Liphaephe tsa silicon carbide tse sa haneleng ZPW, lithaele, lipoleiti, likobe, litsoe

Lesela le sa senyeheng, poleiti ea lesela le sefefo se sebelisoang merafong ea mashala

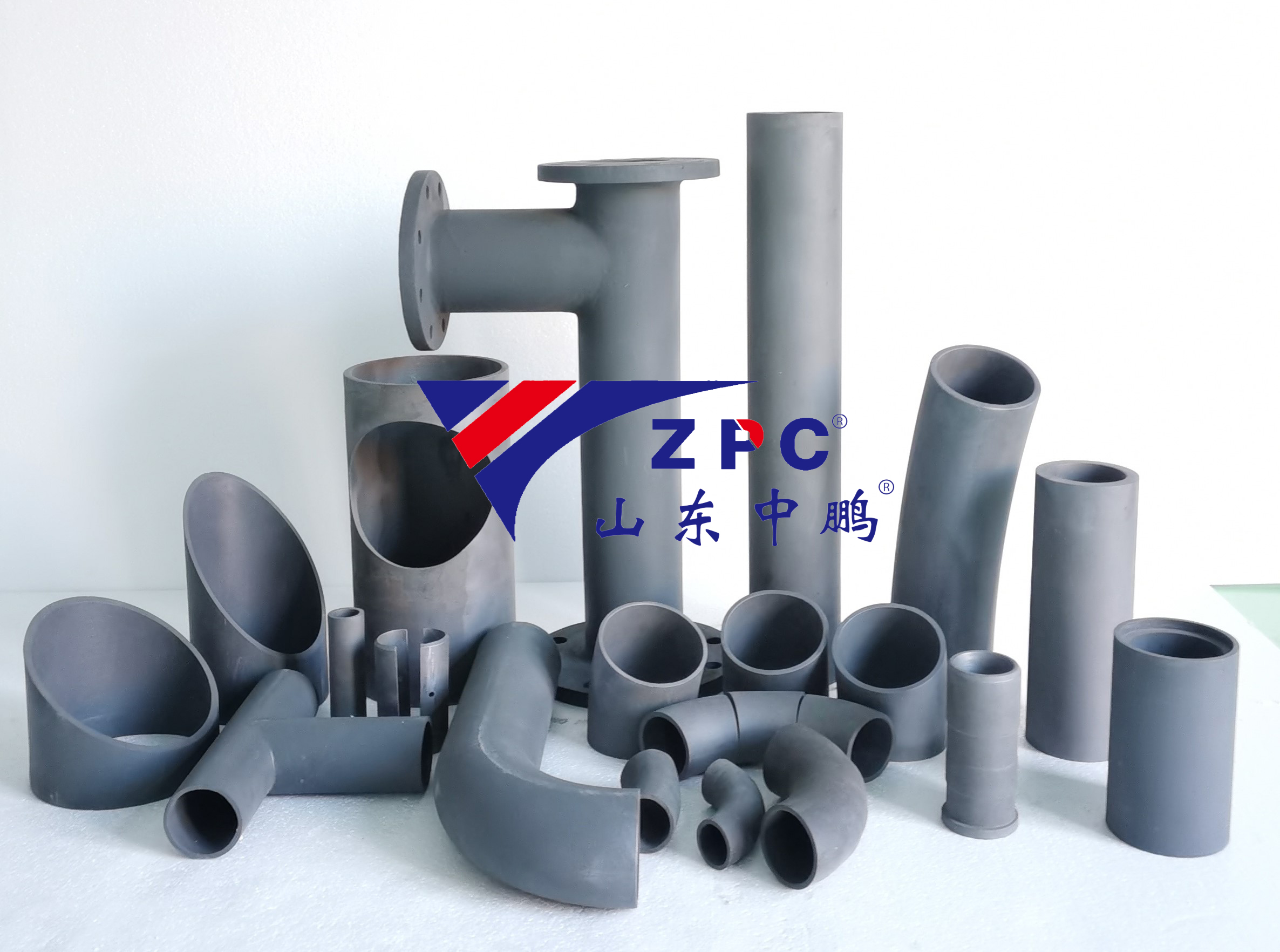

Liphaephe tse koahetsoeng ka ceramic tsa Silicon Carbide:

![]() ZPW-Silicon Carbide ceramic ke thepa e loketseng ho roala, e loketseng haholo bakeng sa ho khohlela ho matla, likaroloana tse mahoashe, ho hlopha, mahloriso, ho felloa ke metsi le mesebetsi e meng.

ZPW-Silicon Carbide ceramic ke thepa e loketseng ho roala, e loketseng haholo bakeng sa ho khohlela ho matla, likaroloana tse mahoashe, ho hlopha, mahloriso, ho felloa ke metsi le mesebetsi e meng.

E sebelisoa haholo indastering ea merafo, indastering ea tšepe, indastering ea ts'ebetso ea likorale, lik'hemik'hale

indasteri, indasteri e etsang thepa e tala, ho tiisa ka mechine, kalafo ea lehlabathe le reflector holim'a metsi jj. Ka lebaka la ho ba thata le ho hanyetsa ho khohlang, e ka sireletsa karolo eo ho hlokahalang tšireletso ea ho roala ho eona ka katleho, e le ho lelefatsa bophelo ba ts'ebeletso ea lisebelisoa.

■Litlhaloso:

| Ntho | Yuniti | Lintlha |

| Mocheso oa ts'ebeliso | ℃ | 1380℃ |

| Botenya | G/cm3 | >3.02 |

| Maro a bulehileng | % | 0.1 |

| Matla a ho kobeha -A | Mpa | 250 (20℃) |

| Matla a ho kobeha -B | MPa | 280 (1200℃) |

| Modulus ea ho tenyetseha-A | GPa | 330(20℃) |

| Modulus ea ho tenyetseha -B | GPa | 300 (1200℃) |

| Ho khanna ha mocheso | W/mk | 45 (1200℃) |

| Tekanyo e sebetsang ea katoloso ea mocheso | K-1 ×10-6 | 4.5 |

| Ho tiea | / | 13 |

| Alkaline e sa keneng ka asiti | / | e babatsehang |

■Sebopeho le boholo bo fumanehang:

Botenya: ho tloha ho 6mm ho isa ho 25mm

Sebopeho se Tloaelehileng: Poleiti ea SISIC, Phaephe ea SISIC, Lihokelo tse Tharo tsa SiSiC, Setsoe sa SISIC, Leholiotsoana la Khoune ea SISIC.

Tlhokomeliso: Boholo le sebopeho tse ling lia fumaneha ha ho kopuoa.

■Sephutheloana:

Ka lebokoseng la lebokose, le pakiloe ka har'a pallet ea lehong e fumisitsoeng ka oli e boima ba 20-24MT/20′FCL.

■Melemo ea bohlokoa:

1. Ho hanyetsa ho tsofala ho babatsehang, ho hanyetsa tšusumetso le ho hanyetsa ho bola;

2. Ho batalla haholo le ho hanyetsa mocheso hantle ho fihlela ho 1350℃

3. Ho kenya habonolo;

4. Bophelo ba tšebeletso bo bolelele (bo feta ba alumina ceramic ka makhetlo a 7 le ka makhetlo a 10 ho feta ba

polyurethane

Moralo oa phaephe e nang le lesela la letsopa:

Lisebelisoa tsa Ceramic: RBSiC, SiSiC, SSiC, 99.5% Alumina, 99% Alumina, 95% alumina

- Liphaephe, tlhahiso ka kakaretso;

- Lipoleiti, poleiti e khanyang

- Lithaele, lithaele tsa ceramic.

Paterone ea ho senyeha ha khutlo Ho senyeha ho thellang ha khutlo e tlase

Ha phallo ea thepa e khorofo e otla bokaholimo ba ho tsofala ka sekhutlo se sa tebang kapa e feta ka lehlakoreng le leng, mofuta oa ho tsofala ho hlahang khohlanong o bitsoa ho thella ha ho thella.

Li-ceramic tsa silicon carbide tse tsoetseng pele li fana ka ho hanyetsa ho tsofala le ho hanyetsa ho tsofala ha lithaele tsa ceramic le lesela. Lihlahisoa tsena li pakiloe hore lia tsofala ha lisebelisoa ts'ebetsong ea ho tsamaisa, ho sebetsana le ho boloka. Lithaele tsa rona li ka hlahisoa ka botenya ho tloha ho 8 ho isa ho 45mm. Ho bohlokoa ho netefatsa hore u ka fumana lihlahisoa tse hlokahalang. SiSiC: Bothata ba Moh ke 9.5 (Bothata ba Moh bo bocha ke 13), bo nang le ho hanyetsa ho tsofala le ho tsofala, ho taboha ho hoholo - ho hanyetsa le ho thibela oxidation. E matla ka makhetlo a 4 ho isa ho a 5 ho feta nitride bonded silicon carbide. Bophelo ba ts'ebeletso bo bolelele ka makhetlo a 5 ho isa ho a 7 ho feta thepa ea alumina. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Lesela la ceramic le hanyetsang ho tsofala lea tsamaisa ho ntlafatsa ts'ebetso ea tlhahiso, bokhoni ba ho sebetsa, phokotso ea litšenyehelo tsa tlhokomelo le phaello e eketsehileng.

Diserame tse nepahetseng di na le tsebo ya dintho tse bonahalang, boiphihlelo bo sebedisitsweng le bokgoni ba boenjiniere. Sena se ka netefatsa ka katleho hore ditharollo tse ntle di fanwa ho bareki ba rona. Dithaele tsa ceramic tsa silicon carbide le lesela la ho kenya di atisa ho sebediswa ditshebedisong tse kang diholiotsoana, di-tube, di-chute, di-hopper, diphaephe, mabanta a ho tsamaisa le ditsamaiso tsa tlhahiso. Tsamaisong, ho na le dintho tse tsamayang tse thellang hodima bokahodimo. Ha ntho e thella hodima thepa, e senya dikarolo butle-butle ho fihlela ho se na letho le setseng. Dibakeng tse nang le ho tsofala haholo, sena se ka etsahala kgafetsa mme sa baka mathata a mangata a turang. Sebopeho se seholo se bolokwa ka ho sebedisa thepa e thata haholo, jwalo ka diserame tsa silicon carbide le diserame tsa alumina e le lesela la sehlabelo. Ka nako e ts'oanang, diserame tsa silicon carbide di ka mamella ho tsofala nako e telele pele di hloka ho nkelwa sebaka, bophelo ba tshebeletso ya ceramic ya silicon carbide bo bolelele ka makgetlo a 5 ho isa ho a 7 ho feta thepa ya alumina.

Lithaele tsa Ceramic tse sa Khaotseng ho Roala tsa Silicon Carbide le Thepa ea ho Roala:

E hanela lik'hemik'hale

E sireletsang mocheso ka motlakase

E hanela khoholeho ea metjhini le ho khoholeha

E ka nkeloa sebaka

Melemo ea Lithaele le Li-Lining tse Hanelang ho Tloha ka Ceramic:

E ka sebelisoa moo ho hlokahalang mamello e tiileng kapa masela a masesaane

E ka sebelisoa ho tsosolosa libaka tse seng li ntse li tsofala

E ka sebelisoa ka mekhoa e mengata ea ho hokela joalo ka ho tjheseletsa le likhomaretsi

E etselitsoe lits'ebetso tse ikhethileng

E hanela mafome haholo

Tharollo ea ho fokotsa ho robeha ha bobebe

E sireletsa likarolo tse tsamaeang tse ka bang kotsing ea ho senyeha haholo

E tšoarella nako e telele haholo ebile e sebetsa hantle ho feta litharollo tsa ho fokotsa ho tsofala

Mocheso o phahameng ka ho fetisisa oa tšebeliso o fihlang ho 1380°C

1. Indasteri ea tšepe

Sistimi ea ho fetisa: lebili la bakete Bai, diski, hopper Du, silo, apron ea conveyor ea lebanta, tee ea trolley, hopper e amohelang

Sistimi ea ho kopanya: silo ea ho kopanya, silo ea mantlha ea ho kopanya ea Dao, silo ea bobeli ea ho kopanya, disc ea ho kopanya, moropa oa ho kopanya, scraper, poleiti ea pelletizing

Sistimi ea ho sintering: hopper ea melemo tlas'a skrine e thothomelang, chute ea lipalangoang tsa thepa e tala, pokello ea lerōle la sefefo le phaephe, impeller ea fan

2. Indasteri ea samente:

Sistimi ea ho sila kalaka le sistimi ea ho kopanya mafura e tala le e tala: chute, hopper, moropa oa lebanta

Sistimi ea tšilo e tala: thae ea karohano ea tataiso, khoune ea karohano, tšilo e otlolohileng ho ea ho tube ea sefefo, sefefo, tšilo ea mafura (silo ea tšepe ea bolo), ntlo ea karohano, khoune e ka hare, phala ea mashala e silafalitsoeng

Selei sa mafura (selei sa tšepe): ntlo ea karohano, khoune e ka hare, phala ea mashala e silafalitsoeng, phala ea ho khutlisa phofo

3. Indasteri ea likou

Sehokelo se tsitsitseng bakeng sa sebaka sa ho robala, sehokelo bakeng sa mochini oa lebili la bakete, sehokelo se tsitsitseng bakeng sa seteishene sa phetisetso ea lebanta, sehokelo bakeng sa sesebelisoa sa ho jarolla thepa ka sekepeng

4. Indasteri ea ho qhibilihisa

Sistimi ea ho fetisa: chute ea hlooho, silo (nkho e bohareng, nkho ea mohatla), setshelo sa skrine se thothomelang, hopper ea coke, hopper ea metering

Sistimi ea ho kopanya: hopper ea ho kopanya, motsoako oa mantlha (oa bobeli)

Sistimi ea ho besa: pompo ea lithōle tse le 'ngoe, tube ea calcine, hopper ea batching, hopper ea molora, hopper ea lithōle tse mahareng

5. Indasteri ea lik'hemik'hale:

Sistimi ea ho fetisa: hopper, silo

Sistimi ea ho tlosa lerōle: phaephe ea ho tlosa lerōle, setsoe, sekotjana sa fene le impeller, sefefo

6. Indasteri ea mashala:

Sistimi ea ho sebetsana le mashala: chute, hopper, silo

Sistimi ea ho hlatsoa mashala: sefefo se nang le khatello, sefefo se boima se mahareng se se nang khatello, sefefo se boima se mahareng se se nang khatello, sehlopha sa sefefo se matla se mahareng se se nang khatello

Sistimi ea ho fetisa: phaephe, setsoe, phaephe, hopper, silo, koung ea kabo

7. Indasteri ea merafo:

Hydrocyclone, li-spigot, ntlha, liphaephe, litsoe, li-kobeha

Liseramike tse sa bonahaleng

E hanelang ho roala

Leholiotsoana la Morafo

PU e kopaneng

Polyurethane e kopantsoeng

Tšepe e nang le Mehele ea Sisic

Sesepa sa letsopa se sa bonahaleng

Sekoahelo se sireletsang sa SISIS

Sleeve e sireletsang ea RBSIC

Silicon Carbide Burner Nozzle

Silicon Carbide Nozzle Tube

Lisebelisoa tsa E-sakerete

Liseramike tse sa bonahaleng

Thepa ea ka tlung ea kiln

Khanyetso ea Mocheso o Phahameng

Karabelo e Kopantsoeng ea Silicon Carbide

Lisebelisoa tsa tšireletso ea sesole

Ho thibela ho phunya

Tšireletso ea ho Abrasion

E hanela

Ts'epe e sa beng le mabali

E entsoe Chaena, e sa senyeheng, e hanelang ho roala, e kopanya polyurethane le letsopa

China Compound PU

Polyurethane e kopantsoeng ea Chaena

Alumina Ceramic

Phaephe

1650c Tube ea Sic ea Mocheso o Phahameng

E entsoe Chaena e sa Tshabeng ho Tshabisa Ceramic Composite PU

Li-ceramics tsa Silicon Carbide tse Hloahloa tse Phahameng

Lesale la Carbide le Phahameng la Silicon le Hloekileng

Likarolo tse sa tloaelehang tsa Silicon Carbide Ceramic

Likarolo tsa letsopa

Lisebelisoa tsa Ceramic tsa Silicon Carbide

Lisebelisoa tsa Ceramic

E entsoe Chaena, Tšepe e nang le Ceramic Composite Sisic Lined Steel e sa Tloheng

Karolo ea letsopa

E entsoe Chaena ka bongata, e netefalitsoe ka bongata, e hanela ho roala, e hanela ho roala, e nang le ceramic composite polyurethane

Boima bo Phahameng

92% Alumina

E entsoe Chaena, Polyurethane e Kopantsoeng ea Ceramic Composite e Hanelang ho Tloha Liindastering

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.