Corrosion and Wear Ceramic Tiles, Blocks

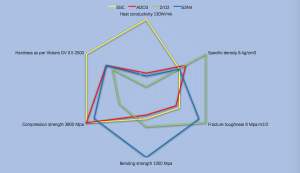

Shandong Zhongpeng Special Ceramics Co., Ltd, specialized in production of SiSiC products for 10 years, and now is one of the biggest SiSiC products manufacturer in China. Reaction bonded silicon carbide (SiSiC) Wear resistant solutions: Moh’s hardness is 9.5 (New Moh’s hardness is 13, open porosity: <0.1%, density:3.05 g/cm3), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes.

- Achieved a lower cost, compared to SSiC tiles.

- Use of fine green SiC powder, excellent wear resistance performance, the service life is more than 5-7 times of alumina.

- Coefficient of Friction is Moderate.

- Large size components can be produced.

Ceramic wear resistant systems Catalog:

Wear resistant ceramic

Wear solutions ceramic

Ceramic wear solutions

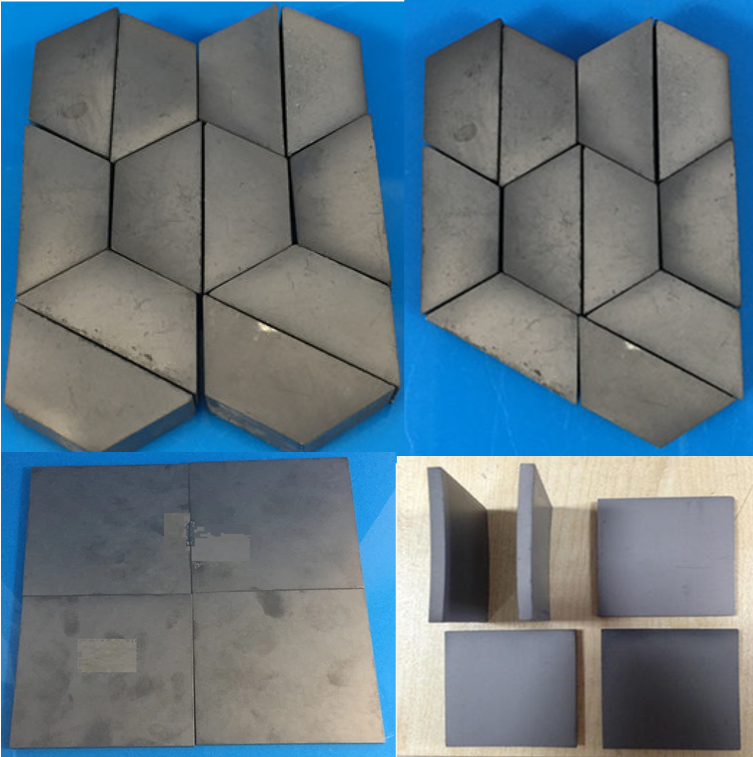

Ceramic wear plates

Wear resistance lining

Ceramic wear protection

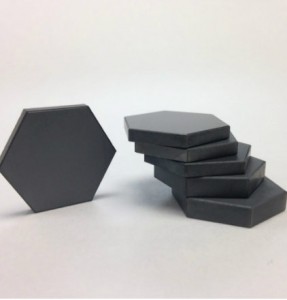

Ceramic wear resistant tile

Ceramic block

Ceramic lined

Wear resistant coatings and linings

Ceramic wear liners

Ceramic lined elbows

Ceramic lined pipe

Ceramic lined tube

Ceramic and steel liners

Wear resistant ceramic composites

High alumina ceramic wear resistant tiles

Ceramic wear tiles

Ceramic chute lining

Ceramic wear and corrosion protection

Alumina ceramic-lined products

Ceramic filled polymer wear products

Ceramic/composite machining services

Ceramic wear products

Wear protection to mining operations

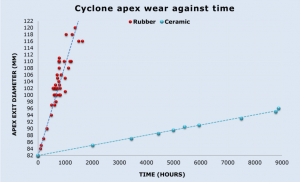

Mining cyclone wear protection solutions

Rubber backed ceramic tiles

Engineered ceramic solutions

Corrosion & wear ceramic

Wear and corrosion protection with advanced ceramics

Mining, gravel and dredging wear solutions

Corrosion resistant ceramics

Corrosion resistance of wear resistant silicon carbide ceramics

Ceramic wear components

Wear & corrosion resistant solutions

Engineered wear solutions

Power generation chute linings

Minerals processing chute linings

Cement chute linings

Chemical chute linings

Steel chute linings

Coal chute lining

Transfer chutes lining

Sluiceways ceramic lining tile

Cyclone ceramic lining

Advanced ceramics-based extreme abrasion and corrosion resistant products

Advanced-ceramic lining systems

Mining wear parts

Wear resistant technical ceramics

Lining pipe wear resistant

Ceramics tiles for wear protection

Industrial ceramics

Industrial ceramic lining

Rubber & ceramic lining

Silicon carbide and alumina ceramic tiles

Ceramic wear resist

Ceramic wear plates

Ceramic sheets & blocks

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.