Iirola zeSilicon Carbide

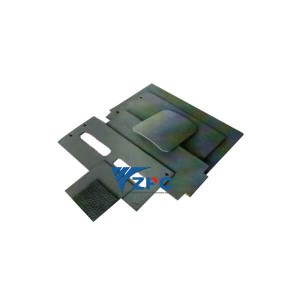

Ngeempawu zamandla aphezulu, ukumelana nobushushu obuphezulu, ubulukhuni obuphezulu, ukumelana nokuguguleka okuphezulu, ukumelana nokugqwala, ukumelana ne-oxidation, ukumelana noxinzelelo lobushushu, ukuqhuba kakuhle kobushushu kunye nokusebenza kakuhle kobushushu. Ubomi bokuphila bungaphezulu kwezihlandlo ezili-10 zemibhobho yentsimbi engagqwali.

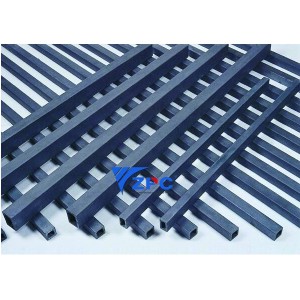

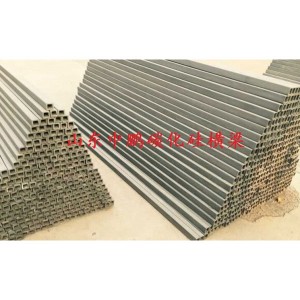

Iibhanti ze-silicon carbide kunye neerola zisetyenziswa njengeefreyimu zokulayisha kwii-ovens ezivelisa i-porcelain, kwaye zinokuthatha indawo yeplate ye-silicon edibeneyo ye-oxide kunye ne-mullite post eqhelekileyo kuba zineengenelo ezilungileyo ezifana nokugcina izithuba, ipetroli, amandla kunye nokukhawulezisa ixesha lokutshisa, kwaye ubomi bale nto buphindwe kaninzi kunezinye, yifenitshala ye-oven efanelekileyo kakhulu.

Imiqadi enomthamo wokuthwala ubushushu obuphezulu osetyenziswa ixesha elide ngaphandle kokuguquka okugobileyo, ifanelekile ngakumbi kwii-kilns ze-tunnel, i-shuttle kiln, kwi-roller kiln enezitezi ezimbini kunye nezinye izakhiwo ze-industrial furnace-load zesakhiwo sesakhelo.

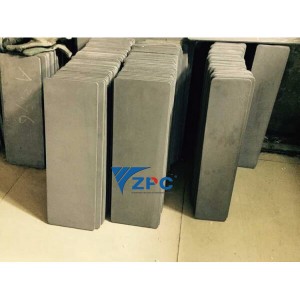

Iiklabhu zisebenza kwi-ceramics ezisetyenzisiweyo zemihla ngemihla, i-porcelain yococeko, i-Building Ceramic, izinto ze-Magnetic kunye nendawo yokutshisa i-roller kiln enobushushu obuphezulu.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.