Imiqadi yeSiC

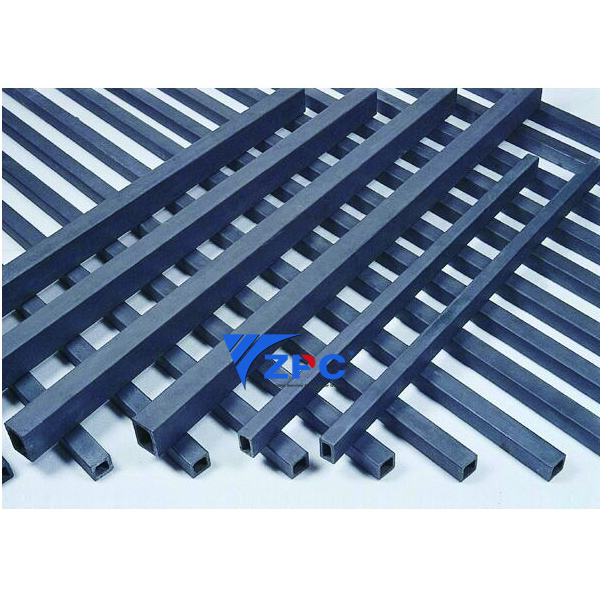

I-Reaction Bonded Silicon Carbide Amandla Aphezulu Ukuthe Tye Okuphezulu Iirola kunye neeBeams ze-Sisic/Rbsic

I-reaction sintering silicon carbide ceramics roller isetyenziselwa kakhulu imboni yebhetri ye-lithium, i-porcelain yemihla ngemihla, i-porcelain yococeko, ii-ceramics zokwakha kunye nezixhobo zemagnethi, ezifana ne-roller kiln, ukutsha kobushushu obuphezulu kunye ne-oven efanelekileyo, enobomi obude benkonzo. Inamandla obushushu obuphezulu, ukumelana nokutsha kobushushu, ukumelana nokuqhekeka kobushushu obuphezulu, ukumelana okunamandla, ukumelana nokuguguleka okuhle. Ii-rollers ezinomthamo wokuthwala ubushushu obuphezulu, osetyenziswa ixesha elide ngaphandle kokuguquguquka kokugoba, zifanelekile ngakumbi kwii-tunnel kilns, i-shuttle kiln, kwi-roller kiln enezingqimba ezimbini kunye nezinye izakhiwo ze-industrial furnace load-bearing structure zesakhelo.

Iiklabhu zisebenza kwi-ceramics ezisetyenzisiweyo zemihla ngemihla, i-porcelain yococeko, i-Building Ceramic, izinto ze-Magnetic kunye nendawo yokutshisa enobushushu obuphezulu ye-roller kiln.

| Inkcazelo yeMveliso yeSilicon Carbide: | ||||

| Into | Iyunithi | I-SSIC | I-RBSIC SISIC | I-R-SIC |

| Ubunyulu | (%) | ≥ 99 | ≥90% | ≥ 99 |

| Ubushushu besicelo | ºC | 1700 | 1380 | 1650 |

| Uxinano | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| I-Porosity evulekileyo | % | ≤0.1 | ≤0.1 | |

| Ukuqina | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Amandla okugoba | I-MPa | 400-580 | 250(20ºC) | ≥300 |

| 281(1200ºC) | ||||

| Tensile strength | I-Mpa | ≥200 | ≥190 | |

| imodulus yokuqina | I-GPa | 400 | 332(20ºC) | 80-100(20ºC) |

| 300(1200ºC) | 90-110(1200ºC) | |||

| Ukuqhuba kweThermal | W/mk | 100-120 | 45(1200ºC) | 36 |

| I-coefficient yokwandiswa kobushushu | I-K1X 106 | 4.2 | 4.5 | 4.6 |

| Ukuqina | I-Gpa | >25 | 13 | |

| Ukumelana ne-Acid kunye ne-Ikali | Igqwesile | Igqwesile | Igqwesile | |

| Iinkcukacha zeMveliso yeSiC: | ||||

| Into | Iyunithi | OC-1 | OC-2 | MC-3 |

| I-SiC | (%) | ≥90 | ≥86 | ≥80 |

| Ukuqhekeka Okubonakalayo | (%) | ≤10 | ≤13 | ≤16 |

| Uxinano | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Ubushushu besicelo | ºC | ≥1680 | ≥1620 | ≥1550 |

| I-coefficient yokwandiswa kobushushu | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Amandla Okugoba | 1200ºC | ≥45 | ≥40 | ≥30 |

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.