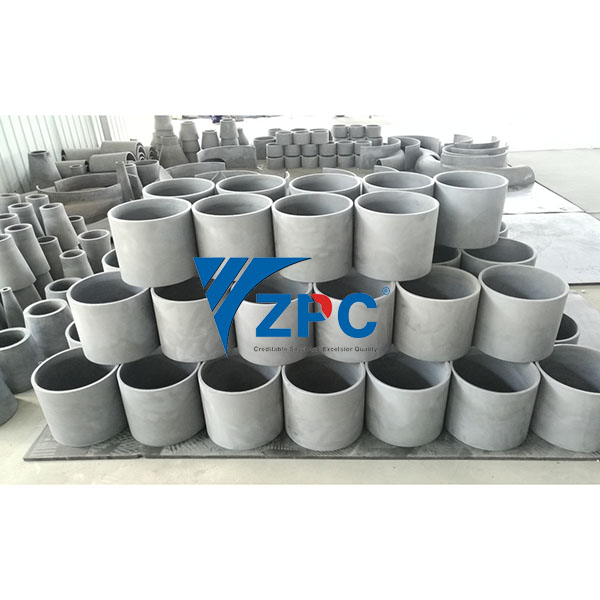

Wear and Abrasion resistance busher/bushing

The silicon carbide ceramic bushing features high sturdiness, superb heat conductivity, resistance to wear, impact, corrosion and high temperature, and a long lifespan six times of polyurethane. It is especially applied to the grading, concentration and dehydration of corrosive and coarse granules in industries of ore dressing, petroleum, water conservation, coal, etc.

Silicon carbide ceramic wear resistantpipe is produced by lining a sintered ceramic pipe inside a steel pipe with adhesive (mostly polyurethane). The bonding between the ceramic lining and the steel pipe is firm and fine, able to endure temperature from -50℃ to 1350℃. The ceramic lining features high rigidity, wear and impact endurance, corrosion resistance, smooth surface, and dust proofness. Its thickness varies from 6 to 25 mm. It is suitable for classification, concentration, dehydration of corrosive and coarse particles. At present, it has been widely used in mineral processing, irrigation works, and electric power industries.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.